2885895

Decomposition Reactor

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 2885895 Decomposition Reactor, manufactured by Cummins, is a component designed to enhance the emissions control systems of heavy-duty trucks. Cummins, a well-established name in the automotive industry, has developed this reactor to address the growing need for more efficient and environmentally friendly emissions solutions. This reactor is significant in the context of heavy-duty truck emissions control, as it plays a role in reducing harmful emissions and ensuring compliance with stringent environmental regulations 1.

Basic Concepts of Decomposition Reactors

A decomposition reactor is a device that facilitates the breakdown of harmful emissions within an emissions control system. It operates by promoting chemical reactions that convert pollutants into less harmful substances. In the context of heavy-duty trucks, these reactors are integral to the after-treatment system, where they help in the reduction of nitrogen oxides (NOx) and particulate matter (PM). The chemical processes involved typically include selective catalytic reduction (SCR) and diesel particulate filtration (DPF), which work together to purify exhaust gases before they are released into the atmosphere 2.

Purpose of the 2885895 Decomposition Reactor

The 2885895 Decomposition Reactor is designed to play a specific role in the operation of a truck by reducing emissions. It is part of the after-treatment system that processes exhaust gases after they leave the engine. By facilitating the decomposition of harmful emissions, this reactor helps trucks meet environmental regulations and reduce their environmental impact. Its function is to ensure that the exhaust emitted by the truck is as clean as possible, thereby contributing to better air quality 3.

Key Features

The 2885895 Decomposition Reactor boasts several primary features that enhance its performance. Its design is optimized for efficient decomposition of emissions, utilizing advanced materials that are resistant to the high temperatures and corrosive environments found in exhaust systems. Unique technological aspects may include specialized catalysts that accelerate the chemical reactions necessary for emissions reduction. These features collectively contribute to the reactor’s effectiveness in purifying exhaust gases.

Benefits

The advantages provided by the 2885895 Decomposition Reactor include significant improvements in emissions reduction. By effectively breaking down pollutants, it helps trucks achieve lower emission levels, which is beneficial for environmental compliance. Additionally, there may be potential fuel efficiency gains associated with a well-functioning emissions control system, as optimized systems can contribute to overall engine performance. Compliance with regulatory standards is another key benefit, ensuring that trucks can operate within legal limits without incurring penalties.

Installation and Integration

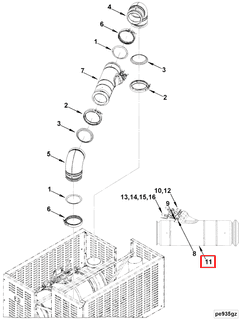

Installing the 2885895 Decomposition Reactor into a truck’s emissions control system requires careful consideration of several factors. Proper setup involves ensuring that the reactor is correctly positioned within the exhaust system to maximize its effectiveness. Prerequisites may include checking for compatibility with the truck’s engine and existing emissions control components. Integration should be performed by qualified technicians to ensure that all connections are secure and that the system operates as intended.

Operational Efficiency

The 2885895 Decomposition Reactor contributes to the overall efficiency of a truck’s emissions control system by ensuring that exhaust gases are thoroughly treated before being released. This can have a positive impact on engine performance, as a well-maintained emissions system can help prevent issues that might otherwise arise from untreated exhaust. Additionally, by reducing the amount of harmful emissions, the reactor can indirectly contribute to fuel efficiency, as a cleaner exhaust system can lead to smoother engine operation.

Troubleshooting and Maintenance

To ensure optimal performance and longevity of the 2885895 Decomposition Reactor, regular maintenance and troubleshooting are necessary. Common issues may include catalyst deactivation or blockages within the reactor. Diagnostic procedures should be followed to identify problems, which may involve checking for proper flow through the reactor and assessing the condition of the catalyst. Maintenance practices include regular inspections and cleaning, as well as replacing components as needed to maintain efficiency.

Regulatory Compliance

The 2885895 Decomposition Reactor plays a role in helping trucks meet emissions regulations by ensuring that exhaust gases are treated to reduce pollutants to acceptable levels. Relevant standards may include those set by environmental protection agencies, which dictate the maximum allowable emissions for heavy-duty trucks. Testing procedures are in place to verify compliance, and the reactor is designed to assist trucks in passing these tests, thereby ensuring they can operate within legal limits.

