This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

A wiring harness is a collection of wires, connectors, and components that transmit electrical power and signals throughout a vehicle. It consists of insulated wires bundled together, often secured with ties or conduits, and includes various connectors, terminals, and splices. The primary function of a wiring harness is to ensure efficient and reliable electrical connections within the vehicle, facilitating communication between different systems and components. By centralizing and organizing the wiring, harnesses reduce the complexity of the electrical system, enhance safety, and improve overall vehicle performance 1.

Purpose of the Cummins 2870073 Wiring Harness

The Cummins 2870073 Wiring Harness is designed specifically for use in commercial trucks. It plays a significant role in the operation of these vehicles by connecting various electrical components and subsystems. This harness ensures that power and signals are distributed correctly throughout the truck’s electrical system, supporting functions such as engine management, lighting, instrumentation, and other critical systems. By providing a structured and organized method for electrical distribution, the Cummins 2870073 Wiring Harness helps maintain the reliability and efficiency of the truck’s electrical network 2.

Key Features of the Cummins 2870073 Wiring Harness

The Cummins 2870073 Wiring Harness is engineered with several key features that enhance its performance and durability in heavy-duty applications. Its design incorporates high-quality materials resistant to wear, corrosion, and environmental factors, ensuring long-term reliability. The harness is constructed with precision to fit snugly within the truck’s chassis, reducing the risk of damage from vibrations or movement. Additionally, it includes robust connectors and terminals that provide secure and stable electrical connections, minimizing the potential for faults or failures 3.

Benefits of Using the Cummins 2870073 Wiring Harness

Incorporating the Cummins 2870073 Wiring Harness into commercial trucks offers several advantages. One of the primary benefits is improved reliability, as the harness is designed to withstand the rigors of heavy-duty use. This results in reduced maintenance requirements, as the harness is less likely to experience issues such as electrical shorts or connector failures. Furthermore, the enhanced performance of the vehicle’s electrical system contributes to overall truck efficiency, ensuring that all electrical components operate smoothly and effectively 4.

Installation and Compatibility

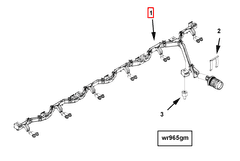

When installing the Cummins 2870073 Wiring Harness, it is important to follow guidelines and considerations to ensure proper fit and function. The harness is designed to be compatible with various commercial truck models and engine types, but it is crucial to verify compatibility before installation. Proper installation involves securing the harness within the truck’s chassis, ensuring all connections are tight and secure, and protecting the wiring from potential damage. Detailed instructions and diagrams are typically provided to assist with the installation process 5.

Troubleshooting Common Issues

Wiring harnesses can encounter various issues over time, such as electrical shorts, corrosion, and connector failures. To address these problems, it is important to follow systematic troubleshooting procedures. Begin by inspecting the harness for visible signs of damage or wear. Check all connections to ensure they are secure and free from corrosion. If an electrical short is suspected, use a multimeter to test for continuity and identify the source of the issue. Regular maintenance and inspections can help prevent many common problems 6.

Maintenance Tips

To ensure the long-term reliability and performance of the Cummins 2870073 Wiring Harness, regular maintenance is recommended. Inspect the harness periodically for signs of wear, corrosion, or damage. Clean the connectors and terminals to remove any dirt or debris that could affect electrical connections. Protect the harness from environmental factors such as moisture, extreme temperatures, and physical damage. Following these best practices will help maintain the integrity of the wiring harness and ensure continued reliable operation 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for innovation, quality, and customer satisfaction in the automotive and commercial vehicle industries. The company is committed to providing reliable and efficient power solutions, supported by a comprehensive range of products and services designed to meet the diverse needs of its customers 8.

Cummins Wiring Harness 2870073 Compatibility

The Cummins Wiring Harness part number 2870073 is designed to be compatible with a range of Cummins engines, ensuring seamless integration and reliable performance. This wiring harness is engineered to meet the specific electrical needs of various Cummins engine models, facilitating efficient power distribution and control.

ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250

The ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250 engines benefit from the precise electrical connections provided by the 2870073 wiring harness. This harness is tailored to handle the complex electrical requirements of these engines, ensuring optimal performance and reliability.

QSX11.9 CM2250 ECF

The QSX11.9 CM2250 ECF engine also integrates smoothly with the Cummins Wiring Harness part number 2870073. This compatibility ensures that the engine’s electrical systems are efficiently managed, contributing to the overall functionality and durability of the engine.

By providing a robust and reliable connection, the 2870073 wiring harness supports the intricate electrical architecture of these Cummins engines, enhancing their operational efficiency and longevity 9.

Role of Part 2870073 Wiring Harness in Engine Systems

The 2870073 Wiring Harness is an integral component in the orchestration of various engine systems, ensuring seamless communication and power distribution among them. This harness is meticulously designed to interface with a multitude of engine components, facilitating their efficient operation.

Integration with Engine Components

Fuel System

The wiring harness connects to the fuel injectors, providing them with the necessary electrical signals to dispense fuel in precise quantities. It also interfaces with the fuel pump, ensuring it operates at optimal levels to maintain consistent fuel pressure.

Ignition System

In the ignition system, the harness plays a pivotal role by delivering power to the ignition coils. It ensures that the spark plugs receive the correct voltage at the right moment, igniting the air-fuel mixture within the combustion chambers.

Engine Control Unit (ECU)

A significant aspect of the harness’s function is its connection to the ECU. It transmits data from various sensors throughout the engine, allowing the ECU to make real-time adjustments to engine performance. This includes monitoring engine temperature, air intake, and exhaust emissions.

Sensors and Actuators

The harness is the conduit for numerous sensors and actuators within the engine system. It carries signals from oxygen sensors, throttle position sensors, and camshaft position sensors, among others. Actuators such as the idle air control valve and variable valve timing solenoid also rely on the harness for their operation.

Emission Control Systems

In emission control, the wiring harness is responsible for powering components like the catalytic converter and ensuring the proper function of the exhaust gas recirculation (EGR) system. It also connects to the oxygen sensors post-catalytic converter to monitor emissions.

Auxiliary Systems

Beyond the primary engine functions, the harness extends to auxiliary systems. It powers the engine cooling fan, ensuring the engine does not overheat, and connects to the air conditioning compressor, enhancing driver comfort.

Wiring Accessories

Lastly, the harness incorporates wiring accessories that protect and organize the wires. This includes wire looms, grommets, and connectors, which safeguard the wires from abrasion and environmental factors, ensuring longevity and reliability of the electrical connections.

In summary, the 2870073 Wiring Harness is a fundamental component that ensures the harmonious operation of various engine systems. Its role in power distribution and signal transmission is essential for the engine’s performance, efficiency, and compliance with emission standards 10.

Conclusion

The Cummins 2870073 Wiring Harness is a critical component in the electrical system of commercial trucks, ensuring reliable and efficient operation of various engine systems. Its design, featuring high-quality materials and robust connectors, contributes to the durability and performance of the truck’s electrical network. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, ultimately leading to enhanced vehicle efficiency and reliability.

-

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ -

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing, 2011.

↩ -

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ -

Cummins Inc. ISB CM2150 and ISB CM2150 E, Service Manual (4021578).

↩ -

Cummins Inc. ISB CM2150 and ISB CM2150 E, Service Manual (4021578).

↩ -

Cummins Inc. ISB CM2150 and ISB CM2150 E, Service Manual (4021578).

↩ -

Cummins Inc. ISB CM2150 and ISB CM2150 E, Service Manual (4021578).

↩ -

Cummins Inc. Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. ISB CM2150 and ISB CM2150 E, Service Manual (4021578).

↩ -

Cummins Inc. ISB CM2150 and ISB CM2150 E, Service Manual (4021578).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.