This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

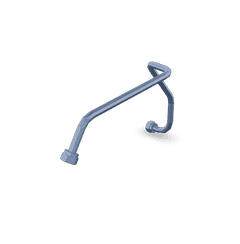

The Compressor Water Outlet Tube, identified by Part #3038036, is a component manufactured by Cummins, a renowned name in the automotive industry. This part is integral to the cooling systems of heavy-duty truck engines, ensuring they operate within optimal temperature ranges. Cummins, with its extensive history and reputation for quality, provides this component as part of its commitment to enhancing engine performance and durability 4.

Basic Concepts and Functionality

The Compressor Water Outlet Tube operates on fundamental principles of fluid dynamics and thermal management. It plays a role in the engine’s cooling system by directing coolant flow from the compressor to other parts of the cooling system. This process helps in dissipating heat generated by the engine, maintaining a stable operating temperature. The tube’s design allows for efficient coolant circulation, which is vital for preventing engine overheating and ensuring consistent performance 2.

Purpose and Role in Truck Operation

In the context of heavy-duty truck engines, the Compressor Water Outlet Tube serves a specific purpose. It ensures that the coolant, after absorbing heat from the compressor, is effectively routed to the radiator or other cooling components. This contributes to the overall efficiency and performance of the truck by maintaining engine temperature within desired limits, which is particularly important under heavy load or in extreme operating conditions 3.

Key Features

The Compressor Water Outlet Tube is characterized by several key features that enhance its functionality and durability. Its design is engineered to withstand high pressures and temperatures typical in heavy-duty engine environments. The material composition, often a durable alloy, ensures resistance to corrosion and wear. Additionally, the tube may feature specific connectors or fittings that ensure a secure and leak-free connection within the cooling system 1.

Benefits

The advantages of the Compressor Water Outlet Tube include improved engine cooling efficiency, which is crucial for the longevity and performance of heavy-duty engines. Its durable construction contributes to the overall reliability of the cooling system. Furthermore, efficient cooling can lead to better fuel economy and reduced emissions, aligning with industry trends towards more environmentally friendly vehicle operation 2.

Troubleshooting and Maintenance

Common issues with the Compressor Water Outlet Tube may include leaks, blockages, or corrosion. Regular inspection and maintenance are recommended to ensure optimal performance. This includes checking for signs of wear or damage, ensuring secure connections, and replacing the tube if any issues are detected. Proper maintenance of this component is key to preventing engine overheating and ensuring the longevity of the cooling system 3.

Integration with Engine Systems

The Compressor Water Outlet Tube interacts with various components within the engine system. It works in conjunction with the radiator, thermostat, and water pump to maintain efficient cooling. This integration ensures that coolant is effectively circulated throughout the engine, absorbing heat and dissipating it through the radiator. The tube’s role in this system is vital for maintaining engine health and performance 4.

Cummins: Manufacturer Overview

Cummins, the manufacturer of the Compressor Water Outlet Tube, has a long-standing reputation in the automotive industry. Known for its high-quality engine components, Cummins is committed to innovation and excellence in heavy-duty truck engine manufacturing. The company’s history is marked by a dedication to producing reliable and efficient engine parts, making it a trusted name in the industry 4.

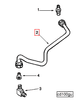

Cummins Compressor Water Outlet Tube 3038036 Compatibility

The Cummins Compressor Water Outlet Tube, part number 3038036, is designed to fit seamlessly with a range of NH/NT engines. This part is crucial for the efficient operation of the engine’s cooling system, ensuring that the compressor section is adequately cooled.

NH/NT 855 Engines

For the NH/NT 855 engines, the Compressor Water Outlet Tube 3038036 is engineered to integrate perfectly with the engine’s design. This compatibility ensures that the water outlet tube functions optimally, maintaining the necessary cooling flow and preventing overheating of the compressor.

Group Compatibility

The part 3038036 is not limited to a single engine model but is compatible with a group of NH/NT engines. This versatility makes it a valuable component for technicians and fleet managers who need to maintain a variety of engines within the NH/NT series. The design of the tube ensures it fits well with the specified engine models, providing a reliable solution for cooling needs.

Installation and Usage

When installing the Compressor Water Outlet Tube 3038036, it is essential to follow the manufacturer’s guidelines to ensure proper fit and function. This part is a critical component in the engine’s cooling system, and its correct installation is vital for the engine’s longevity and performance.

Role of Part 3038036 Compressor Water Outlet Tube in Engine Systems

The Compressor Water Outlet Tube is an integral component within the air compressor system, specifically designed to facilitate the efficient routing of coolant and water within the system. This component is meticulously engineered to interface with various plumbing systems associated with the compressor.

Integration with Compressor Plumbing

In the air compressor plumbing system, the Compressor Water Outlet Tube serves as a conduit for the coolant, ensuring that it is effectively circulated from the compressor coolant plumbing to other critical areas. This circulation is essential for maintaining optimal operating temperatures and preventing overheating of the compressor components.

Interaction with Air and Coolant Systems

The tube is strategically positioned to connect with the compressor air inlet plumbing, allowing for a seamless transition of coolant into the air pathways. This integration ensures that the air being compressed is adequately cooled, enhancing the overall efficiency and performance of the compressor.

Additionally, the tube works in conjunction with the compressor water tube and CPR coolant plumbing to create a closed-loop system. This system ensures that coolant is continuously recirculated, minimizing the risk of leaks and maximizing thermal management within the compressor.

Coordination with Mounting and Drainage Systems

The Compressor Water Outlet Tube is also designed to interface with the mounting and compressor water outlet tube assembly, providing a secure and stable connection point. This ensures that the tube remains firmly in place, even under the dynamic conditions of compressor operation.

Furthermore, the tube is connected to the water drain and water drain tube systems. This connection allows for the efficient removal of any excess water or coolant that may accumulate within the system, preventing potential damage and ensuring the longevity of the compressor components.

Enhanced Thermal Management

By effectively routing coolant through the EBM plumbing and CPR coolant systems, the Compressor Water Outlet Tube plays a significant role in enhancing the thermal management of the compressor. This ensures that all critical components remain within their optimal operating temperature ranges, thereby improving the reliability and performance of the entire system.

Conclusion

In summary, the Compressor Water Outlet Tube, part number 3038036, is a vital component that ensures the efficient circulation and management of coolant within the air compressor system. Its integration with various plumbing and drainage systems underscores its importance in maintaining the overall health and performance of the compressor.

-

Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition, John Dixon, Cengage Learning, 2014.

↩ -

Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Konrad Reif, Springer Vieweg, 2014.

↩ ↩ -

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩ ↩ -

Automotive Systems Principles and Practice, G.K. Awari, V.S. Kumbhar, and R.B. Tirpude, CRC Press, 2011.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.