This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

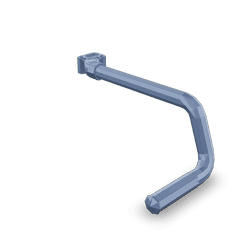

The Lubricating Oil Suction Tube 3011046 is a component designed by Cummins for use in commercial trucks. Its purpose is to facilitate the efficient suction of lubricating oil from the oil pan to the engine’s lubrication system. This part ensures that engine components receive the necessary lubrication for smooth operation and longevity 1.

Function and Operation

The Lubricating Oil Suction Tube operates within the engine’s lubrication system by drawing oil from the oil pan and directing it towards the oil pump. This process is vital for maintaining a consistent flow of lubricant to critical engine components, such as bearings, pistons, and camshafts. Proper lubrication reduces friction, minimizes wear, and helps in dissipating heat, thereby contributing to the overall efficiency and durability of the engine 2.

Key Features

The Lubricating Oil Suction Tube 3011046 is constructed from high-quality materials that ensure durability and resistance to the harsh conditions within an engine environment. Its design includes precise engineering to optimize oil flow and reduce the risk of blockages. The tube is also designed to withstand high temperatures and pressures, ensuring reliable performance over the vehicle’s operational life 3.

Benefits

Incorporating the Lubricating Oil Suction Tube 3011046 into an engine’s lubrication system offers several advantages. It enhances the efficiency of oil circulation, which leads to improved lubrication of engine components. This can result in extended component lifespan and enhanced overall engine performance. Additionally, the design of the tube contributes to maintaining optimal oil levels within the engine, further supporting its reliable operation 4.

Installation and Compatibility

When installing the Lubricating Oil Suction Tube 3011046, it is important to follow manufacturer guidelines to ensure proper fit and function. Specific requirements may vary depending on the truck model and engine type. Careful attention to alignment and securement is necessary to prevent leaks and ensure efficient oil suction 5.

Maintenance and Care

Routine maintenance of the Lubricating Oil Suction Tube 3011046 is crucial for ensuring optimal performance and longevity. Regular inspections should be conducted to check for signs of wear, leaks, or blockages. Cleaning the tube as part of regular oil change procedures can help prevent the accumulation of contaminants that could impede oil flow 6.

Troubleshooting Common Issues

Common issues associated with the Lubricating Oil Suction Tube 3011046 may include leaks or blockages. Troubleshooting these problems involves inspecting the tube for damage, ensuring proper installation, and cleaning or replacing the tube if necessary. Addressing these issues promptly can help maintain the efficiency of the engine’s lubrication system 7.

Safety Considerations

When working with the Lubricating Oil Suction Tube 3011046, it is important to follow safety precautions to prevent accidents or injuries. This includes wearing appropriate personal protective equipment, ensuring the engine is cool before beginning work, and following proper handling, installation, and maintenance procedures 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s product offerings include a wide range of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles 9.

Cummins Lubricating Oil Suction Tube (Part 3011046) Compatibility

The Cummins Lubricating Oil Suction Tube, identified by part number 3011046, is a critical component in the engine’s lubrication system. This part ensures that oil is efficiently and consistently drawn from the oil pan to the oil pump, maintaining the necessary lubrication for engine components.

K19 Engine Series

The K19 engine series is designed for heavy-duty applications, providing robust performance and reliability. The 3011046 Lubricating Oil Suction Tube is specifically engineered to fit seamlessly within the K19 engine’s architecture. This compatibility ensures optimal oil flow, which is crucial for maintaining engine health and longevity.

The K19 engine series includes various models, all of which benefit from the precise fit and function of the 3011046 part. This ensures that regardless of the specific K19 model, the lubrication system operates efficiently, reducing wear and tear on engine components.

Grouping of Compatible Engines

The 3011046 Lubricating Oil Suction Tube is not limited to the K19 series alone. Cummins has designed this part to be compatible with a range of their heavy-duty engines, ensuring a standardized approach to engine lubrication. This compatibility extends to other engine series within Cummins’ lineup, providing a reliable and efficient solution across multiple engine models.

By using the 3011046 part, engine manufacturers and operators can be assured of a consistent and dependable lubrication system, which is essential for the performance and durability of the engines 10.

Role of Part 3011046 Lubricating Oil Suction Tube in Engine Systems

The lubricating oil suction tube, identified by part number 3011046, is integral to the efficient operation of engine systems. This component is responsible for drawing oil from the oil pan, ensuring a consistent supply of lubricant to the engine’s moving parts.

Integration with the Oil Pan

The oil pan serves as the reservoir for the engine’s lubricant. Positioned at the bottom of the engine, it collects and stores the oil used to lubricate various components. The lubricating oil suction tube connects directly to the oil pan, facilitating the extraction of oil. This tube ensures that oil is efficiently drawn from the pan and directed towards the oil pump. The consistent flow of oil from the pan to the pump is essential for maintaining the engine’s lubrication system 11.

Ensuring Steady Oil Supply

As the suction tube draws oil from the pan, it plays a key role in maintaining a steady supply of lubricant. This is particularly important during engine operation, where consistent lubrication prevents excessive wear and tear on engine components. The tube’s design and placement within the engine system allow it to effectively manage the flow of oil, contributing to the overall efficiency and longevity of the engine 12.

Supporting Engine Performance

By ensuring a reliable oil supply, the lubricating oil suction tube supports the engine’s performance. Proper lubrication reduces friction between moving parts, which in turn helps in maintaining optimal engine temperature and efficiency. The tube’s function is seamless yet vital, as it works in conjunction with other components to uphold the engine’s operational standards 13.

Conclusion

Understanding the role of the lubricating oil suction tube within the engine system highlights its importance in maintaining engine health and performance. Its integration with the oil pan and contribution to a steady oil supply are fundamental to the engine’s lubrication process 14.

-

Limpert, Rudolf. Brake Design and Safety, Third Edition. SAE International, 2011.

↩ -

Rendle, Steve, and Martynn Randall. Haynes Diesel Engine Systems and Data Book. Haynes Publishing, 2000.

↩ -

Robinson, Alan, and Andrew Livesey. The Repair of Vehicle Bodies Fifth Edition. Elsevier, 2006.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388674, QSL9 CM2350 L118.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388674, QSL9 CM2350 L118.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388674, QSL9 CM2350 L118.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388674, QSL9 CM2350 L118.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388674, QSL9 CM2350 L118.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388674, QSL9 CM2350 L118.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388674, QSL9 CM2350 L118.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388674, QSL9 CM2350 L118.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388674, QSL9 CM2350 L118.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388674, QSL9 CM2350 L118.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4388674, QSL9 CM2350 L118.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.