2897691

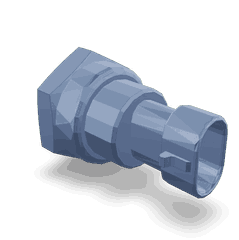

Pressure Switch

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 2897691 Pressure Switch is a component designed for use in commercial trucks. Its purpose is to monitor and regulate pressure within specific systems of the vehicle, ensuring optimal performance and safety. This switch is integral to maintaining the efficiency and reliability of truck operations, particularly in environments where precise pressure control is necessary.

Basic Concepts of Pressure Switches

A pressure switch is a device that opens or closes an electrical circuit in response to a specific pressure threshold. It operates by using a diaphragm or piston that moves in response to changes in pressure, activating a switch mechanism. Pressure switches are commonly used in various systems, including hydraulic, pneumatic, and fuel systems, to control operations based on pressure conditions 1.

Function of the 2897691 Pressure Switch

The Cummins 2897691 Pressure Switch plays a specific role in the operation of a truck by monitoring pressure levels within designated systems. It is integrated into the truck’s systems to ensure that pressure remains within safe and operational limits. The switch activates or deactivates circuits based on the pressure it detects, which helps in maintaining system integrity and preventing damage from over or under-pressurization 2.

Key Features

The Cummins 2897691 Pressure Switch is characterized by its robust design and the use of high-quality materials, which contribute to its durability and reliability. It features a precise pressure sensing mechanism that ensures accurate readings and timely responses to pressure changes. Additionally, the switch is designed to withstand the harsh conditions typical of commercial truck environments, enhancing its performance and longevity.

Benefits

The advantages provided by the Cummins 2897691 Pressure Switch include improved system efficiency and reliability. By accurately monitoring and regulating pressure, it helps prevent system failures and enhances the overall performance of the truck. Furthermore, the switch contributes to safety by ensuring that systems operate within safe pressure limits, reducing the risk of accidents related to pressure issues 3.

Troubleshooting and Maintenance

Common issues that may arise with the Cummins 2897691 Pressure Switch include inaccurate pressure readings or failure to activate under the correct conditions. Diagnosing problems may involve checking the switch for physical damage, ensuring it is correctly installed, and verifying that the pressure system it monitors is functioning as intended. Regular maintenance, such as cleaning the switch and inspecting its connections, can help ensure longevity and optimal performance.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a key player in the commercial truck industry, known for its commitment to quality, innovation, and customer satisfaction. The company’s products are designed to meet the demanding requirements of commercial applications, ensuring reliability and performance in various operating conditions.

Cummins Pressure Switch 2897691 Compatibility

The Cummins Pressure Switch 2897691 is designed to monitor and regulate the pressure within various engine systems. This switch is compatible with a range of Cummins engines, ensuring reliable operation across multiple models. Below is a detailed description of its compatibility with specific engine types:

Cummins 4B3.9 and QSB3.9 30 CM550 Engines

The Pressure Switch 2897691 is engineered to fit seamlessly with the Cummins 4B3.9 and QSB3.9 30 CM550 engines. These engines are known for their robust performance and are commonly used in various applications, including agricultural and industrial machinery. The switch’s precise pressure monitoring capabilities help maintain optimal engine performance and prevent potential damage due to pressure fluctuations.

Cummins 6B5.9 and QSB5.9 30 CM550 Engines

Similarly, the Pressure Switch 2897691 is compatible with the Cummins 6B5.9 and QSB5.9 30 CM550 engines. These engines are part of the Cummins QSB series, which is renowned for its durability and efficiency. The switch ensures that the pressure within these engines remains within safe limits, contributing to the longevity and reliability of the engine.

Cummins B3.3, B4.5, and QSB4.5 CM850 (CM2850) Engines

The Pressure Switch 2897691 also fits the Cummins B3.3, B4.5, and QSB4.5 CM850 (CM2850) engines. These engines are designed for applications requiring moderate power and efficiency. The switch’s integration into these engines helps maintain consistent pressure levels, ensuring smooth operation and reducing the risk of pressure-related issues.

Cummins M11 CELECT PLUS and M11 MECHANICAL Engines

For the Cummins M11 CELECT PLUS and M11 MECHANICAL engines, the Pressure Switch 2897691 is an essential component. These engines are known for their high performance and are used in heavy-duty applications. The switch’s role in monitoring and regulating pressure is crucial for maintaining the engine’s efficiency and preventing potential failures.

Cummins N14 G and N14 MECHANICAL Engines

The Pressure Switch 2897691 is also compatible with the Cummins N14 G and N14 MECHANICAL engines. These engines are designed for heavy-duty applications and are known for their power and reliability. The switch ensures that the pressure within these engines is maintained at optimal levels, contributing to their overall performance and durability.

