This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

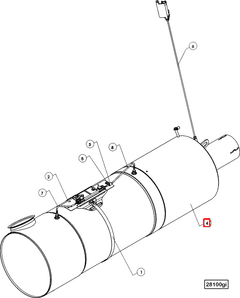

The Cummins 2871593 After Treatment Device is a component designed for use in commercial trucks. It serves to reduce emissions and ensure that the vehicle complies with environmental regulations. This device integrates into the truck’s exhaust system, playing a significant role in the overall operation and efficiency of the engine.

Basic Concepts of After Treatment Devices

After treatment devices are systems installed in the exhaust pathways of vehicles to reduce the level of pollutants emitted into the atmosphere. These devices work by filtering out harmful substances from the exhaust gases before they are released. In heavy-duty trucks, after treatment devices are essential for meeting stringent emissions standards and for maintaining the performance and longevity of the engine 1.

Purpose of the Cummins 2871593 After Treatment Device

The Cummins 2871593 After Treatment Device is specifically engineered to reduce emissions from commercial trucks. It helps in ensuring compliance with environmental regulations by significantly lowering the output of harmful pollutants. Additionally, it contributes to enhancing engine performance by optimizing the exhaust flow and reducing the backpressure on the engine 2.

Key Features

The Cummins 2871593 After Treatment Device incorporates several design elements and technological innovations that enhance its functionality. It is constructed using durable materials to withstand the harsh conditions of commercial truck operations. Key features include advanced filtration technology, efficient catalyst systems, and a robust housing designed to protect internal components from damage 3.

Benefits

The advantages of the Cummins 2871593 After Treatment Device include improved fuel efficiency due to optimized exhaust flow, reduced maintenance costs thanks to its durable construction, and extended engine life as a result of lower emissions and reduced strain on the engine components.

Installation Process

Installing the Cummins 2871593 After Treatment Device involves several steps. It requires ensuring that the truck’s exhaust system is clean and free of obstructions. The device must be securely mounted and connected to the exhaust system, following manufacturer guidelines for alignment and sealing. Tools required may include wrenches, sealants, and possibly a lift for easier access to the exhaust system.

Operational Mechanism

The Cummins 2871593 After Treatment Device operates through a combination of chemical and physical processes to reduce emissions. It utilizes catalysts to convert harmful gases into less harmful substances and employs filters to trap particulate matter. The device’s operation is monitored by the truck’s engine control unit, which adjusts the device’s functions based on driving conditions and emissions output.

Troubleshooting and Maintenance

Common issues with the Cummins 2871593 After Treatment Device may include clogging of filters, catalyst degradation, or sensor malfunctions. Diagnostic procedures involve checking for error codes, inspecting physical components for damage, and testing sensor outputs. Regular maintenance includes cleaning or replacing filters, inspecting catalysts for efficiency, and ensuring all connections are secure and leak-free.

Environmental Impact

The Cummins 2871593 After Treatment Device contributes to environmental protection by significantly reducing the emission of harmful pollutants from commercial trucks. This reduction in emissions leads to improved air quality and helps in mitigating the environmental impact of transportation.

Regulatory Compliance

The Cummins 2871593 After Treatment Device assists trucks in meeting emissions standards and regulations, both nationally and internationally. By reducing the output of pollutants, it ensures that vehicles comply with the legal limits set for emissions, facilitating the operation of commercial trucks in regulated environments.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is committed to innovation and sustainability in engine technology, continuously developing solutions that enhance performance, efficiency, and environmental compatibility.

Role of Part 2871593 After Treatment Device in Engine Systems

The Part 2871593 After Treatment Device is an integral component in modern engine systems, designed to enhance the overall efficiency and environmental performance of the engine. This device works in conjunction with several key components to ensure that emissions are minimized and the engine operates within regulatory standards.

Integration with the Exhaust System

The After Treatment Device is typically positioned within the exhaust system, downstream of the turbocharger and Diesel Oxidation Catalyst (DOC). Its primary function is to further reduce harmful emissions such as Nitrogen Oxides (NOx) and Particulate Matter (PM). By placing it in this location, the device can effectively treat the exhaust gases before they are released into the atmosphere.

Interaction with the Diesel Particulate Filter (DPF)

One of the main components the After Treatment Device interacts with is the Diesel Particulate Filter (DPF). The DPF captures soot and other particulates from the exhaust stream. The After Treatment Device complements this by ensuring that any remaining particulates are further reduced, enhancing the overall filtration efficiency of the system.

Coordination with the Selective Catalytic Reduction (SCR) System

The After Treatment Device also plays a significant role in the Selective Catalytic Reduction (SCR) system. The SCR system injects a urea-based solution into the exhaust stream, which reacts with NOx to convert it into harmless nitrogen and water vapor. The After Treatment Device ensures that this reaction is optimized, thereby maximizing the effectiveness of the SCR system.

Enhancement of the Exhaust Gas Recirculation (EGR) System

In engines equipped with an Exhaust Gas Recirculation (EGR) system, the After Treatment Device works to further reduce NOx levels. The EGR system recirculates a portion of the exhaust gas back into the intake stream to lower combustion temperatures and reduce NOx formation. The After Treatment Device ensures that any NOx that does form is effectively treated, maintaining low emission levels.

Support for the Turbocharger

Although the turbocharger’s primary role is to increase engine efficiency by compressing intake air, its operation can influence exhaust gas temperature and flow. The After Treatment Device is designed to handle these variables, ensuring consistent performance regardless of turbocharger activity.

Contribution to the Overall Engine Management System

The After Treatment Device is often monitored and controlled by the Engine Control Unit (ECU). Sensors provide real-time data on exhaust gas composition and temperature, allowing the ECU to make adjustments to the After Treatment Device’s operation. This ensures that the device is always functioning at peak efficiency, contributing to the engine’s overall performance and emissions compliance.

Conclusion

The Cummins 2871593 After Treatment Device is a critical component in the effort to reduce emissions from commercial trucks. By integrating advanced technologies and durable construction, this part ensures that trucks meet stringent environmental regulations while also enhancing engine performance and efficiency. Regular maintenance and proper installation are essential to maximize the benefits of this device, contributing to both environmental protection and regulatory compliance.

-

G.K. Awari, V.S. Kumbhar, and R.B. Tirpude, Automotive Systems Principles and Practice, CRC Press, 2011.

↩ -

Wilfried J Bartz, Engine Oils and Automotive Lubrication Mechanical Engineering Book 80, CRC Press, 2019.

↩ -

Gus Wright, Fundamentals of Medium-Heavy Duty Diesel Engines, Jones & Bartlett Learning, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.