This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

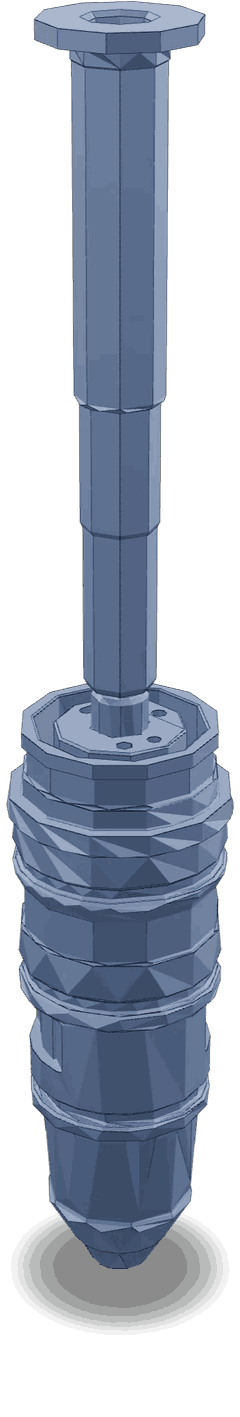

The Cummins 3016676 Fuel Injector is a component designed for use in commercial trucks, playing a significant role in the efficient operation of diesel engines. This injector is part of Cummins’ lineup of fuel delivery systems, which are engineered to enhance engine performance, fuel efficiency, and emissions control. Understanding the function and importance of this Cummins part provides insight into its contribution to the overall operation and maintenance of commercial trucks.

Basic Concepts of Fuel Injectors

A fuel injector is a device that delivers fuel into an engine’s combustion chamber. It operates by atomizing fuel into a fine mist, which mixes with air for combustion. The principles of fuel injection technology involve precise control over the timing, quantity, and pressure of fuel delivery to optimize engine performance and efficiency 1. Fuel injectors are a key component in modern diesel engines, contributing to better fuel economy, reduced emissions, and enhanced power output.

Role of the 3016676 Fuel Injector in Truck Operation

The Cummins 3016676 Fuel Injector plays a specific role in the combustion process by delivering fuel into the engine’s cylinders at precise moments and in exact quantities. This ensures optimal air-fuel mixture for combustion, which is crucial for engine performance. The injector’s design allows for efficient fuel atomization, which facilitates complete combustion and contributes to the engine’s overall efficiency and power output 2.

Key Features of the 3016676 Fuel Injector

The 3016676 Fuel Injector is characterized by several key features, including its robust design, the use of high-quality materials, and technological advancements. It is engineered to withstand the high pressures and temperatures of diesel engine operation. The injector incorporates precision-machined components and advanced sealing technologies to ensure reliable performance and durability. Additionally, it features electronic controls that allow for fine-tuning of fuel delivery parameters.

Benefits of Using the 3016676 Fuel Injector

The use of the 3016676 Fuel Injector offers several advantages. It contributes to improved fuel efficiency by ensuring precise fuel delivery, which reduces waste and enhances combustion efficiency. The injector also supports enhanced engine performance through optimal fuel atomization and combustion. Furthermore, it aids in reducing emissions by promoting cleaner and more complete combustion, which is beneficial for environmental compliance and air quality 3.

Maintenance and Troubleshooting

Routine maintenance of the 3016676 Fuel Injector involves regular inspection and cleaning to ensure optimal performance. Common issues that may arise include clogging, leaks, or malfunctions in the electronic control system. Troubleshooting steps may include cleaning the injector, checking for leaks, and verifying the integrity of the electronic connections. Regular maintenance and prompt addressing of issues help maintain the injector’s efficiency and longevity.

Integration with Engine Management Systems

The 3016676 Fuel Injector is designed to integrate seamlessly with modern engine management systems. This integration allows for dynamic adjustment of fuel delivery parameters based on engine load, speed, and other operating conditions. The injector’s electronic controls work in conjunction with the engine management system to optimize performance, efficiency, and emissions control in real-time.

Environmental Impact

The use of the 3016676 Fuel Injector contributes to environmental benefits by enabling more efficient and cleaner combustion. This results in reduced emissions of harmful pollutants, such as nitrogen oxides (NOx) and particulate matter (PM), which are significant contributors to air pollution. The injector’s role in promoting cleaner combustion supports efforts to improve air quality and comply with environmental regulations.

