This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

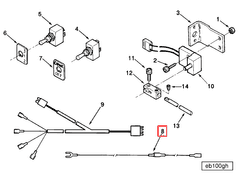

The Cummins 3043934 Wiring Harness is a specialized component designed for commercial trucks. It facilitates the connection between various electrical components and the truck’s power source, ensuring efficient distribution of electrical signals and power throughout the vehicle 1.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals between different vehicle components. It organizes and protects wires, reducing the risk of damage and ensuring reliable performance 2.

Purpose of the 3043934 Wiring Harness

The Cummins 3043934 Wiring Harness is engineered to support the electrical needs of commercial trucks. It integrates with the truck’s engine, transmission, and electronic control units (ECUs), ensuring all electrical components receive the necessary power and signals to function correctly 3.

Key Features

This part is characterized by its robust design and high-quality materials. It is constructed using durable wires and connectors resistant to harsh conditions. The harness features a compact and organized layout, reducing the risk of wire damage and improving the overall reliability of the electrical system. It includes protective coatings and shielding to enhance performance and longevity 4.

Benefits

The use of the Cummins 3043934 Wiring Harness contributes to improved efficiency by ensuring electrical components receive a stable and consistent power supply. It enhances reliability, reducing the likelihood of electrical failures that can lead to downtime. Additionally, it improves safety by preventing electrical shorts and other hazards 5.

Installation Considerations

Proper installation of this Cummins part is important to ensure its effective performance. Installation should be carried out by qualified professionals familiar with commercial truck electrical systems. Special tools or equipment may be necessary to secure the harness and make the necessary electrical connections. Following the manufacturer’s guidelines during installation will help ensure the harness functions as intended 6.

Maintenance and Troubleshooting

Regular maintenance of the 3043934 Wiring Harness is important to ensure its continued performance and reliability. This includes inspecting the harness for signs of wear, damage, or corrosion, and addressing any issues promptly. Basic troubleshooting techniques can identify common problems, such as loose connections or damaged wires, allowing for timely repairs and replacements. Keeping the harness clean and free from debris will also help maintain its efficiency 7.

Safety Precautions

When working with the Cummins 3043934 Wiring Harness, it is important to observe electrical safety practices. This includes ensuring the truck’s battery is disconnected before beginning any work on the electrical system to prevent the risk of electrical shock or short circuits. Handling the harness with care and avoiding sharp objects or excessive force will help prevent damage to the wires and connectors 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes a variety of engines, components, and systems designed to meet the demanding requirements of commercial vehicle applications 9.

Compatibility with Engine Models

The Wiring Harness 3043934 by Cummins is designed to integrate seamlessly with specific engine types, facilitating the transmission of electrical signals necessary for engine operation.

N14 MECHANICAL Engines

For the N14 MECHANICAL engines, this part plays a pivotal role in maintaining the integrity of the electrical connections. This engine model, known for its robust performance and reliability, benefits from the precise and durable wiring harness that ensures all electrical components are properly interconnected. The harness is engineered to withstand the operational stresses of the N14 MECHANICAL engine, providing a stable and efficient electrical pathway 10.

NH/NT 855 Engines

Similarly, the NH/NT 855 engines are designed to work optimally with the Wiring Harness 3043934. This engine series, recognized for its advanced technology and efficiency, relies on the harness to manage the complex electrical demands of the engine. The harness is meticulously crafted to fit the specific electrical architecture of the NH/NT 855, ensuring that all electrical systems are synchronized and functioning as intended. This compatibility is essential for maintaining the high performance and reliability that these engines are known for 11.

Grouping of Engines

The Wiring Harness 3043934 is engineered to be compatible with both the N14 MECHANICAL and NH/NT 855 engines, highlighting its versatility and importance in the overall electrical system of these engines. This compatibility allows for a streamlined installation process and ensures that the electrical systems of these engines are robust and reliable. The harness is designed to meet the specific electrical requirements of each engine model, ensuring that all components are properly connected and functioning efficiently 12.

Role of Part 3043934 Wiring Harness in Engine Systems

The 3043934 Wiring Harness is an integral component in the electrical system of various engine setups, facilitating the connection between multiple subsystems to ensure seamless operation.

In brake systems, the wiring harness interfaces with the brake control module, allowing for the transmission of signals from the cab controls to the brake actuators. This ensures that when a driver engages the brake, the signal is promptly and accurately relayed to the braking mechanism, enabling efficient stopping power.

For engine systems, the wiring harness plays a significant role in connecting the engine control unit (ECU) with various sensors and actuators. It ensures that data from engine sensors, such as temperature, pressure, and oxygen levels, are accurately transmitted to the ECU. This data allows the ECU to make real-time adjustments to fuel injection, ignition timing, and other parameters to optimize engine performance and efficiency.

In combined brake and engine systems, such as those found in the Brake Engine and Cable setups, the wiring harness is responsible for integrating the brake control signals with the engine management system. This integration allows for features like engine braking, where the engine is used to assist in slowing down the vehicle, reducing wear on the traditional braking system.

The wiring harness also connects with the Cable Control Brake and Cable Control Kit, ensuring that manual brake inputs are correctly interpreted and executed by the brake system. This is particularly important in setups where electronic and mechanical brake systems are used in tandem.

In Cummins Engine Brake Kit configurations, the wiring harness is essential for the operation of the engine brake feature. It connects the engine brake actuator with the ECU, allowing for the deployment of engine braking when required, which is especially useful in heavy-duty applications for controlled descents and reduced brake wear.

Lastly, in C Brake (Top Level) Kit, C Brake Kit, C-Brake (444) Kit, and C-Brake Kit systems, the wiring harness ensures that all components of the braking system, whether electronic or mechanical, operate in unison. This is vital for maintaining vehicle stability and safety during braking maneuvers.

Overall, the 3043934 Wiring Harness is a fundamental component that ensures the electrical integrity and functionality of brake and engine systems, contributing to the overall performance, safety, and reliability of the vehicle 13.

Conclusion

The Cummins 3043934 Wiring Harness is a critical component in the electrical systems of commercial trucks, ensuring efficient and reliable operation of various engine and brake systems. Its robust design, compatibility with specific engine models, and integral role in engine and brake system functionality make it an essential part for maintaining vehicle performance and safety.

-

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Martyr, A. J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Quigley, J. M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩ -

Lejda, K., & Wos, P. (2012). Internal Combustion Engines. InTech.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSK19 CM2150 MCRS (Manufactured in India). Bulletin Number 4358453.

↩ -

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Martyr, A. J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Quigley, J. M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for N14 MECHANICAL Engines. Bulletin Number 4358453.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for NH/NT 855 Engines. Bulletin Number 4358453.

↩ -

Cummins Inc. (n.d.). Compatibility Guide for Wiring Harness 3043934. Bulletin Number 4358453.

↩ -

Cummins Inc. (n.d.). Role of Wiring Harness 3043934 in Engine Systems. Bulletin Number 4358453.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.