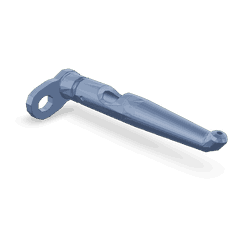

3007517

Piston Cooling Nozzle

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3007517 Piston Cooling Nozzle is a component designed to enhance the operation of heavy-duty truck engines. Its purpose is to manage the temperature of the piston by directing a stream of oil onto its underside. This process helps maintain optimal engine performance and longevity by mitigating thermal stress 1.

Basic Concepts of Piston Cooling Nozzles

A piston cooling nozzle is a device that sprays oil onto the underside of a piston to cool it. Within an engine, this nozzle operates by utilizing engine oil pressure to atomize oil into fine droplets. These droplets then contact the piston’s surface, absorbing heat and subsequently cooling it. The principles behind its operation involve thermodynamics and fluid dynamics, ensuring efficient heat transfer from the piston to the oil 2.

Purpose of the 3007517 Piston Cooling Nozzle

The 3007517 Piston Cooling Nozzle plays a role in the operation of a truck engine by managing the temperature of the piston. This management contributes to engine performance by ensuring that the piston operates within its optimal temperature range. Additionally, it aids in prolonging the engine’s lifespan by reducing thermal stress on the piston, which can lead to deformation or failure if not properly managed 3.

Key Features

The 3007517 is characterized by its precise design, which ensures an effective spray pattern for optimal cooling. It is constructed from durable materials that can withstand the high temperatures and pressures within an engine. Unique attributes include its ability to atomize oil efficiently, enhancing its cooling capabilities.

Benefits

The benefits provided by the 3007517 include improved engine efficiency through better temperature management of the piston. It also reduces thermal stress on the piston, which can lead to enhanced engine reliability and performance. Additionally, by maintaining optimal piston temperature, the nozzle contributes to the overall longevity of the engine.

Installation and Integration

For the proper installation and integration of the 3007517 within a truck engine, it is important to follow manufacturer guidelines. This may involve preparations such as ensuring the engine is clean and free of debris, and making any necessary adjustments to accommodate the nozzle. Proper installation is key to ensuring the nozzle functions as intended.

Troubleshooting Common Issues

Common issues that may arise with the 3007517 include blockages in the oil passage or wear on the nozzle itself. Troubleshooting steps may involve inspecting the nozzle for signs of damage or blockage and cleaning or replacing it as necessary. Regular maintenance can help prevent many of these issues.

Maintenance Tips

Regular maintenance of the 3007517 is important for ensuring optimal performance and longevity. This includes periodic inspection for signs of wear or damage, and cleaning the nozzle to remove any buildup that may impede its function. Following these maintenance tips can help ensure the nozzle continues to operate effectively.

Performance Enhancements

Potential performance enhancements or modifications to the 3007517 may include upgrading to a nozzle with a more efficient spray pattern or using higher-quality materials for increased durability. These modifications can further improve engine efficiency and reliability by enhancing the cooling capabilities of the nozzle.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry. Its product offerings include a wide range of engines and components designed for heavy-duty applications, demonstrating a commitment to excellence and customer satisfaction.

Integration of Piston Cooling Nozzle (Part 3007517) in Engine Systems

The Piston Cooling Nozzle (Part 3007517) is an integral component in the thermal management of engine systems, particularly in high-performance and heavy-duty applications. Its role is to direct a stream of coolant onto the underside of the piston, effectively managing the temperature and enhancing the longevity and efficiency of the engine.

Interaction with Key Engine Components

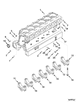

Cylinder Block and Short Block Assemblies

In the cylinder block, especially within short block assemblies like the KTTA-19C Short Block or the Cylinder Short K-6 Block, the Piston Cooling Nozzle is strategically positioned. It ensures that the piston, a component subjected to extreme temperatures due to combustion, remains within optimal operating temperatures. This is vital for maintaining the structural integrity of the piston and the overall efficiency of the engine.

Cylinder Head and Cylinder Kit Block

The nozzle works in conjunction with the cylinder head and the cylinder kit block to create a balanced thermal environment. By cooling the piston, it indirectly aids in the efficient operation of the cylinder head, which houses the valves and spark plugs. This balance is essential for the precise timing and efficiency of the combustion process.

Connecting Rod and Piston Assembly

Within the connecting rod and piston assembly, the cooling nozzle plays a supportive role. It helps in reducing thermal expansion of the piston, which can lead to increased clearances and potential mechanical issues. This ensures that the connecting rod operates within its designed parameters, contributing to smoother engine operation and reduced wear.

Camshaft and Valve Train

Although not directly interacting, the efficient operation of the Piston Cooling Nozzle indirectly benefits the camshaft and valve train. By maintaining optimal piston temperatures, it ensures consistent engine performance, which is crucial for the timing and operation of the valve train components.

Injector and Fuel System

In engines where fuel injection is employed, the cooling nozzle’s role becomes even more significant. It helps in maintaining a stable environment for the injector to operate, ensuring precise fuel delivery and combustion. This is particularly important in high-performance engines where fuel efficiency and power output are paramount.

Role in Overhaul and Performance Kits

In overhaul kits and performance parts, the inclusion of the Piston Cooling Nozzle is a testament to its importance in engine maintenance and upgrade. It is often part of a comprehensive approach to engine rebuilding or performance enhancement, ensuring that all aspects of engine operation, including thermal management, are addressed.

Service and Tool Integration

For service and maintenance, tools designed for the installation and removal of the Piston Cooling Nozzle are essential. These tools ensure that the nozzle is correctly positioned and functioning, which is critical for the ongoing health and performance of the engine.

Conclusion

In summary, the Piston Cooling Nozzle (Part 3007517) is a key player in the thermal management of engine systems. Its interaction with various engine components, from the cylinder block to the fuel injection system, underscores its importance in maintaining engine efficiency, performance, and longevity.

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| O Ring Seal | 1 | 3015067 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.