This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Bleed Tube 3015375 is a component manufactured by Cummins, a prominent entity in the automotive industry, especially in commercial truck operations. This part is designed to maintain the efficiency and reliability of truck hydraulic and fuel systems. Its role is integral to the overall performance of these systems, ensuring that commercial trucks operate smoothly and effectively.

Purpose and Function

The Bleed Tube 3015375 serves a specific purpose within the truck’s hydraulic and fuel systems. It facilitates the removal of air from these systems, which is essential for their efficient operation. When air is present in hydraulic or fuel lines, it can lead to inefficiencies, such as reduced pressure and compromised system performance. This part allows for the controlled release of air, ensuring that the systems operate under optimal conditions. This function is particularly important during the initial setup of the system or after maintenance work that may have introduced air into the lines 1.

Key Features

The Bleed Tube 3015375 is characterized by several key features that enhance its performance and durability. Its design is tailored to effectively manage the removal of air from the system. The materials used in its construction are chosen for their durability and resistance to the pressures and temperatures encountered in truck hydraulic and fuel systems. Additionally, the bleed tube may feature unique characteristics, such as a specific thread size or connection type, that ensure a secure and leak-free fit within the system 2.

Benefits

Utilizing the Bleed Tube 3015375 offers several benefits. It contributes to improved system efficiency by ensuring that air does not interfere with the operation of the hydraulic or fuel systems. This leads to more reliable truck operations, as the systems are able to perform as intended without the disruptions that air can cause. Furthermore, the use of a high-quality bleed tube can reduce maintenance needs, as it is less likely to fail or require replacement. This not only saves time but also reduces the overall cost of maintaining the truck 3.

Installation and Usage

Proper installation and usage of the Bleed Tube 3015375 are crucial for its effective operation. Before installation, it is important to ensure that the system is clean and free of any debris that could interfere with the bleed tube’s function. The installation process may require specific tools, depending on the design of the bleed tube and the system it is being installed in. Once installed, operational checks should be performed to ensure that the bleed tube is functioning correctly and that air is being effectively removed from the system.

Troubleshooting and Maintenance

Common issues with the Bleed Tube 3015375 may include leaks or failure to remove air effectively. Troubleshooting these issues may involve checking the connections for tightness and ensuring that the bleed tube is correctly installed. Regular maintenance, such as inspecting the bleed tube for signs of wear or damage, can help prolong its lifespan and ensure optimal performance. It is also important to follow the manufacturer’s guidelines for maintenance and replacement to keep the system running efficiently.

Safety Considerations

When working with the Bleed Tube 3015375, it is important to observe safety precautions. This includes wearing appropriate personal protective equipment (PPE) and ensuring that the system is depressurized before beginning any work. Operational safety measures, such as regularly checking the system for leaks or signs of wear, can help prevent accidents. In the event of a malfunction, emergency procedures should be followed to safely address the issue and prevent further damage.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the automotive industry. Its product range is designed to meet the demanding requirements of commercial truck operations, ensuring reliability, efficiency, and performance.

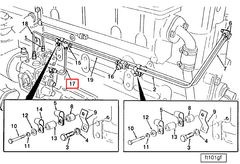

Bleed Tube Part 3015375 in Cummins Engines

This Cummins part is a critical component in the engine systems of the N14 MECHANICAL and NH/NT 855 engines. This part is integral to the engine’s operation, ensuring that the fuel system functions correctly by allowing the release of air and fuel vapors.

In the N14 MECHANICAL engine, 3015375 is designed to fit seamlessly within the engine’s architecture, facilitating the proper flow of fuel and air. This ensures that the engine maintains optimal performance and efficiency. Similarly, in the NH/NT 855 engine, the Bleed Tube is engineered to integrate with the engine’s design, providing a reliable method for managing fuel and air pressures.

This part is a testament to Cummins’ commitment to quality and precision, ensuring that it meets the stringent demands of both the N14 MECHANICAL and NH/NT 855 engines. Its compatibility with these engines underscores its importance in maintaining the overall health and performance of the engine systems.

Role of Part 3015375 Bleed Tube in Engine Systems

The Bleed Tube is an integral component in the efficient operation of various engine systems. It is specifically designed to manage the flow and pressure of fuel within the engine, ensuring optimal performance and safety.

Fuel Bypass System Integration

In the fuel bypass system, the Bleed Tube works in conjunction with the fuel bypass mounting and fuel bypass tube. Its primary function here is to regulate the excess fuel that bypasses the main fuel line. This regulation is vital for maintaining consistent fuel pressure and preventing potential fuel leaks or system overloads.

Fuel Line Return and Plumbing

Within the fuel line return system, the Bleed Tube plays a significant role. It is integrated into the fuel plumbing to facilitate the return of unused fuel from the engine back to the fuel tank. This process is essential for maintaining the correct fuel pressure and ensuring that the fuel system operates within its designed parameters.

Fuel Pump and Fuel Tubing

The interaction between the Bleed Tube and the fuel pump is noteworthy. The Bleed Tube assists in managing the pressure exerted by the fuel pump on the fuel tubing. By doing so, it helps in preventing excessive pressure build-up, which could lead to fuel line failures or inefficiencies in fuel delivery.

Overall Fuel System Harmony

In the broader context of the fuel system, the Bleed Tube contributes to the overall harmony and efficiency of fuel delivery and management. It ensures that the fuel system operates smoothly, with the right balance of pressure and flow, which is essential for the engine’s performance and longevity.

Mounting and By-Pass Tubes

The Bleed Tube is also a key component in the mounting and fuel bypass tube assemblies. It aids in the secure and efficient mounting of these tubes, ensuring that they are properly aligned and functioning as intended within the engine’s fuel system.

Conclusion

In summary, the Bleed Tube is a vital element in various components of the engine’s fuel system, playing a significant role in maintaining the system’s integrity, efficiency, and safety.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.