This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

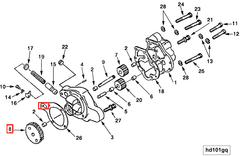

The Lubricating Oil Pump Gear (Part #3025281) by Cummins is a component designed to facilitate the operation of heavy-duty trucks. This gear is integral to the oil pump system, ensuring that engine components receive adequate lubrication. Its role is significant in maintaining the efficiency and longevity of the engine by promoting smooth operation and reducing wear on moving parts 1.

Function and Operation

The Lubricating Oil Pump Gear operates within the oil pump system to maintain proper lubrication of engine components. It works by meshing with another gear within the pump, creating a rotational motion that draws oil from the sump and delivers it under pressure to various parts of the engine. This process ensures that critical components such as bearings, pistons, and camshafts are continuously bathed in oil, which reduces friction and heat, thereby enhancing the overall performance and durability of the engine 2.

Key Features

The Lubricating Oil Pump Gear is constructed from high-quality materials that are resistant to wear and corrosion, ensuring durability in demanding environments. Its design specifications include precise gear teeth that allow for efficient oil transfer with minimal noise and vibration. Additionally, the gear may feature unique characteristics such as a special coating or treatment that further enhances its performance and longevity 3.

Benefits

The Lubricating Oil Pump Gear offers several benefits that contribute to the overall health of the engine. By ensuring consistent and adequate lubrication, it helps to maintain optimal engine performance. The gear’s durable construction and efficient design contribute to enhanced durability, reducing the likelihood of premature failure. Furthermore, its role in the oil circulation system increases the efficiency of oil distribution throughout the engine, which is vital for sustained operation under heavy-duty conditions 4.

Installation and Maintenance

Proper installation of the Lubricating Oil Pump Gear is crucial for ensuring its effectiveness and longevity. It should be installed according to the manufacturer’s guidelines, which may include specific torque settings and alignment procedures. Regular maintenance practices, such as periodic inspection for wear and proper lubrication, are recommended to ensure optimal performance. Additionally, following the manufacturer’s service intervals for oil changes can help maintain the gear’s efficiency and prolong its service life.

Troubleshooting

Common issues with the Lubricating Oil Pump Gear may include noise, reduced oil pressure, or gear wear. Troubleshooting these problems often involves inspecting the gear for signs of damage or misalignment, checking the oil for contamination, and ensuring that the pump is receiving adequate power. Solutions may range from simple adjustments to more complex repairs or replacements, depending on the severity of the issue.

Manufacturer - Cummins

Cummins Inc. is a well-established company with a strong reputation in the automotive and heavy-duty truck industry. Known for its commitment to producing high-quality components, Cummins has a history of innovation and excellence. The company’s dedication to quality is evident in its rigorous testing and quality control processes, which ensure that each part, including the Lubricating Oil Pump Gear, meets the highest standards of performance and reliability.

Cummins Lubricating Oil Pump Gear 3025281 Compatibility

The Cummins part number 3025281, which is a Lubricating Oil Pump Gear, is designed to fit seamlessly within specific engine models. This part is integral to the proper functioning of the engine’s lubrication system, ensuring that oil is distributed efficiently to various engine components.

N14 MECHANICAL Engines

The N14 MECHANICAL engine series benefits from the precise engineering of the 3025281 gear. This part is crucial in maintaining the oil flow necessary for the engine’s smooth operation, particularly in heavy-duty applications where consistent lubrication is vital.

NH/NT 855 Engines

Similarly, the NH/NT 855 engines are equipped to utilize the 3025281 gear. This part ensures that the oil pump operates effectively, providing the necessary lubrication to the engine’s moving parts. The compatibility of this gear with the NH/NT 855 series underscores its versatility and importance in maintaining engine performance.

In both engine series, the 3025281 gear is engineered to meet the rigorous demands of high-performance engines, ensuring longevity and reliability.

Role of Part 3025281 Lubricating Oil Pump Gear in Engine Systems

The Lubricating Oil Pump Gear is an integral component within various engine systems, ensuring the efficient circulation of lube oil throughout the engine. This gear is specifically designed to work in conjunction with the lubricating oil pump, where it plays a significant role in maintaining the proper lubrication of engine components.

In the context of an Engine Spares Kit, the lubricating oil pump gear ensures that the replacement or repair of the oil pump is carried out with precision, maintaining the engine’s lubrication system integrity.

When integrated into a Hydraulic Pump Drive system, the gear assists in driving the hydraulic pump, which in turn powers various hydraulic components within the engine, ensuring smooth operation and reduced wear on moving parts.

Within the Lubricating Oil and Filter Hardware Pump assembly, the gear works in tandem with other components to deliver a consistent flow of filtered lube oil, which is essential for the longevity and performance of the engine.

In systems utilizing an Oil Pan and Dipstick, the gear helps in maintaining the oil level by ensuring a steady supply of lube oil is pumped from the oil pan, thus preventing oil starvation and subsequent engine damage.

The gear is also a key component in the Oil Pump assembly, where it ensures that oil is effectively circulated through the engine, reducing friction and heat, and protecting critical engine components from wear.

Furthermore, in a Fuel Pump system, although primarily designed for lube oil, the gear’s efficient operation can indirectly influence fuel system performance by ensuring the engine runs smoothly and efficiently.

Overall, the Lubricating Oil Pump Gear is a fundamental component in ensuring the lubrication system’s effectiveness, contributing to the engine’s overall performance, durability, and reliability.

Conclusion

The Lubricating Oil Pump Gear (Part #3025281) by Cummins plays a crucial role in the lubrication system of heavy-duty engines. Its precise engineering, durable construction, and efficient operation ensure that engine components receive consistent and adequate lubrication, which is vital for maintaining engine performance, durability, and reliability. Proper installation, regular maintenance, and timely troubleshooting are essential for maximizing the benefits of this Cummins part.

-

Reif, Konrad Ed. Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer, 2014.

↩ -

Rajamani, Rajesh. Vehicle Dynamics and Control. Springer, 2005.

↩ -

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons, 2019.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.