3042619

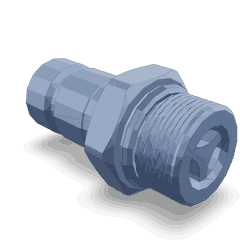

Coupling Nipple

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3042619 Coupling Nipple, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty trucks. This Cummins part is integral to the fluid systems within these vehicles.

Basic Concepts of Coupling Nipples

A coupling nipple is a short pipe fitting used to connect two sections of pipe or other components in a fluid system. Its general function is to facilitate the transfer of fluids, such as hydraulic or fuel, between different parts of the system. In the context of a truck’s hydraulic or fuel system, the coupling nipple ensures a secure and leak-free connection, allowing for the efficient operation of the system 1.

Purpose of the 3042619 Coupling Nipple

The 3042619 Coupling Nipple serves a specific role in the operation of a truck by connecting various components within the system. It is designed to provide a reliable connection point for fluid transfer, ensuring that the system operates smoothly and efficiently. This part is crucial for maintaining the integrity of the fluid pathways within the truck, contributing to overall system performance 2.

Key Features

The 3042619 Coupling Nipple is characterized by several key features that enhance its performance and durability. It is made from high-quality materials, ensuring resistance to corrosion and wear. The design of the nipple includes precise threading and sealing surfaces, which contribute to a secure connection. Additionally, the part may feature unique characteristics such as anti-leak mechanisms or easy-to-use coupling designs, further improving its functionality 3.

Benefits

The advantages of using the 3042619 Coupling Nipple include improved system efficiency and reliability. By providing a secure and leak-free connection, it helps to maintain the integrity of the fluid system, reducing the risk of downtime due to leaks or failures. For fleet operators, this can translate into cost savings through reduced maintenance needs and improved operational efficiency.

Installation and Usage

Proper installation of the 3042619 Coupling Nipple is important to ensure a secure and effective connection. Guidelines for installation may include the use of specific tools to achieve the correct torque and ensure that the coupling is properly aligned. Following these procedures helps to prevent leaks and ensures that the part functions as intended within the system.

Troubleshooting and Maintenance

Common issues that may arise with the 3042619 Coupling Nipple include leaks or connection failures. Identifying these problems early can help to prevent more significant issues down the line. Recommended maintenance practices may include regular inspection of the coupling for signs of wear or damage, and replacing the part if necessary to ensure optimal performance and prolong its lifespan.

Safety Considerations

When working with the 3042619 Coupling Nipple, it is important to observe safety guidelines and precautions. This includes ensuring that the system is depressurized before attempting any work on the coupling, using the correct tools and procedures for installation and maintenance, and following any specific safety instructions provided by the manufacturer.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a range of engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications.

Coupling Nipple 3042619 Compatibility with Cummins Engines

The Cummins Coupling Nipple part number 3042619 is a critical component designed to fit various Cummins engine models. This part is integral in connecting different parts of the engine system, ensuring smooth operation and reliability. Below is a detailed overview of the engines with which this coupling nipple is compatible:

B5.9 and C8.3 Series

- B5.9 GAS PLUS CM556

- C GAS PLUS CM556

- C8.3 G

These engines, part of the B and C series, are designed for gas applications and feature the CM556 and CM876 configurations. The coupling nipple 3042619 fits seamlessly with these engines, providing a robust connection that withstands the operational stresses.

G855 Series

- G855

The G855 engine is another variant that benefits from the coupling nipple 3042619. This part ensures that the engine’s components are securely fastened, enhancing overall performance and longevity.

ISB Series

- ISB5.9G CM2180

- ISB6.7 G CM2180 B118

The ISB series engines, including the ISB5.9G and ISB6.7 G, are known for their versatility and power. The coupling nipple 3042619 is designed to fit these engines, ensuring precise alignment and connection of various engine parts.

ISL and ISM Series

- ISL G CM2180

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

- ISX CM570

- ISX CM870

- ISX CM871

- ISX12 G CM2180 EJ

The ISL and ISM series engines, including the ISX variants, are equipped with the coupling nipple 3042619 to maintain the integrity of their connections. This part is crucial for the proper functioning of these engines, which are widely used in various applications.

L Series

- L GAS PLUS CM556

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

The L series engines, such as the L GAS PLUS CM556 and L10 variants, also utilize the coupling nipple 3042619. This part ensures that the engine’s components are securely connected, contributing to the engine’s overall efficiency and reliability.

