This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Lubricating Oil Pump Shaft, identified by part number 3021361, is a component manufactured by Cummins, a leader in diesel engine technology. This shaft is integral to the operation of heavy-duty trucks, facilitating the efficient circulation of lubricating oil throughout the engine. Cummins’ reputation for quality and innovation underscores the reliability and performance of this component .

Function and Operation

The Lubricating Oil Pump Shaft operates within the oil pump to circulate oil through the engine. It drives the rotation of the pump’s internal components, which draw oil from the sump and deliver it under pressure to various engine parts. Consistent oil flow is vital for maintaining engine performance and longevity, as it reduces friction between moving parts, dissipates heat, and removes contaminants .

Key Features

The Lubricating Oil Pump Shaft is characterized by its precision engineering and durable materials. It is crafted to exacting standards to ensure smooth operation and longevity. The shaft is made from high-quality materials that resist wear and corrosion, enhancing its reliability. Its design includes features that optimize oil flow and minimize friction, contributing to the overall efficiency of the oil pump .

Benefits

The advantages of the Lubricating Oil Pump Shaft include improved engine lubrication, which leads to reduced friction and wear on engine components. This results in enhanced engine efficiency and contributes to the overall health and longevity of the engine. By ensuring a consistent supply of oil to critical engine parts, the shaft helps maintain optimal engine performance under various operating conditions .

Installation and Maintenance

Proper installation of the Lubricating Oil Pump Shaft is crucial for ensuring optimal performance. It should be installed according to the manufacturer’s guidelines to avoid issues such as misalignment or improper seating, which can lead to inefficiencies or damage. Regular maintenance practices, such as checking for wear and ensuring the shaft is free from contaminants, are recommended to maintain its performance. Identifying and addressing common issues, such as unusual noises or changes in oil pressure, can prevent more significant problems .

Troubleshooting

Common problems associated with the Lubricating Oil Pump Shaft may include wear, misalignment, or damage due to contaminants in the oil. Diagnostic procedures for identifying issues may involve checking oil pressure, inspecting the shaft for signs of wear or damage, and ensuring the oil pump is functioning correctly. Recommended solutions or repairs may include cleaning or replacing the shaft, adjusting alignment, or addressing issues with the oil pump to restore proper function .

Cummins Overview

Cummins Inc. has a long-standing history in the automotive industry, known for its commitment to quality and innovation. As a leading manufacturer of diesel engines and related components, Cummins has established a reputation for producing reliable and high-performance parts. The company’s dedication to advancing diesel technology and meeting the needs of its customers underscores its position as a trusted provider in the industry .

Compatibility with N14 MECHANICAL and NH/NT 855 Engines

The Cummins part 3021361, identified as a Lubricating Oil Pump Shaft, is designed to fit seamlessly into the N14 MECHANICAL and NH/NT 855 engines. This part is integral to the engine’s lubrication system, ensuring that oil is efficiently circulated throughout the engine to reduce friction and wear on moving parts.

In the N14 MECHANICAL engine, the lubricating oil pump shaft works in conjunction with the oil pump to maintain optimal oil pressure and flow. This is crucial for the engine’s performance and longevity, as it helps to keep all internal components adequately lubricated under varying operating conditions.

Similarly, in the NH/NT 855 engine, the lubricating oil pump shaft plays a vital role in the lubrication system. It ensures that the oil pump can effectively draw oil from the sump and distribute it to the various parts of the engine, including the crankshaft, camshaft, and other moving components. This consistent lubrication is essential for maintaining engine efficiency and preventing damage from overheating or metal-on-metal contact.

Both engines benefit from the precision engineering of the Cummins part 3021361, which is designed to meet the specific requirements of these engine models. The compatibility of this part with both the N14 MECHANICAL and NH/NT 855 engines underscores its versatility and importance in maintaining the health and performance of these engines .

Role of Part 3021361 Lubricating Oil Pump Shaft in Engine Systems

The lubricating oil pump shaft, identified by part number 3021361, is an integral component within various engine systems, ensuring the efficient circulation of lube oil throughout the engine. This shaft is specifically designed to work in conjunction with the lubricating oil pump, which is responsible for maintaining the necessary oil pressure to lubricate moving parts and reduce friction.

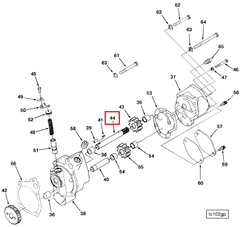

Integration with Lubricating Oil Pump

The lubricating oil pump shaft is a key element in the lubricating oil pump assembly. It rotates within the pump housing, driven by the hydraulic pump drive mechanism. This rotation facilitates the movement of lube oil from the sump to various engine components, ensuring they remain well-lubricated.

Interaction with Hydraulic Systems

In engines equipped with hydraulic systems, the lubricating oil pump shaft plays a dual role. It not only supports the lubrication process but also interacts with the hydraulic pump. The hydraulic pump drive, connected to the shaft, ensures that hydraulic fluid is circulated effectively, contributing to the operation of hydraulic components within the engine.

Conversion Kit Applications

When utilizing a conversion kit that modifies the engine’s lubrication system, the lubricating oil pump shaft remains a central component. The shaft must be compatible with the new configuration to ensure seamless integration and continued efficient operation of the lube pump.

Base Parts and Lubricating Oil Filter

The lubricating oil pump shaft is also essential in base parts configurations, where it ensures the lube oil is adequately pressurized before passing through the lubricating oil filter. This filtration process removes contaminants, enhancing the quality of the oil delivered to critical engine components.

Oil Pump and Pump Lubricating Oil Assembly

Within the broader oil pump system, the shaft is a fundamental part of the pump lubricating oil assembly. Its precise engineering and robust construction are vital for the reliable operation of the oil pump, ensuring consistent oil flow and pressure maintenance throughout the engine’s operational life .

Conclusion

The Lubricating Oil Pump Shaft part number 3021361 by Cummins is a critical component in the lubrication system of heavy-duty engines. Its precise engineering, durable materials, and compatibility with various engine models ensure efficient oil circulation, reduced friction, and enhanced engine performance and longevity. Proper installation, regular maintenance, and timely troubleshooting are essential to maximize the benefits of this component.

: Sheng, G. (2012). *Vehicle Noise, Vibration and Sound Quality*. SAE International.

: Norman, A. (2016). *Diesel Technology Fundamentals Service Repair Eighth Edition*. The Goodheart-Willcox Company Inc.

: Singh, D. K. (2024). *Dictionary of Mechanical Engineering*. Springer Nature.

: Denton, T., & Pells, H. (2022). *Automotive Technician Training, Second Edition*. Routledge.SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.