Cummins Overview

Cummins is a manufacturer with a rich history in the automotive industry, particularly in engine and emissions technology. The company is known for its expertise in developing innovative solutions that enhance engine performance while reducing environmental impact. Cummins’ commitment to sustainability is evident in its ongoing efforts to develop advanced emissions control technologies, including the 2885895 Decomposition Reactor. This commitment underscores Cummins’ role as a leader in the industry, dedicated to providing high-quality, reliable components that meet the needs of modern heavy-duty trucks 4.

Compatibility

The Cummins Decomposition Reactor part number 2885895 is designed to enhance the performance and efficiency of several Cummins engine models. This part is engineered to work seamlessly with a range of Cummins engines, ensuring optimal operation and reliability.

ISB6.7 Series

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

The ISB6.7 series engines benefit significantly from the integration of the Decomposition Reactor. This part helps in reducing emissions and improving fuel efficiency, making it an essential component for these models.

ISC8.3 Series

- ISC8.3 CM2250

The ISC8.3 engine, when equipped with the Decomposition Reactor, experiences enhanced combustion processes, leading to better performance and reduced environmental impact.

ISL9 Series

- ISL9 CM2250

For the ISL9 engine, the Decomposition Reactor plays a crucial role in maintaining the balance between power output and emissions control, ensuring the engine operates at peak efficiency.

ISX12 Series

- ISX12 CM2350 X102

- ISX12/ISX11.9 CM2250

The ISX12 series engines, including the ISX12 CM2350 X102 and the ISX12/ISX11.9 CM2250, are designed to handle high workloads. The Decomposition Reactor is integral to managing the complex combustion processes in these engines, ensuring they deliver consistent power while minimizing emissions.

ISX15 Series

- ISX15 CM2250

- ISX15 CM2350 X101

- X15 CM2350 X116B

The ISX15 series engines, such as the ISX15 CM2250, ISX15 CM2350 X101, and X15 CM2350 X116B, are among the most powerful in Cummins’ lineup. The Decomposition Reactor is essential for these engines, providing the necessary support for high-performance operations while maintaining stringent emission standards.

Role of Part 2885895 Decomposition Reactor in Engine Systems

The Decomposition Reactor, identified as part 2885895, is an integral component within the aftertreatment system of modern engine designs. Its primary function is to facilitate the breakdown of specific compounds within the exhaust stream, enhancing the overall efficiency and environmental compliance of the engine.

When integrated into the aftertreatment system, the Decomposition Reactor works in conjunction with the Doser and Fluid Doser. The Doser injects a precise amount of fluid into the exhaust stream, which is then directed towards the Decomposition Reactor. This fluid, often a urea-based solution, plays a vital role in the Selective Catalytic Reduction (SCR) process.

As the exhaust gases pass through the Decomposition Reactor, the injected fluid decomposes into ammonia and carbon dioxide. This decomposition is essential for the subsequent reduction of nitrogen oxides (NOx) into nitrogen and water vapor, which are less harmful to the environment.

The effectiveness of the Decomposition Reactor is highly dependent on the proper functioning of the Fluid Doser and the overall plumbing system that delivers the fluid to the reactor. Any discrepancies in fluid delivery can lead to inefficient decomposition and, consequently, reduced effectiveness of the aftertreatment system.

Conclusion

In summary, the Decomposition Reactor (part 2885895) is a key player in the aftertreatment process, ensuring that the exhaust emitted from the engine meets stringent environmental standards. Its interaction with the Doser, Fluid Doser, and the exhaust system underscores the importance of a well-maintained and properly functioning aftertreatment system.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Naunheimer, Harald, et al. Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg, 2011.

↩ -

Pulkrabek, Willard W. Engineering Fundamentals of the Internal Combustion Engine. Pearson Education, 2014.

↩ -

Sclar, Deanna. Auto Repair for Dummies: 2nd Edition. For Dummies, 2008.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.