M11 Series

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

The M11 series engines, including the CELECT and MECHANICAL variants, are designed for specific applications. The coupling nipple 3042619 fits these engines, ensuring that all parts are properly aligned and connected.

N14 Series

- N14 CELECT

- N14 CELECT PLUS

- N14 MECHANICAL

The N14 series engines, such as the CELECT and MECHANICAL variants, also use the coupling nipple 3042619. This part is essential for maintaining the structural integrity of these engines, ensuring they operate smoothly and efficiently.

Role of Part 3042619 Coupling Nipple in Engine Systems

The 3042619 Coupling Nipple is an essential component in various engine systems, facilitating the connection and efficient transfer of fluids and gases. Its applications span across multiple subsystems, ensuring seamless operation and performance.

Aftercooler Water Plumbing

In the aftercooler water plumbing system, the Coupling Nipple connects the aftercooler to the water supply lines. This ensures that the compressed air is effectively cooled before it enters the engine, enhancing efficiency and reducing the risk of overheating.

Air Intake Manifold Mounting

For the air intake manifold, the Coupling Nipple is used to secure the manifold to the engine block. This connection is vital for maintaining the integrity of the air intake system, ensuring a consistent airflow into the cylinders.

Basic Reconditioning Assembly

During the basic reconditioning of engine assemblies, the Coupling Nipple is employed to reconnect various fluid lines that may have been disconnected during the reconditioning process. This includes oil, coolant, and fuel lines, ensuring that all systems are properly re-established.

Block and Cylinder Short NTC-350

In the engine block and cylinder short NTC-350 configurations, the Coupling Nipple is used to connect the lubricating oil lines. This ensures that the moving parts within the engine receive a continuous supply of oil, reducing friction and wear.

Cooler Lubricating Oil Filter and Lubricating Oil Cooler

The Coupling Nipple plays a significant role in the cooler lubricating oil filter and lubricating oil cooler systems. It connects the oil cooler to the filter, allowing the oil to be cooled and filtered before being recirculated through the engine.

Cylinder Head Conversion Kit

When installing a cylinder head conversion kit, the Coupling Nipple is used to connect the new head to the existing oil and coolant lines. This ensures that the conversion is seamless and that the new head operates efficiently.

Engine Oil and Engine Heater Top Level Assembly Housing

In the engine oil system, the Coupling Nipple connects the oil pump to the various oil galleries within the engine. Additionally, in the engine heater top level assembly housing, it ensures that the heating element is properly connected to the coolant lines.

Engine Oil Cooler and Full Flow Oil Filter

The Coupling Nipple is integral in the engine oil cooler and full flow oil filter systems. It connects the cooler to the oil lines, ensuring that the oil is adequately cooled before it is filtered and recirculated.

Fuel Base Pump and Fuel Pump Adapter

In the fuel system, the Coupling Nipple connects the fuel base pump to the fuel pump adapter, ensuring a consistent fuel supply to the engine. This is essential for maintaining engine performance and efficiency.

Injector Plumbing

For the injector plumbing, the Coupling Nipple connects the fuel injectors to the fuel lines, ensuring that each injector receives the precise amount of fuel needed for combustion.

Lub Oil Cooler and Lubricating Oil Pump

In the lub oil cooler and lubricating oil pump systems, the Coupling Nipple ensures that the oil is properly circulated through the cooler and pump, maintaining optimal oil temperature and pressure.

Pressure Regulator Valve

The Coupling Nipple is used to connect the pressure regulator valve to the fuel or oil lines, ensuring that the system operates within the desired pressure range.

Service Kit & Pump, Lub Oil, Thermostat (Top Level Assembly) Housing

In service kits and pump assemblies, the Coupling Nipple is used to reconnect lub oil lines and thermostat housing, ensuring that all components are properly integrated during maintenance or repair.

Water Pump Arrangement and Water Top Level Assembly Pump

Finally, in the water pump arrangement and water top level assembly pump systems, the Coupling Nipple connects the water pump to the coolant lines, ensuring efficient coolant circulation throughout the engine.

Conclusion

The 3042619 Coupling Nipple is a vital component in the fluid systems of Cummins engines, ensuring secure and efficient connections across various subsystems. Its compatibility with a wide range of Cummins engine models underscores its importance in maintaining the performance and reliability of heavy-duty trucks. Proper installation, regular maintenance, and adherence to safety guidelines are essential to maximize the benefits of this part.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.