This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 2880555 Outlet Module is a component designed for use in commercial trucks. It serves a specific function within the truck’s system, contributing to the overall efficiency and performance of the vehicle. Understanding its purpose and operation is key to maintaining and optimizing the performance of commercial trucks.

Basic Concepts of Outlet Modules

An outlet module in a truck’s system is responsible for managing the flow of fluids, typically exhaust gases, from the engine to other parts of the system. It acts as a junction point, ensuring that the flow is directed correctly and efficiently. This module integrates with various components of the truck, including the engine and exhaust system, to maintain smooth operation and performance 1.

Purpose of the 2880555 Outlet Module

The Cummins 2880555 Outlet Module plays a role in the truck’s system by facilitating the efficient flow of exhaust gases. It is designed to work within the overall system to enhance the truck’s performance, ensuring that exhaust gases are managed effectively. This contributes to the truck’s overall efficiency and reliability 2.

Key Features

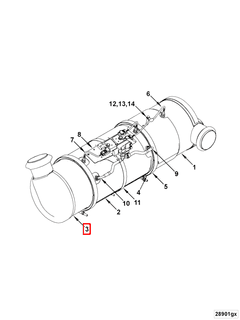

The 2880555 Outlet Module is characterized by several key features. Its design incorporates durable materials to withstand the harsh conditions of commercial truck operations. It includes precise engineering to ensure optimal flow management and integration with other system components. Unique characteristics may include specific connectors or mounting points that facilitate easy installation and maintenance 3.

Benefits

The use of the 2880555 Outlet Module in a truck’s system can lead to several benefits. These include improved efficiency in exhaust gas management, which can contribute to overall engine performance. The module’s reliable design ensures consistent operation, reducing the likelihood of system failures. Additionally, its integration into the truck’s system can enhance the vehicle’s performance, making it a valuable component for commercial truck operators 4.

Installation Process

Installing the 2880555 Outlet Module requires following a series of steps to ensure proper integration into the truck’s system. Prerequisites may include ensuring the truck’s system is compatible with the module and that all necessary tools are available. The installation process involves securing the module in place, connecting it to the appropriate system components, and verifying that it operates correctly within the system.

Troubleshooting Common Issues

Common issues with the 2880555 Outlet Module may include flow management problems or integration issues with other system components. Troubleshooting steps can involve checking the module’s connections, ensuring it is securely mounted, and verifying that it operates within the specified parameters. Addressing these issues promptly can help maintain the truck’s performance and efficiency.

Maintenance Tips

Regular maintenance of the 2880555 Outlet Module is important to ensure its longevity and optimal performance. This may include periodic inspections to check for wear or damage, cleaning the module to remove any buildup that could affect its operation, and verifying that all connections are secure. Following these maintenance practices can help prevent issues and ensure the module continues to operate effectively within the truck’s system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a key player in the commercial truck industry, providing innovative solutions that enhance the performance and efficiency of commercial vehicles.

Role of Part 2880555 Outlet Module in Engine Systems

The 2880555 Outlet Module is integral to the efficient operation of the aftertreatment device in engine systems. This component facilitates the controlled release of exhaust gases from the aftertreatment system, ensuring that emissions are managed effectively before they are expelled into the atmosphere.

In conjunction with the Diesel Particulate Filter (DPF), the Outlet Module helps maintain optimal backpressure levels, which is essential for the DPF’s regeneration process. This process burns off accumulated soot, keeping the filter clean and ensuring long-term efficiency.

Additionally, the Outlet Module interacts with the Selective Catalytic Reduction (SCR) system by allowing the precise flow of exhaust gases over the SCR catalyst. This interaction is vital for the conversion of nitrogen oxides (NOx) into harmless nitrogen and water vapor, adhering to stringent emission regulations.

The module also plays a role in the Exhaust Gas Recirculation (EGR) system by ensuring that recirculated exhaust gases are properly mixed with fresh intake air. This mixture helps reduce combustion temperatures, thereby lowering NOx formation.

Furthermore, the Outlet Module contributes to the overall durability and reliability of the engine system by withstanding high temperatures and pressures, which are common in aftertreatment processes. Its design ensures that it can handle the rigors of continuous operation without compromising performance.

Conclusion

The Cummins 2880555 Outlet Module is a critical component in the efficient operation of commercial trucks. Its role in managing exhaust gases, integrating with various engine systems, and contributing to emission control makes it an essential part of modern truck technology. Proper installation, maintenance, and understanding of its functions are vital for optimizing truck performance and ensuring compliance with emission regulations.

-

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning, 2011.

↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.