Technological Innovations

The Cummins 3016676 Fuel Injector incorporates several technological innovations. These include advanced materials for durability, precision machining for accurate fuel delivery, and electronic controls for dynamic performance optimization. The integration of these technologies enhances the injector’s reliability, efficiency, and compatibility with modern engine management systems.

Cummins Corporation

Cummins Corporation is a leading manufacturer of diesel engines, with a reputation for innovation and quality in the automotive and heavy-duty truck industries. The company is committed to developing advanced technologies that improve engine performance, fuel efficiency, and emissions control. Cummins’ expertise in fuel injection systems is demonstrated through the design and manufacturing of the 3016676 Fuel Injector, which embodies the company’s dedication to excellence and environmental responsibility.

Compatibility with Cummins Engines

The Cummins Fuel Injector part number 3016676 is designed to be compatible with a range of Cummins engines, ensuring precise fuel delivery and optimal engine performance. This injector is engineered to meet the stringent requirements of various engine models, providing reliability and efficiency.

K19 Engines

For the K19 engines, the 3016676 fuel injector is a critical component that ensures the engine operates smoothly. This injector is specifically calibrated to deliver the correct amount of fuel at the right pressure and timing, which is essential for the K19’s performance and longevity.

K38 Engines

The K38 engines also benefit from the 3016676 fuel injector. This part is engineered to handle the specific demands of the K38, ensuring that fuel is injected with precision. The compatibility of this injector with the K38 engine helps maintain the engine’s efficiency and power output.

K50 Engines

Similarly, the K50 engines are designed to work seamlessly with the 3016676 fuel injector. This injector is tailored to meet the K50’s requirements, providing the necessary fuel delivery to support the engine’s performance and reliability.

Grouping of Engines

The 3016676 fuel injector is a versatile part that can be used across multiple Cummins engine models, including the K19, K38, and K50 engines. This compatibility allows for easier maintenance and repair, as technicians can use a single part for multiple engine types, reducing inventory needs and simplifying the repair process.

Role of Part 3016676 Fuel Injector in Engine Systems

The Part 3016676 Fuel Injector is integral to the efficient operation of several engine components. When integrated into an engine system, it works in concert with the aftercooler, cylinder head, cylinder head mounting, engine piston, and performance parts to ensure optimal engine performance.

Interaction with the Aftercooler

The aftercooler plays a role in cooling the compressed air from the turbocharger before it enters the combustion chamber. The fuel injector, by precisely metering the fuel into this cooled air, ensures a more efficient and complete combustion process. This interaction enhances the overall efficiency and power output of the engine.

Integration with the Cylinder Head

The cylinder head houses the fuel injector and is responsible for sealing the combustion chamber. The fuel injector’s precise fuel delivery directly into the combustion chamber, in conjunction with the cylinder head’s design, allows for better air-fuel mixture and improved combustion efficiency. This results in enhanced engine performance and reduced emissions.

Coordination with Cylinder Head Mounting

Proper cylinder head mounting is essential for maintaining the integrity of the combustion chamber and ensuring the fuel injector operates within specified tolerances. The mounting system must be robust to withstand the pressures and temperatures generated during combustion, allowing the fuel injector to function reliably and deliver fuel consistently.

Synergy with Engine Piston

The engine piston’s movement within the cylinder creates the compression necessary for combustion. The fuel injector’s timing and fuel delivery must be synchronized with the piston’s position to achieve the desired combustion event. This coordination ensures that the fuel is ignited at the optimal moment, maximizing power output and efficiency.

Enhancement of Performance Parts

Incorporating performance parts such as high-flow air filters, upgraded turbochargers, and performance exhaust systems requires a fuel injector that can match the increased airflow and fuel demands. The Part 3016676 Fuel Injector, with its precise fuel delivery capabilities, complements these performance enhancements by providing the necessary fuel to support higher power outputs and improved engine responsiveness.

Conclusion

The Cummins 3016676 Fuel Injector is a critical component in the efficient operation of diesel engines, particularly in commercial trucks. Its precise fuel delivery, robust design, and integration with modern engine management systems contribute to enhanced engine performance, fuel efficiency, and reduced emissions. Regular maintenance and understanding of its role within the engine system are essential for maximizing the benefits of this Cummins part.

-

BT Fijalkowski, Automotive Mechatronics Operational and Practical Issues Volume 1, Springer, 2011.

↩ -

Richard Stone, Introduction to Internal Combustion Engines, Fourth Edition, Macmillan, 2012.

↩ -

Libby Osgood, Gayla Cameron, and Emma Christensen, Engineering Mechanics: Statics, Creative Commons, 2024.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.