This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

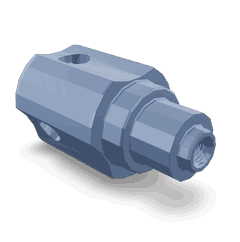

The Idle Spring Plunger Guide, manufactured by Cummins, is a component integral to the operation of heavy-duty trucks. Cummins, a renowned name in the automotive industry, particularly in diesel engines and related components, produces this part to enhance the functionality and reliability of truck engines. This guide provides a foundational understanding of the Idle Spring Plunger Guide, its role, and its manufacturer.

Function and Operation

The Idle Spring Plunger Guide operates within the engine system by facilitating the movement of the idle spring plunger. This component interacts with other engine parts to regulate the idle speed of the engine. Its operation ensures that the engine maintains a consistent idle, which is crucial for the smooth functioning of the vehicle, especially during periods of low demand or when the vehicle is stationary. The guide’s precise function within the engine system contributes to the overall efficiency and performance of the truck 1.

Purpose of the Idle Spring Plunger Guide

The Idle Spring Plunger Guide plays a specific role in the operation of a truck by contributing to engine efficiency and reliability. It ensures that the idle speed is maintained at an optimal level, which is vital for the engine’s performance under various operating conditions. This component helps in reducing unnecessary fuel consumption during idle periods and contributes to the longevity of the engine by ensuring smooth operation 2.

Key Features

The Idle Spring Plunger Guide is characterized by its robust design and the use of high-quality materials. These features ensure durability and reliable performance under the demanding conditions typical of heavy-duty truck operations. The guide’s design allows for precise control over the idle spring plunger’s movement, enhancing the engine’s performance. Additionally, its construction from durable materials ensures resistance to wear and tear, contributing to its longevity 3.

Benefits

The advantages provided by the Idle Spring Plunger Guide include improved engine performance, increased durability, and potential cost savings for fleet operators. By ensuring optimal idle speed, the guide contributes to better fuel efficiency and reduced emissions. Its durable construction means less frequent replacements, leading to cost savings over time. Furthermore, the reliable performance of the guide contributes to the overall reliability of the truck, reducing downtime and maintenance costs.

Installation Process

Proper installation of the Idle Spring Plunger Guide is crucial for ensuring optimal performance. The process involves carefully positioning the guide within the engine system, ensuring it is securely fastened and correctly aligned with other components. It is important to follow manufacturer guidelines during installation to avoid any issues that could affect the engine’s performance. Regular checks post-installation can help ensure the guide is functioning as intended.

Maintenance and Troubleshooting

Regular maintenance practices for the Idle Spring Plunger Guide include periodic inspections for signs of wear or damage. Cleaning the guide and its surrounding components can prevent buildup that might affect its operation. Troubleshooting common issues, such as inconsistent idle speed, may involve checking the guide’s alignment and condition. Addressing these issues promptly can help maintain the engine’s performance and longevity.

Common Failure Modes

Typical failure modes associated with the Idle Spring Plunger Guide include wear and tear due to continuous operation and exposure to high temperatures. Preventive measures to mitigate these issues include regular maintenance checks and timely replacement of the guide if signs of significant wear are detected. Ensuring the guide is correctly installed and aligned can also prevent premature failure.

Impact on Engine Performance

The Idle Spring Plunger Guide influences overall engine performance by ensuring optimal idle speed, which contributes to fuel efficiency, emissions control, and power output. Its role in maintaining a consistent idle allows the engine to operate smoothly under various conditions, enhancing the truck’s performance and reliability. The guide’s impact on these aspects underscores its importance in the engine system.

Cummins: A Brief Overview

Cummins Inc. is a global leader in the design, manufacture, and distribution of diesel and natural gas engines, as well as related technologies. With a rich history dating back to the early 20th century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. The company’s product range includes engines, filtration systems, and power generation equipment, serving a wide array of industries and applications. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the manufacture of diesel engines and related components.

Idle Spring Plunger Guide Compatibility with Cummins Engines

The Idle Spring Plunger Guide part number 3036473, manufactured by Cummins, is a critical component in various engine models. This guide ensures the proper functioning of the idle spring mechanism, which is essential for maintaining the engine’s idle speed and overall performance.

K-Series Engines

The Idle Spring Plunger Guide is compatible with the following K-Series engines:

- K19

- K38

- K50

These engines are known for their robust design and reliability, often used in heavy-duty applications.

L-Series Engines

The part is also suitable for the:

- L10 MECHANICAL

This engine is recognized for its mechanical simplicity and durability, making it a preferred choice in various industrial applications.

M-Series Engines

The Idle Spring Plunger Guide fits the following M-Series engines:

- M11 CELECT PLUS

- M11 MECHANICAL

Both of these engines are equipped with advanced technology and are designed for high-performance and efficiency.

N-Series Engines

The guide is also compatible with:

- N14 MECHANICAL

This engine is known for its power and reliability, often used in demanding environments.

NH/NT Series Engines

The part fits the:

- NH/NT 855

This engine is designed for heavy-duty applications and is known for its durability and performance.

QSK Series Engines

The Idle Spring Plunger Guide is also suitable for:

- QSK19 CM500

This engine is engineered for high-performance and is widely used in various industrial and commercial applications.

V-Series Engines

The guide is compatible with the following V-Series engines:

- V28

- V903

These engines are known for their power and efficiency, making them suitable for a wide range of applications.

Role of Part 3036473 Idle Spring Plunger Guide in Engine Systems

The Idle Spring Plunger Guide, identified by part number 3036473, is an integral component within various engine systems, particularly those involving fuel delivery and management. This guide plays a significant role in ensuring the proper function and efficiency of several key components.

Integration with Fuel Systems

- Fuel Pump and Calibration Code: The Idle Spring Plunger Guide works in conjunction with the fuel pump and its associated calibration code. It helps maintain consistent fuel pressure and flow, which is essential for the engine’s idle stability and overall performance.

- Fuel Tubing: By guiding the spring plunger, this part ensures that the fuel tubing operates within specified parameters. This is vital for preventing fuel leaks and ensuring that the fuel delivery system remains efficient and reliable.

- Idle Spring Pack: The guide is a critical element of the idle spring pack, assisting in the modulation of spring tension. This, in turn, affects the idle speed and smoothness of the engine.

Interaction with Governor Pumps

- W-W Governor Pump: In systems utilizing a W-W governor pump, the Idle Spring Plunger Guide ensures that the governor functions correctly. This is important for maintaining the desired engine speed under varying load conditions.

- Fuel and W-W Governor Pump: The guide facilitates the interaction between the fuel system and the W-W governor pump, ensuring that fuel delivery is synchronized with engine demand.

Specific Pump Codes

- Pump Code CPL 155, CPL 160, CPL 187, CPL 196, CPL 204, CPL 218, CPL-126, CPL189, CPL205: Across these various pump codes, the Idle Spring Plunger Guide ensures that the plunger within the pump operates smoothly and efficiently. This is essential for the accurate delivery of fuel, which directly impacts engine performance and fuel economy.

Overall System Efficiency

The Idle Spring Plunger Guide contributes to the overall efficiency of the engine system by ensuring that all moving parts within the fuel delivery mechanism operate harmoniously. This not only enhances engine performance but also contributes to the longevity and reliability of the engine components.

Conclusion

The Idle Spring Plunger Guide (part number 3036473) by Cummins is a vital component in the operation of heavy-duty truck engines. Its role in regulating idle speed, ensuring fuel efficiency, and contributing to engine reliability underscores its importance. Proper installation, maintenance, and understanding of its function are crucial for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.