3043912

Lockplate

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 4

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3043912 Lockplate is a component designed for use in heavy-duty truck engines and transmissions. It serves a specific function within the mechanical system, contributing to the overall reliability and performance of the vehicle. Understanding its purpose and significance is important for maintaining and repairing heavy-duty trucks.

Basic Concepts of Lockplates

Lockplates are thin, metallic plates used in mechanical systems to secure components in place. They are commonly employed in applications where vibration or movement could loosen parts, potentially leading to mechanical failure. In the context of a truck’s engine or transmission, lockplates help maintain the integrity of connections and ensure that components remain properly aligned and secured 1.

Purpose of the 3043912 Lockplate

This Cummins part plays a role in securing specific components within the engine or transmission system of a truck. Its function is to prevent loosening of fasteners due to vibrations and operational stresses, thereby contributing to the stability and longevity of the mechanical assembly.

Key Features

The 3043912 Lockplate is characterized by its material composition, typically made from high-strength steel to withstand the rigors of heavy-duty applications. Its design includes features such as a bent tab or split ends that grip the fastener, providing a secure hold. These attributes distinguish it from other lockplates, offering enhanced reliability in demanding environments 2.

Benefits

The use of the 3043912 Lockplate offers several advantages. Its robust construction contributes to improved durability, ensuring long-term performance under harsh conditions. Additionally, by securely holding fasteners in place, it enhances the overall efficiency and reliability of the engine or transmission system.

Installation Process

Proper installation of the 3043912 Lockplate involves several steps. First, the fastener should be properly positioned and tightened to the manufacturer’s specifications. The lockplate is then placed over the fastener, with the tab or split ends bent to grip the fastener securely. Tools such as pliers may be required to bend the lockplate into place. It is important to follow best practices to ensure a correct and secure fit 3.

Common Issues and Troubleshooting

Typical problems with the 3043912 Lockplate may include improper installation, leading to insufficient securing of the fastener, or damage to the lockplate itself. Troubleshooting steps involve inspecting the installation for correct placement and grip, and replacing the lockplate if it is damaged or worn.

Maintenance Tips

Regular maintenance of the 3043912 Lockplate involves periodic inspection for signs of wear or damage. Ensuring that fasteners remain securely held by the lockplate is important for the continued reliability of the engine or transmission system. Replacement of the lockplate should be considered if any deterioration is observed.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its high-quality products and innovative solutions in the automotive industry, particularly in the heavy-duty truck sector. The company’s commitment to excellence and customer satisfaction has established it as a trusted name in the field.

Lockplate 3043912 in Cummins Engines

The Lockplate 3043912, manufactured by Cummins, is a critical component in several of their engine models. This part is essential for maintaining the structural integrity and operational efficiency of the engines it fits.

K19 and K38 Engines

The Lockplate 3043912 is designed to fit seamlessly within the K19 and K38 engine series. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The lockplate plays a vital role in securing various engine components, ensuring that they remain in place under high stress and operational conditions.

K50 Engines

Similarly, in the K50 engine series, the Lockplate 3043912 is integral to the engine’s assembly. The K50 engines are engineered for durability and efficiency, making the lockplate a crucial part of their design. It helps in maintaining the alignment and stability of the engine’s internal parts, contributing to the overall longevity and performance of the engine.

QSK19 CM500 Engines

The QSK19 CM500 engines also benefit from the Lockplate 3043912. This engine model is designed for demanding applications, requiring a component that can withstand significant operational stresses. The lockplate ensures that the engine’s components are securely fastened, preventing any misalignment or movement that could lead to performance issues or damage.

Role of Part 3043912 Lockplate in Engine Systems

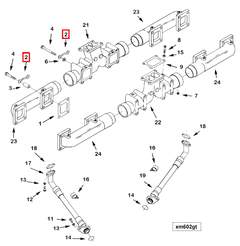

This Cummins part is an integral component in the secure arrangement and mounting of various engine systems. It plays a significant role in ensuring the stability and proper functioning of the following components:

-

Turbocharger: The lockplate is used to secure the turbocharger in its designated location, ensuring it remains fixed during operation. This is essential for maintaining the turbocharger’s efficiency and preventing any movement that could lead to performance issues or damage.

-

Exhaust Manifold: In the context of the exhaust manifold, the lockplate helps in the secure mounting of the manifold to the engine block. This ensures that the exhaust gases are directed efficiently away from the engine, contributing to optimal engine performance and reduced emissions.

-

Exhaust Manifold / Turbocharger Mounting: When connecting the exhaust manifold to the turbocharger, the lockplate provides the necessary stability. It ensures that the connection between these two components is robust, minimizing the risk of leaks or disconnections that could affect engine performance.

-

Exhaust Manifold Mounting Assembly and Kit: The lockplate is often part of the exhaust manifold mounting assembly and kit. It contributes to the overall stability of the exhaust system, ensuring that all components are securely fastened and aligned correctly.

-

Exhaust Mounting Manifold: In various exhaust mounting configurations, whether front, rear, or general, the lockplate plays a role in securing the manifold to the chassis or other structural components. This is vital for maintaining the integrity of the exhaust system and ensuring efficient exhaust gas flow.

-

Exhaust Manifold Mounting: The lockplate is utilized in the exhaust manifold mounting process to ensure that the manifold is correctly positioned and secured. This is important for the proper functioning of the exhaust system and the overall engine performance.

-

Turbocharger Location: When specifying the turbocharger location, the lockplate is used to ensure that the turbocharger is mounted securely in the optimal position. This is important for maximizing turbocharger efficiency and engine performance.

-

Uprate Upper Set: In upgraded engine systems, the lockplate is part of the uprate upper set, contributing to the enhanced stability and performance of the modified components.

Conclusion

Overall, the 3043912 Lockplate is a key component in the secure and efficient arrangement of various engine systems, ensuring that all components are properly mounted and aligned for optimal performance.

-

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Department of Energy. (2015). Department of Energy Fundamentals Handbook. Department of Energy.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.