This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 2880520 Inlet Catalyst Module is a component designed for use in heavy-duty trucks. It serves a specific function within the vehicle’s emissions control system, contributing to the reduction of harmful emissions released into the atmosphere. This module is integral to maintaining the truck’s performance while ensuring compliance with environmental regulations.

Basic Concepts of Inlet Catalyst Modules

An Inlet Catalyst Module is a device installed in the exhaust system of diesel engines. Its primary function is to reduce the levels of nitrogen oxides (NOx) and particulate matter (PM) emitted by the engine. The module achieves this by catalyzing chemical reactions that convert these pollutants into less harmful substances before they are released into the atmosphere. The effectiveness of an inlet catalyst module is vital for meeting stringent emissions standards and protecting the environment 1.

Purpose of the Cummins 2880520 Inlet Catalyst Module

The Cummins 2880520 Inlet Catalyst Module plays a role in the truck’s emissions control system by processing exhaust gases before they exit the vehicle. Positioned upstream in the exhaust stream, it interacts with other emissions control components, such as the Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR) system. This module helps in the early reduction of NOx, enhancing the overall efficiency of the emissions control process 2.

Key Features

The Cummins 2880520 Inlet Catalyst Module is characterized by its robust design and the use of high-quality materials that ensure durability and performance. It incorporates advanced catalytic technologies that facilitate efficient pollutant conversion. The module is engineered to withstand the high temperatures and pressures typical of diesel exhaust systems, ensuring long-term reliability.

Benefits of Using the Cummins 2880520 Inlet Catalyst Module

Incorporating the Cummins 2880520 Inlet Catalyst Module into a truck’s emissions control system offers several advantages. It contributes to improved emissions control, helping the vehicle meet or exceed environmental regulations. Additionally, by reducing the load on downstream emissions components, it may contribute to increased fuel efficiency. Compliance with environmental regulations is streamlined, reducing the risk of non-compliance penalties 3.

Installation and Integration

Proper installation of the Cummins 2880520 Inlet Catalyst Module is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure compatibility with the truck’s existing emissions control system. Considerations for installation include ensuring proper sealing to prevent exhaust leaks and verifying that the module is securely mounted to withstand vibrations and thermal expansion.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 2880520 Inlet Catalyst Module involves inspecting for signs of wear or damage, such as cracks or deterioration of the catalytic material. Diagnostic procedures may include monitoring exhaust gas temperatures and pressures to ensure the module is functioning within expected parameters. Common issues may include reduced efficiency due to catalyst poisoning or physical damage, which can be addressed through cleaning or replacement as necessary.

Performance and Efficiency

The Cummins 2880520 Inlet Catalyst Module contributes to the overall performance and efficiency of the truck by reducing the emissions load early in the exhaust process. This can lead to more efficient operation of downstream emissions control devices and potentially improve fuel economy. Studies and data have shown that well-maintained inlet catalyst modules can significantly reduce NOx emissions, demonstrating their effectiveness in emissions control strategies.

Environmental Impact

The use of the Cummins 2880520 Inlet Catalyst Module has a positive environmental impact by reducing the levels of harmful emissions released by heavy-duty trucks. By facilitating the conversion of NOx and PM into less harmful substances, it plays a part in mitigating air pollution and contributing to cleaner air quality. Compliance with environmental standards is enhanced, supporting global efforts to reduce the environmental footprint of transportation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to innovation and sustainability in the automotive and heavy-duty truck industries. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of modern transportation, emphasizing efficiency, reliability, and environmental responsibility.

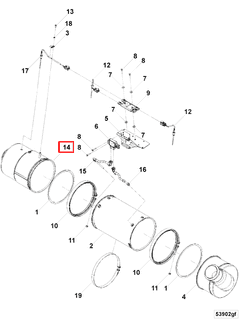

Role of Part 2880520 Inlet Catalyst Module in Aftertreatment Systems

The Part 2880520 Inlet Catalyst Module is an integral component within the aftertreatment system of modern engines. Its primary function is to facilitate the initial stages of exhaust gas treatment before the gases enter further downstream components.

Integration with Aftertreatment Devices

When exhaust gases exit the engine, they first encounter the Inlet Catalyst Module. This module is designed to begin the reduction of harmful emissions such as nitrogen oxides (NOx) and particulate matter (PM).

The module works in conjunction with other aftertreatment devices, such as:

-

Diesel Particulate Filters (DPFs): After passing through the Inlet Catalyst Module, the exhaust gases move into the DPF. Here, particulate matter is trapped and oxidized during periodic regeneration cycles.

-

Selective Catalytic Reduction (SCR) Systems: Following the DPF, the gases enter the SCR system where a reductant, typically diesel exhaust fluid (DEF), is injected. The Inlet Catalyst Module ensures that the exhaust gases are preconditioned, enhancing the efficiency of the SCR reaction.

-

NOx Sensors: Positioned both upstream and downstream of the Inlet Catalyst Module, these sensors monitor the levels of nitrogen oxides. The data from these sensors help the engine control unit (ECU) adjust the operation of the Inlet Catalyst Module and other aftertreatment components for optimal performance.

Operational Synergy

The Inlet Catalyst Module operates in harmony with these aftertreatment devices to ensure comprehensive emission control. By reducing the initial load of pollutants, it enhances the overall efficiency of the aftertreatment system. This synergy is essential for meeting stringent emission regulations and ensuring the engine operates within environmental standards.

Conclusion

The Cummins 2880520 Inlet Catalyst Module plays a significant role in the emissions control system of heavy-duty trucks. Its integration with other aftertreatment devices ensures efficient reduction of harmful emissions, contributing to environmental compliance and improved vehicle performance. Proper installation, maintenance, and understanding of its operation are crucial for maximizing the benefits of this Cummins part.

-

Asef, P., Padmanaban, S., & Lapthorn, A. (2022). Modern Automotive Electrical Systems. Wiley.

↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.