2871960

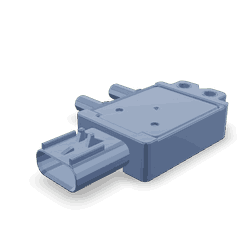

Differential Pressure Sensor

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Understanding the Cummins Differential Pressure Sensor Part #2871960

Introduction to Differential Pressure Sensors

Differential pressure sensors are crucial in modern engines, providing essential data to maintain peak performance and efficiency. These sensors measure the pressure difference between two points, a critical measurement for various engine functions 2.

How a Differential Pressure Sensor Works

A differential pressure sensor operates by detecting the pressure difference across two ports. It typically includes a diaphragm or a piezoresistive element that deforms under pressure. This deformation alters the sensor’s electrical properties, which are then transformed into a measurable signal. The engine control unit (ECU) utilizes this signal to fine-tune fuel injection, air intake, and other parameters, ensuring smooth engine operation 1.

Purpose of the Cummins Differential Pressure Sensor Part #2871960

The Cummins differential pressure sensor part #2871960 is crucial for the operation of commercial trucks. It is engineered to monitor the pressure differential in the exhaust system, which is essential for the efficient functioning of the exhaust gas recirculation (EGR) system. The EGR system reduces nitrogen oxide (NOx) emissions by recirculating a portion of the exhaust gases back into the engine’s intake air. This sensor ensures the EGR valve operates correctly, maintaining optimal engine performance and compliance with emission standards 3.

Role in Truck Operations

In commercial trucks, the differential pressure sensor part #2871960 is vital for balancing performance and emissions control. By accurately measuring the pressure differential, it allows the ECU to adjust the EGR flow, ensuring the engine operates within safe parameters. This sensor is particularly important for heavy-duty trucks, where efficiency and reduced emissions are critical for performance and regulatory compliance 2.

Troubleshooting and Maintenance

Proper maintenance and troubleshooting of the differential pressure sensor part #2871960 are essential for its longevity and reliability. Regular inspections should be conducted to check for signs of wear, corrosion, or damage. If the sensor is faulty, it should be replaced promptly to avoid potential engine issues.

Common troubleshooting steps include:

- Visual Inspection: Examine the sensor and its connections for physical damage or signs of corrosion.

- Electrical Testing: Use a multimeter to test the sensor’s electrical output. Compare the readings with the manufacturer’s specifications to identify any discrepancies.

- Pressure Testing: Ensure the sensor is correctly installed and that there are no leaks in the system that could affect its readings.

Cummins: A Leader in Engine Technology

Cummins is a distinguished manufacturer of engines and related components, renowned for its innovation and reliability. The company has a rich history of developing advanced technologies to enhance engine performance and efficiency. The differential pressure sensor part #2871960 exemplifies Cummins’ dedication to providing high-quality, reliable components that meet the demanding needs of commercial truck operators 3.

Expertise and Authority

Understanding the critical role of components like the differential pressure sensor in the overall operation of a truck is essential for engineers and mechanics. This sensor is a prime example of the advanced technologies Cummins incorporates into its products to ensure optimal performance and reliability. By providing detailed information about the function, purpose, and maintenance of this sensor, we aim to educate and empower those responsible for maintaining these vehicles, ensuring they have the knowledge needed to keep their fleets running efficiently.

Differential Pressure Sensor 2871960 Compatibility with Cummins Engines

The Differential Pressure Sensor 2871960, manufactured by Cummins, is a critical component in the engine management systems of various Cummins engines. This sensor plays a pivotal role in monitoring and regulating the pressure differential across the exhaust system, ensuring optimal engine performance and efficiency.

B4.5 and B6.7 Series

The B4.5 CM2350 B104 and B6.7 CM2350 B135B engines both utilize the Differential Pressure Sensor 2871960. This sensor is integral in these engines for maintaining the balance between the intake and exhaust pressures, which is crucial for the proper functioning of the turbocharger and overall engine performance.

