This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 2871612 After Treatment Device is a component designed to enhance the emissions control system of heavy-duty trucks. Its purpose is to reduce harmful emissions, ensuring compliance with environmental regulations and contributing to a cleaner environment. This device is significant in the context of heavy-duty truck emissions control, as it plays a role in minimizing the environmental impact of diesel engines 1.

Basic Concepts of After Treatment Devices

After treatment devices are systems installed in the exhaust pathways of vehicles to reduce the emissions of pollutants. These devices work by capturing or converting harmful substances in the exhaust gases before they are released into the atmosphere. In heavy-duty trucks, after treatment devices integrate into the exhaust system to enhance emissions control, ensuring that the trucks meet regulatory standards and reduce their environmental footprint 2.

Purpose of the 2871612 After Treatment Device

The Cummins 2871612 After Treatment Device is designed to play a specific role in the operation of a truck by reducing emissions. It functions as part of the emissions control system, working in conjunction with other components to filter out pollutants from the exhaust gases. This device helps trucks comply with environmental regulations by significantly lowering the levels of harmful emissions released into the atmosphere 3.

Key Features

The primary features of the Cummins 2871612 After Treatment Device include its robust design, the use of high-quality materials, and technological innovations that enhance its performance and durability. The device is engineered to withstand the harsh conditions of heavy-duty truck operations, ensuring long-lasting effectiveness. Its design incorporates advanced materials and construction techniques to optimize efficiency and reliability.

Benefits

The Cummins 2871612 After Treatment Device offers several advantages, including improved emissions performance, potential fuel efficiency gains, and long-term cost savings for fleet operators. By effectively reducing emissions, the device helps trucks meet regulatory standards, avoiding fines and penalties. Additionally, its efficient design may contribute to better fuel economy, offering economic benefits to operators over time.

Integration with Other Systems

The Cummins 2871612 After Treatment Device interacts with other components of the truck’s emissions control system, such as the Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR) system. These systems work together to capture and convert pollutants, ensuring that the exhaust gases meet environmental standards before being released. The integration of these systems enhances the overall effectiveness of the truck’s emissions control strategy.

Maintenance and Troubleshooting

Maintaining the Cummins 2871612 After Treatment Device involves regular inspection procedures, cleaning methods, and troubleshooting common issues that may arise. Proper maintenance ensures the device operates efficiently and effectively, prolonging its lifespan and maintaining its performance. Operators should follow manufacturer guidelines for maintenance schedules and procedures to ensure optimal operation.

Environmental Impact

The use of the Cummins 2871612 After Treatment Device contributes to reduced emissions and compliance with environmental standards. By effectively capturing and converting pollutants, the device plays a role in minimizing the environmental impact of heavy-duty trucks. Its implementation supports efforts to improve air quality and reduce the carbon footprint of diesel-powered vehicles.

Technological Advancements

The Cummins 2871612 After Treatment Device incorporates technological innovations that enhance its effectiveness and reliability. These advancements include improved materials, design optimizations, and integration with advanced monitoring systems. Such innovations contribute to the device’s ability to meet stringent emissions standards and operate efficiently under varying conditions.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and commitment to sustainability, Cummins plays a significant role in the heavy-duty truck industry. The company’s focus on emissions control technology demonstrates its dedication to reducing the environmental impact of diesel engines and supporting a cleaner, more sustainable future.

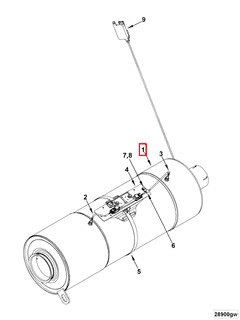

Role of Part 2871612 After Treatment Device in Engine Systems

The After Treatment Device (part 2871612) is integral to the operation of modern engine systems, particularly in ensuring emissions compliance and enhancing engine performance. This component works in conjunction with several other systems and components to achieve optimal results.

Integration with Exhaust Gas Recirculation (EGR) System

The After Treatment Device interacts with the EGR system to reduce nitrogen oxides (NOx) emissions. The EGR system recirculates a portion of the exhaust gas back into the intake manifold, which lowers the combustion temperature and reduces NOx formation. The After Treatment Device then further processes these gases, ensuring they meet emissions standards before being released into the atmosphere.

Coordination with Diesel Particulate Filter (DPF)

In diesel engine systems, the After Treatment Device often works alongside the DPF. The DPF captures particulate matter from the exhaust gases. The After Treatment Device aids in the regeneration process of the DPF by oxidizing soot particles, thereby maintaining the filter’s efficiency and prolonging its service life.

Synergy with Selective Catalytic Reduction (SCR) System

For engines equipped with SCR technology, the After Treatment Device plays a supportive role. The SCR system injects a urea-based solution into the exhaust stream, which reacts with NOx to form harmless nitrogen and water. The After Treatment Device ensures that this reaction is complete and that any remaining pollutants are further reduced.

Interaction with Oxygen Sensors

Oxygen sensors provide feedback on the exhaust gas composition to the engine control unit (ECU). The After Treatment Device ensures that the exhaust gases are within the expected parameters, allowing the oxygen sensors to accurately monitor and adjust the air-fuel mixture for optimal combustion and emissions control.

Contribution to Overall Engine Efficiency

By ensuring that exhaust gases are cleaned effectively, the After Treatment Device contributes to the overall efficiency of the engine. Reduced emissions mean that the engine can operate within regulatory limits without the need for excessive adjustments that might compromise performance or fuel economy.

Enhancement of Turbocharger Performance

In turbocharged engines, the After Treatment Device helps maintain backpressure within acceptable limits. This ensures that the turbocharger can operate efficiently, providing the necessary boost without being hindered by excessive exhaust restrictions.

Conclusion

In summary, the After Treatment Device (part 2871612) is a multifaceted component that enhances the functionality of various engine systems, ensuring both performance and compliance with emissions regulations. Its integration with other systems like the EGR, DPF, and SCR, along with its role in maintaining engine efficiency and turbocharger performance, underscores its importance in modern diesel engine technology.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.