Cummins NH/NT 855 Engines

The Pressure Switch 2897691 fits the Cummins NH/NT 855 engines, which are commonly used in agricultural machinery. The switch’s precise pressure monitoring capabilities help ensure that these engines operate efficiently and reliably, even under demanding conditions.

Cummins QSM11 CM570 and QST30 CM552 Engines

The Pressure Switch 2897691 is also compatible with the Cummins QSM11 CM570 and QST30 CM552 engines. These engines are part of the Cummins QSM and QST series, which are designed for a variety of applications. The switch’s role in maintaining pressure levels is essential for the smooth operation and longevity of these engines.

Cummins K19, K38, and K50 Engines

The Pressure Switch 2897691 is also suitable for the Cummins K19, K38, and K50 engines. These engines are known for their versatility and are used in various applications, including construction and industrial machinery. The switch ensures that the pressure within these engines remains within safe limits, contributing to their reliable performance.

Cummins V28 Engine

Lastly, the Pressure Switch 2897691 fits the Cummins V28 engine. This engine is designed for high-performance applications and is known for its power and efficiency. The switch’s role in monitoring and regulating pressure is crucial for maintaining the engine’s performance and preventing potential issues.

This comprehensive compatibility ensures that the Cummins Pressure Switch 2897691 is a versatile and essential component for maintaining the performance and reliability of a wide range of Cummins engines.

Role of Part 2897691 Pressure Switch in Engine Systems

The Part 2897691 Pressure Switch is an integral component in various engine systems, ensuring optimal performance and safety. Its primary function is to monitor and regulate pressure within the system, providing essential data and triggering necessary actions when pressure levels deviate from the desired range.

Integration with Engine Systems

-

Aftercooler Plumbing: The Pressure Switch is often integrated into the aftercooler plumbing system. It monitors the pressure of the cooled air, ensuring it remains within specified limits to maintain engine efficiency and prevent damage.

-

Control and Safety Systems: Within control and safety systems, the Pressure Switch acts as a safeguard. It detects abnormal pressure conditions and signals the control system to take corrective actions, such as adjusting the engine parameters or activating safety protocols.

-

Signal Generating Devices: The Pressure Switch generates electrical signals corresponding to the pressure levels it detects. These signals are crucial for the engine’s instrumentation and control systems to make informed decisions.

-

Electrical Mounting and Engine Installation Kit: When installed as part of an electrical mounting or engine installation kit, the Pressure Switch ensures that all pressure-sensitive components are correctly monitored and controlled from the onset of engine operation.

-

Engine Instrumentation: Incorporated into engine instrumentation, the Pressure Switch provides real-time data on pressure conditions. This data is displayed on gauges and safety controls, allowing operators to monitor the engine’s health and performance continuously.

-

Engine Mounting Parts Kit: In an engine mounting parts kit, the Pressure Switch helps in maintaining the integrity of the engine’s pressure systems during installation and operation, ensuring that all components are functioning within safe pressure limits.

-

Gauges and Safety Control: The Pressure Switch works in tandem with gauges and safety controls to provide a comprehensive overview of the engine’s pressure conditions. This integration ensures that any deviations are quickly identified and addressed.

-

Instrumentation Kit: As part of an instrumentation kit, the Pressure Switch contributes to a holistic monitoring system. It ensures that all pressure-related data is accurately captured and relayed to the engine’s control systems.

-

Kit On Board Spares and Kit Spares: Included in on-board spares and kit spares, the Pressure Switch offers a reliable backup for maintaining engine pressure monitoring capabilities, even in the event of component failure.

-

Railcar Installation and Panel Engine Instrument: In railcar installations, the Pressure Switch is vital for ensuring that the engine’s pressure systems are consistently monitored. It is often mounted on the panel alongside other engine instruments to provide a centralized monitoring solution.

-

Safety Control and Sensor: The Pressure Switch interacts with safety controls and sensors to create a robust safety net. It ensures that the engine operates within safe pressure parameters, triggering alerts or shutdowns when necessary.

-

Oil Pressure Switch: Specifically, when used as an oil pressure switch, it monitors the pressure of the engine’s lubrication system. This ensures that the engine receives adequate lubrication, preventing wear and damage.

-

Engine Monitoring System: Finally, the Pressure Switch is a key component in the engine monitoring system. It provides continuous pressure data, enabling comprehensive engine health assessments and facilitating proactive maintenance strategies.

Conclusion

The Cummins 2897691 Pressure Switch is a critical component in the operation and maintenance of commercial trucks and various Cummins engines. Its role in monitoring and regulating pressure ensures optimal performance, safety, and reliability. By integrating this part into engine systems, it contributes to the overall efficiency and longevity of the vehicle, making it an indispensable element in the realm of commercial trucking and engine technology.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.