This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Barrel and Plunger 3018325 is a component manufactured by Cummins, a well-established name in the commercial truck industry. This part is integral to the operation of commercial trucks, particularly in the context of fuel injection systems. Cummins is renowned for its commitment to quality and innovation, ensuring that components like the Barrel and Plunger 3018325 meet the rigorous demands of commercial truck operations 1.

Basic Concepts

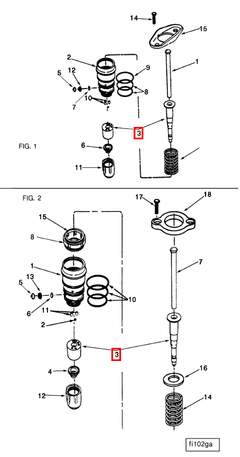

The operation of a barrel and plunger system is grounded in fundamental mechanical principles. This system comprises a cylindrical barrel and a plunger that moves within it. The interaction between these components allows for the precise control of fuel delivery in diesel engines. As the plunger moves within the barrel, it creates pressure that forces fuel through the injector nozzle into the combustion chamber 2.

Purpose and Function

The Barrel and Plunger 3018325 plays a significant role in the operation of a truck’s fuel injection system. It is responsible for the accurate metering and delivery of fuel to the engine’s combustion chambers. This precise fuel delivery is vital for maintaining engine performance, ensuring efficient combustion, and contributing to the overall reliability of the truck’s engine 3.

Key Features

The Barrel and Plunger 3018325 is characterized by several key features that enhance its functionality. It is constructed from high-quality materials to withstand the high pressures and temperatures within the fuel injection system. The design of the barrel and plunger is meticulously engineered to ensure a tight seal, minimizing fuel leakage and maximizing injection efficiency. Additionally, the component may feature unique attributes such as advanced coatings or precision machining to further improve performance and durability.

Benefits

The advantages of the Barrel and Plunger 3018325 include improved fuel efficiency, enhanced engine performance, and reliability in demanding commercial truck applications. By ensuring precise fuel delivery, this component contributes to more efficient combustion, which can lead to better fuel economy. Its robust construction and precise engineering also enhance the durability and reliability of the fuel injection system, making it well-suited for the rigors of commercial truck operations.

Troubleshooting and Maintenance

Identifying common issues with the Barrel and Plunger 3018325 and implementing recommended maintenance practices are crucial for ensuring optimal performance and longevity. Regular inspection for signs of wear, leakage, or malfunction can help in early detection of potential problems. Maintenance practices may include cleaning, lubrication, and, when necessary, replacement of worn components to maintain the efficiency and reliability of the fuel injection system.

Installation Considerations

When installing the Barrel and Plunger 3018325, it is important to consider compatibility with specific truck models and engine types. Following manufacturer guidelines and any special installation procedures or requirements ensures proper integration into the fuel injection system. Attention to detail during installation helps prevent issues such as leaks or inefficient fuel delivery, contributing to the overall performance of the engine.

Performance Optimization

Maximizing the performance of the Barrel and Plunger 3018325 involves proper calibration, regular inspection, and proactive maintenance strategies. Ensuring that the component is correctly calibrated to the engine’s specifications can enhance fuel delivery precision. Regular inspections help identify wear or damage early, allowing for timely maintenance or replacement. Proactive maintenance, including cleaning and lubrication, can extend the component’s service life and maintain optimal engine performance.

Cummins Overview

Cummins has a long-standing reputation in the industry for innovation and quality in manufacturing commercial truck components. Founded with a commitment to excellence, Cummins has consistently delivered reliable and high-performance parts that meet the demanding requirements of commercial truck operations. Their dedication to research and development ensures that components like the Barrel and Plunger 3018325 continue to evolve, offering improved efficiency, performance, and durability for the fleets that rely on them.

Role of Part 3018325 Barrel and Plunger in Engine Systems

The part 3018325 Barrel and Plunger is an essential component in the operation of various engine systems, particularly in fuel injection mechanisms. Its primary function is to facilitate the precise delivery of fuel into the combustion chamber, ensuring optimal engine performance and efficiency.

Integration with Injectors

In fuel injection systems, the Barrel and Plunger work in conjunction with injectors to control the amount and timing of fuel delivery. The plunger moves within the barrel to create pressure, which is then used to atomize the fuel as it is sprayed into the combustion chamber. This precise control is vital for maintaining the correct air-fuel ratio, which is necessary for efficient combustion and reduced emissions.

Role in Injector Repair Kits

When it comes to injector repair kits, the Barrel and Plunger are often included as key replacement parts. Over time, wear and tear can affect the performance of these components, leading to issues such as decreased fuel efficiency and engine misfires. Replacing the Barrel and Plunger as part of a repair kit helps restore the injector’s functionality, ensuring that it operates within the manufacturer’s specifications.

Pressure-Time Delivery (PTD) Systems

In Pressure-Time Delivery (PTD) injectors, the Barrel and Plunger are integral to the system’s operation. These injectors rely on the precise movement of the plunger within the barrel to build and release pressure at specific intervals. This timing is crucial for synchronizing fuel delivery with the engine’s combustion cycle, enhancing overall performance and fuel economy.

Performance Parts

For those looking to upgrade their engine’s performance, high-quality Barrel and Plunger components are often included in performance parts packages. These upgraded parts are designed to withstand higher pressures and temperatures, allowing for more aggressive fuel delivery strategies. This can result in increased power output and improved throttle response.

Less Link Injectors

In Less Link injectors, the Barrel and Plunger play a role in simplifying the fuel delivery process. By reducing the number of moving parts, these injectors aim to increase reliability and ease of maintenance. The Barrel and Plunger in these systems are engineered to provide consistent performance under a variety of operating conditions.

Pressure-Time Delivery Injector

Finally, in Pressure-Time Delivery injectors, the Barrel and Plunger are responsible for creating the high-pressure environment needed for efficient fuel atomization. This is particularly important in direct injection systems, where the fuel is sprayed directly into the combustion chamber. The precise movement of the plunger within the barrel ensures that the fuel is delivered at the optimal moment, contributing to better combustion efficiency and reduced emissions.

Conclusion

The Barrel and Plunger 3018325 by Cummins is a critical component in the operation of commercial truck fuel injection systems. Its precise design and robust construction ensure efficient fuel delivery, contributing to enhanced engine performance and reliability. Regular maintenance and proper installation are key to maximizing the benefits of this component, ensuring optimal engine operation and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.