This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

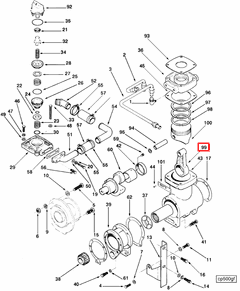

The 3018151 Compressor Connecting Rod, manufactured by Cummins, is a specialized component designed for use in compressor systems. This part facilitates the mechanical linkage between the compressor’s piston and crankshaft, ensuring efficient energy transfer and smooth operation of the compressor.

Basic Concepts

Compressor connecting rods are integral to the functionality of compressor systems. They serve as the mechanical link between the piston and the crankshaft, allowing the linear motion of the piston to be converted into rotational motion of the crankshaft. This conversion is fundamental to the operation of the compressor, as it enables the compression of air or gas, which is then used for various applications within the truck’s engine system 1.

Role and Function

The 3018151 is designed to operate within the compressor system of a truck, connecting the piston to the crankshaft. Its role involves transmitting the force generated by the piston’s movement to the crankshaft, thereby contributing to the compressor’s ability to compress air or gas. This interaction is vital for the efficient operation of the compressor, as it ensures that the energy produced by the piston is effectively utilized to drive the compressor’s output.

Key Features

The 3018151 is characterized by several design elements that enhance its performance and durability. These include precision machining for accurate fit and function, high-strength materials to withstand the stresses of compressor operation, and a design that minimizes friction and wear. These features contribute to the rod’s ability to operate efficiently under the demanding conditions of a truck’s compressor system.

Benefits

The use of the 3018151 offers several advantages. Its design and construction contribute to improved efficiency and reliability of the compressor system. By ensuring smooth and efficient energy transfer between the piston and crankshaft, this component helps to maintain the compressor’s performance over time. Additionally, its durability and resistance to wear contribute to the longevity of the compressor system, reducing the need for frequent replacements or repairs.

Installation and Maintenance

Proper installation of the 3018151 is crucial for ensuring its effective operation within the compressor system. Recommended procedures include careful alignment with the piston and crankshaft, secure fastening, and verification of proper clearances. Regular maintenance, such as inspection for wear and lubrication of moving parts, is also important for ensuring optimal performance and longevity of the compressor system.

Troubleshooting

Common issues associated with compressor connecting rods may include wear, misalignment, or failure due to excessive stress. Troubleshooting steps may involve inspection for signs of wear or damage, checking alignment and clearances, and assessing the condition of related components such as the piston and crankshaft. Addressing these issues promptly can help to maintain the efficiency and reliability of the compressor system.

Cummins Overview

Cummins is a well-established manufacturer with a reputation for producing high-quality automotive and industrial components. With a history of innovation and commitment to excellence, Cummins has earned a strong reputation in the industry for its reliable and durable products. The company’s focus on quality and performance is evident in its range of components, including the 3018151, which is designed to meet the demanding requirements of modern compressor systems.

Cummins Compressor Connecting Rod 3018151 Compatibility

The 3018151 is designed to fit a variety of Cummins engines, ensuring a reliable connection between the piston and crankshaft. Below is a detailed overview of the engines that this part is compatible with:

Cummins B Series Engines

- 4B3.9

- 6B5.9

- B5.9 G

Cummins C Series Engines

- C GAS PLUS CM556

- C8.3 G

Cummins ISB Engines

- ISB CM550

- ISB CM570

Cummins ISC Engines

- ISC CM554

- ISC CM570

Cummins ISL Engines

- ISL CM554

- ISL CM570

Cummins ISM Engines

- ISM CM570

Cummins ISX Engines

- ISX CM570

Cummins K Series Engines

- K19

- K38

- K50

Cummins L10 Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

Cummins M11 Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

Cummins N14 Engines

- N14 CELECT

- N14 CELECT PLUS

- N14 MECHANICAL

Cummins QSB Engines

- QSB5.9 44 CM550

Cummins NH/NT Engines

- NH/NT 855

This comprehensive compatibility ensures that the 3018151 can be used across a wide range of Cummins engines, providing a versatile solution for maintenance and repair needs.

Role of Part 3018151 Compressor Connecting Rod in Engine Systems

The 3018151 is integral to the efficient operation of various engine components. It serves as a pivotal link between the piston and the crankshaft in the 1 Cylinder Air (Painted) Compressor, ensuring smooth and synchronized movement. This connection is vital for the conversion of linear motion of the piston into rotational motion of the crankshaft.

In the 1 Cylinder Air Compressor and 1 Cylinder Compressor Crankcase, the connecting rod maintains the alignment and balance necessary for consistent compression and decompression cycles. It works in tandem with the Accessory Drive and Air Compressor Drive to transfer power efficiently from the engine to the compressor components.

When integrated with the Air 1-Cylinder Compressor, the connecting rod facilitates the smooth operation of the Compressor Crankcase and Crankcase, ensuring that the compression process is uniform and reliable. This is particularly important in the Compressor Conversion Kit, where the connecting rod must adapt to different compressor configurations while maintaining performance standards.

The connecting rod also plays a significant role in the Air Compressor Kit and Air Compressor SPO, where it ensures that the Piston and Connecting Rod assembly functions seamlessly. This is essential for the overall efficiency of the Compressor Air system, especially in applications requiring high-pressure output, such as those indicated by the Compressor Air 2.2.2. Head Code.

In systems like the Fuel Pump Compressor Assembly and Kit Compressor, the connecting rod ensures that the fuel pump operates in sync with the compressor, enhancing the overall performance of the engine. Additionally, in the Support and Drive and Air Compressor Support and Drive components, the connecting rod contributes to the stability and durability of the compressor system.

The part is also relevant in the Thermostat Housing and Vacuum Pump systems, where it helps maintain the precise mechanical timing required for optimal engine performance. In the Vacuum Pump Crankcase, the connecting rod ensures that the vacuum pump operates efficiently, contributing to the engine’s vacuum system integrity.

Overall, the 3018151 is a fundamental component in various engine systems, ensuring the reliable and efficient transfer of motion and power within the compressor and related assemblies.

Conclusion

The 3018151 Compressor Connecting Rod is a critical component in the efficient operation of compressor systems. Its role in facilitating the mechanical linkage between the piston and crankshaft ensures smooth and efficient energy transfer, contributing to the overall performance and reliability of the compressor. With its precision machining, high-strength materials, and design that minimizes friction and wear, this Cummins part is well-suited to withstand the demanding conditions of modern engine systems. Proper installation, regular maintenance, and prompt troubleshooting are essential for maximizing the benefits of this component, ensuring the longevity and efficiency of the compressor system.

-

Wang, Y. (2007). Introduction to Engine Valvetrains. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.