This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

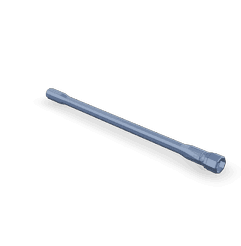

The Cummins 3017961 Push Rod is a component designed for use in heavy-duty truck engines. It serves a specific function within the engine’s valve train, contributing to the overall operation and performance of the vehicle. Understanding its role and functionality is key to maintaining and optimizing heavy-duty truck engines.

Basic Concepts of Push Rods

Push rods are mechanical components used in overhead valve (OHV) engines to transmit motion from the camshaft to the valves. They are typically long, slender metal rods that connect the camshaft’s lifters or followers to the rocker arms, which in turn operate the valves. The primary function of push rods is to ensure precise and timely valve operation, which is crucial for engine efficiency and performance. Push rods must be durable and accurately machined to withstand the high stresses and temperatures within an engine environment 1.

Purpose and Role of the 3017961 Push Rod

The Cummins 3017961 Push Rod is specifically engineered to fit within the valve train of Cummins heavy-duty truck engines. Its purpose is to transfer motion from the camshaft to the rocker arms, facilitating the opening and closing of the engine’s valves. This push rod contributes to engine performance and efficiency by ensuring that valves operate with the correct timing and force. Proper valve operation is vital for combustion efficiency, power output, and fuel economy in heavy-duty applications 2.

Key Features

The Cummins 3017961 Push Rod is characterized by several key features that enhance its functionality and durability. It is constructed from high-quality materials, typically steel, to withstand the rigors of heavy-duty engine operation. The design includes precise machining to ensure smooth operation and minimal friction. Additionally, the push rod may feature specific coatings or treatments to improve wear resistance and longevity. These features collectively contribute to the reliable performance of the push rod in demanding engine environments 3.

Benefits of Using the 3017961 Push Rod

Utilizing the Cummins 3017961 Push Rod in heavy-duty truck engines offers several advantages. These include improved engine performance due to precise valve operation, enhanced reliability under high-stress conditions, and increased longevity thanks to its durable construction. The benefits of using this push rod extend to the overall operation and maintenance of heavy-duty trucks, potentially reducing downtime and maintenance costs by ensuring consistent and reliable engine performance.

Troubleshooting and Maintenance Suggestions

Common issues with push rods may include wear, bending, or failure due to fatigue. Symptoms of push rod failure can manifest as engine misfires, reduced performance, or unusual noises from the valve train. Diagnosing push rod issues typically involves a thorough inspection of the valve train components, including the push rods, for signs of wear or damage. Routine maintenance practices for the Cummins 3017961 Push Rod include regular inspections during engine servicing, ensuring proper lubrication, and replacing worn or damaged components as necessary to maintain engine performance and reliability.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive and heavy-duty truck industries, Cummins is committed to producing high-quality engine components that meet the demanding requirements of commercial and industrial applications. The company’s focus on innovation, quality, and customer satisfaction has established it as a trusted name in the production of engine parts, including the Cummins 3017961 Push Rod.

Cummins Push Rod 3017961 Compatibility with K19, K38, and K50 Engines

The Cummins Push Rod part number 3017961 is a critical component designed to fit seamlessly within a range of Cummins engines, including the K19, K38, and K50 series. This push rod is engineered to ensure optimal performance and longevity in these engines, providing a reliable connection between the camshaft and the valve train.

K19 and K38 Engines

For the K19 and K38 engines, the 3017961 push rod is specifically designed to meet the stringent requirements of these high-performance engines. The K19 and K38 engines are known for their robust design and efficiency, and the push rod plays a vital role in maintaining the smooth operation of the valve train. Its precision engineering ensures that it can withstand the high pressures and temperatures typical of these engines, contributing to their overall reliability and efficiency.

K50 Engine

The K50 engine, another member of the Cummins engine family, also benefits from the use of the 3017961 push rod. This engine is engineered for heavy-duty applications, and the push rod’s design is tailored to handle the demanding conditions these engines often face. The 3017961 push rod’s durability and precision make it an ideal choice for maintaining the integrity of the valve train in the K50 engine, ensuring consistent performance and longevity.

Grouping for Efficiency

When considering the K19, K38, and K50 engines together, it is evident that the 3017961 push rod is a versatile component that can be used across multiple engine models. This compatibility allows for easier inventory management and maintenance, as technicians and fleet managers can use a single part number for multiple engine types. This not only simplifies the supply chain but also ensures that the correct part is readily available when needed, minimizing downtime and maintenance costs.

By understanding the compatibility and benefits of the Cummins Push Rod 3017961 across the K19, K38, and K50 engines, users can ensure that their engines operate at peak efficiency, with reliable and consistent performance.

Role of Part 3017961 Push Rod in Engine Systems

Part 3017961 Push Rod is an integral component in the operation of various engine systems, facilitating the transfer of motion from the camshaft to the valves. Its role is to transmit the rotational motion of the camshaft into linear motion, which is essential for the opening and closing of the engine’s valves.

Interaction with Base Part and Base Parts

The Push Rod interfaces with the base part and base parts, which serve as the foundational elements of the engine’s valve train. These base components provide the necessary support and alignment for the Push Rod, ensuring precise and reliable operation. The stability offered by the base parts is vital for the Push Rod to function correctly, as any misalignment can lead to inefficient valve operation and potential engine performance issues.

Coordination with EMBLever and Rocker

In conjunction with the EMBLever and rocker, the Push Rod plays a significant role in the valve actuation process. The EMBLever, often part of an overhead valve (OHV) system, receives motion from the Push Rod and transfers it to the rocker. The rocker then amplifies this motion to open the valve. This sequence ensures that the valves open and close at the correct times, maintaining the engine’s timing and efficiency.

Integration with Engine Installation Kit and On-Board Spares Kit

The Push Rod is also a key component in the engine installation kit and on-board spares kit. These kits are designed to facilitate the installation and maintenance of engine components. The inclusion of the Push Rod in these kits underscores its importance in both the initial setup and ongoing maintenance of the engine. Having a spare Push Rod on-board allows for quick replacements in case of failure, minimizing downtime and ensuring continuous operation.

Function within Overhaul Kit

In an overhaul kit, the Push Rod is essential for restoring the engine’s valve train to optimal condition. During an engine overhaul, worn or damaged Push Rods are replaced to ensure that the valve train operates smoothly and efficiently. This contributes to the overall performance and longevity of the engine.

Relationship with PDC and Lever

The Push Rod works in tandem with the PDC (possibly referring to a specific component like a Pushrod Distribution Center) and lever to maintain the integrity of the valve train system. The PDC might distribute the motion from the camshaft to multiple Push Rods, while the lever could be part of a secondary motion transfer system. The Push Rod ensures that this motion is transmitted accurately and consistently, which is fundamental for the engine’s operation.

Support from Base and Parts

Finally, the Push Rod relies on the base and various parts for structural support and precise alignment. These components work together to create a stable environment for the Push Rod to operate within, ensuring that the valve train functions as intended. The interplay between these parts is essential for the reliable and efficient performance of the engine.

Conclusion

The Cummins 3017961 Push Rod is a critical component in the valve train of heavy-duty truck engines, ensuring precise and reliable valve operation. Its durable construction, precise machining, and compatibility with various Cummins engines make it an essential part for maintaining engine performance and efficiency. Regular maintenance and timely replacement of worn components are key to maximizing the benefits of this push rod and ensuring the longevity of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.