ISB Series

The ISB4.5 CM2350 B104, ISB6.7 CM2250, ISB6.7 CM2350 B101, and ISB6.7 CM2350 B105 engines all incorporate the Differential Pressure Sensor 2871960. This sensor is essential in these engines for ensuring that the exhaust pressure is correctly managed, which directly affects the efficiency of the exhaust gas recirculation (EGR) system and the overall combustion process.

ISC and ISL Series

The ISC8.3 CM2250 and ISL9 CM2250 engines also rely on the Differential Pressure Sensor 2871960. This sensor is critical in these engines for monitoring the pressure differential, which is vital for the proper operation of the EGR system and maintaining the balance between the intake and exhaust pressures.

ISF and ISX Series

The ISF3.8 CM2350 F109, ISX12 CM2350 X102, ISX12/ISX11.9 CM2250, ISX15 CM2250, ISX15 CM2350 X101, and ISX15 CM2250 engines all use the Differential Pressure Sensor 2871960. This sensor is crucial in these engines for ensuring that the exhaust pressure is accurately monitored, which is essential for the efficient operation of the turbocharger and the overall engine performance.

QSB and QSL Series

The QSB3.3 CM2250 EC, QSB6.7 CM2250, QSB6.7 CM2350 B105, QSC9 CM2250/QSL9 CM2250, QSL9 CM2250, and QSL9 CM2350 L102 engines all incorporate the Differential Pressure Sensor 2871960. This sensor is essential in these engines for maintaining the correct pressure differential, which is crucial for the proper functioning of the EGR system and the overall engine efficiency.

QSX Series

The QSX11.9 CM2250 ECF, QSX15 CM2250, QSX15 CM2250 ECF, and QSX15 CM2350 X105 engines all utilize the Differential Pressure Sensor 2871960. This sensor is critical in these engines for ensuring that the exhaust pressure is accurately monitored, which is essential for the efficient operation of the turbocharger and the overall engine performance.

QSG12/X12 Series

The QSG12/X12 CM2350 G110 engine also uses the Differential Pressure Sensor 2871960. This sensor is essential in this engine for maintaining the correct pressure differential, which is crucial for the proper functioning of the EGR system and the overall engine efficiency.

ISV (Nissan)

The ISV (Nissan) engine also incorporates the Differential Pressure Sensor 2871960. This sensor is critical in this engine for ensuring that the exhaust pressure is accurately monitored, which is essential for the efficient operation of the turbocharger and the overall engine performance.

Role of Part 2871960 Differential Pressure Sensor in Engine Systems

The Differential Pressure Sensor, part 2871960, is integral to the effective operation of several components within the engine system. Its primary function is to monitor and relay differential pressure readings, which are essential for the proper functioning of the aftertreatment arrangement.

In the aftertreatment arrangement, this sensor is typically mounted on the aftertreatment bracket, providing a stable and secure location for accurate readings. It works in conjunction with the aftertreatment device, where it measures the pressure differential across the device. This data is vital for assessing the condition and efficiency of the aftertreatment system.

The sensor is also connected to the catalytic converter, where it helps in monitoring the backpressure. This is important for ensuring that the catalytic converter is operating within optimal parameters, thus contributing to the overall efficiency of the engine.

Communication with the Engine Control Module (ECM) is another significant aspect of the Differential Pressure Sensor’s role. The sensor sends real-time data to the ECM, which uses this information to make adjustments to the engine’s operation, ensuring it runs smoothly and efficiently.

The module bracket provides a mounting point for the pressure sensing module, ensuring it is positioned correctly for accurate readings. The sensor bracket, in turn, supports the Differential Pressure Sensor, keeping it in place and protecting it from potential damage.

Conclusion

The Cummins Differential Pressure Sensor part #2871960 is a critical component in the engine management systems of various Cummins engines. It ensures optimal engine performance and efficiency by monitoring and regulating the pressure differential across the exhaust system. Proper maintenance and troubleshooting of this sensor are essential for its longevity and reliability, ensuring the engine operates within safe parameters and complies with emission standards.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.