This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

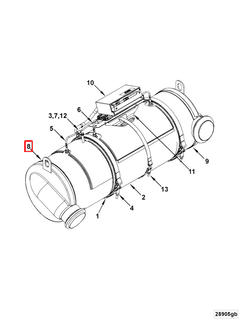

The 2880497 Inlet Catalyst Module, a component designed by Cummins, is integral to the operation of commercial trucks within the exhaust system. Cummins is recognized for its innovation and sustainability, providing solutions that enhance engine performance while adhering to environmental regulations.

Basic Concepts of Inlet Catalyst Modules

An Inlet Catalyst Module is installed in the exhaust system to reduce harmful emissions through catalytic conversion, transforming toxic exhaust gases into less harmful substances. The module contains a catalyst, typically made from precious metals, which accelerates these chemical reactions without being consumed 1.

Purpose of the 2880497 Inlet Catalyst Module

This Cummins part reduces the levels of pollutants emitted, specifically nitrogen oxides (NOx) and particulate matter. It optimizes exhaust flow and reduces backpressure, enhancing engine performance and fuel efficiency 2.

Key Features

The 2880497 is characterized by its robust design and high-quality materials, constructed to withstand high temperatures and pressures. It features a durable housing and a precisely engineered catalyst substrate, ensuring efficient catalytic conversion and longevity. Its design allows for easy integration into the exhaust system 3.

Benefits

Utilizing the 2880497 offers several advantages, including improved fuel efficiency by optimizing exhaust flow, contributing to cost savings. It also reduces emissions, helping vehicles comply with environmental regulations. Its durable construction ensures long-term performance, reducing the frequency of replacements and maintenance costs 4.

Installation Process

Installing the 2880497 involves removing the old module, if present, and installing the new one. This process requires specific tools and may involve adjustments to other exhaust components to ensure a secure fit. Adhering to the manufacturer’s instructions is crucial for successful installation.

Maintenance and Care

Regular maintenance of the 2880497 is essential for optimal performance. This includes periodic inspections for damage or wear, cleaning to remove buildup, and timely replacement if it becomes ineffective. Adhering to these practices ensures the module continues to perform its intended function effectively.

Troubleshooting Common Issues

Common issues with the 2880497 may include reduced efficiency due to contamination or physical damage. Signs of these problems can manifest as increased emissions or decreased engine performance. Troubleshooting steps involve inspecting the module for visible damage, cleaning it to remove contaminants, and, if necessary, replacing it to restore optimal function.

Regulatory Compliance

The 2880497 aids in ensuring that commercial trucks meet emissions regulations. By reducing the levels of harmful pollutants emitted, it helps vehicles comply with environmental laws designed to protect air quality. This compliance is crucial for operators to avoid penalties and contribute to environmental sustainability.

Cummins Overview

Cummins Inc. is renowned for its excellence in manufacturing diesel engines and related components. Founded with a commitment to innovation and sustainability, Cummins consistently delivers high-quality products that meet the demanding requirements of the automotive industry. Its expertise in engine technology and emissions control underscores its role as a leader in providing solutions for commercial vehicles.

Role of 2880497 Inlet Catalyst Module in Engine Systems

The 2880497 is an integral component in the aftertreatment system of modern engines. Its primary function is to facilitate the initial stages of exhaust gas treatment before the gases reach further downstream components such as the Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR) system.

Integration with Aftertreatment Device

When exhaust gases exit the engine, they first encounter the Inlet Catalyst Module. This module is designed to begin the reduction of Nitrogen Oxides (NOx) and other harmful emissions. The module works in conjunction with the aftertreatment device to ensure that the exhaust gases are treated effectively before being released into the atmosphere.

Synergy with Diesel Particulate Filter (DPF)

The Inlet Catalyst Module plays a supportive role in the operation of the DPF. By pre-treating the exhaust gases, it helps to reduce the load on the DPF, allowing it to operate more efficiently. This synergy ensures that particulate matter is captured more effectively, contributing to lower overall emissions.

Interaction with Selective Catalytic Reduction (SCR) System

In engines equipped with an SCR system, the Inlet Catalyst Module works in tandem to enhance the reduction of NOx. The pre-treated exhaust gases from the module enter the SCR system, where they interact with the injected urea solution. This interaction converts NOx into harmless nitrogen and water vapor, further reducing the environmental impact of the engine.

Contribution to Overall Emission Control

The 2880497 is a key player in the comprehensive emission control strategy of modern engines. By initiating the treatment process early in the exhaust stream, it sets the stage for the subsequent aftertreatment components to perform their functions more effectively. This integrated approach ensures that the engine meets stringent emission regulations while maintaining performance and efficiency.

Conclusion

The 2880497 Inlet Catalyst Module by Cummins is a critical component in the exhaust system of commercial trucks, designed to reduce harmful emissions and enhance engine performance. Its robust design, integration with aftertreatment devices, and contribution to overall emission control make it an essential part of modern engine systems. Regular maintenance and adherence to installation guidelines ensure its optimal performance and longevity.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Asef, P., Padmanaban, S., & Lapthorn, A. (2022). Modern Automotive Electrical Systems. Wiley.

↩ -

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.