This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3044442 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital link in the vehicle’s electrical system, facilitating the transmission of electrical power and signals between various components. This harness is integral to the operation of the truck, ensuring that all electrical systems function correctly and efficiently.

Basic Concepts of Wiring Harnesses

A wiring harness is a collection of wires, connectors, and conduits that run throughout a vehicle, transmitting electrical power and signals to various components. It plays a role in the vehicle’s electrical system by providing a structured and organized method for routing wires, which helps prevent electrical interference and ensures reliable connections 1. The importance of a wiring harness lies in its ability to maintain consistent and secure electrical connections, which is vital for the proper operation of all electrical systems in a vehicle.

Purpose of the 3044442 Wiring Harness

The Cummins 3044442 Wiring Harness is specifically designed to integrate with the electrical system of commercial trucks. It connects various electrical components, such as sensors, control modules, and actuators, ensuring that they receive the necessary power and signals to function correctly. This harness plays a role in the overall electrical system by providing a reliable and organized pathway for electrical transmission, which is crucial for the efficient operation of the truck.

Key Features

The Cummins 3044442 Wiring Harness is characterized by several key features that enhance its performance and durability. Its design includes robust connectors and terminals that ensure secure and reliable connections. The materials used in its construction are chosen for their ability to withstand the harsh conditions often encountered in commercial truck environments. Additionally, the harness may include unique characteristics such as protective coatings or specialized routing to further enhance its resilience and functionality.

Benefits

The Cummins 3044442 Wiring Harness offers several advantages. It contributes to improved reliability by ensuring consistent and secure electrical connections throughout the truck’s electrical system 2. This reliability reduces the need for frequent maintenance, as the harness is designed to withstand the rigors of commercial use. Enhanced safety is another benefit, as secure electrical connections help prevent issues such as short circuits or electrical fires, which can pose significant risks in commercial truck operations.

Installation Considerations

Proper installation of the Cummins 3044442 Wiring Harness is vital to ensure its correct and secure fit within the truck’s electrical system. Installation procedures should follow manufacturer guidelines, which may include prerequisites such as preparing the installation area and ensuring all necessary tools are available. Careful attention to detail during installation helps prevent issues such as loose connections or damage to the harness, which could affect the performance of the electrical system.

Troubleshooting Common Issues

Typical problems that may arise with wiring harnesses include loose connections, damaged wires, or faulty connectors. Diagnostic steps to address these issues may involve visual inspections, testing electrical continuity, and using specialized tools to check for proper voltage and signal transmission. Solutions often include repairing or replacing damaged sections of the harness, ensuring all connections are secure, and verifying that the harness is correctly routed to avoid interference or damage.

Maintenance Tips

Routine maintenance practices can help prolong the lifespan and ensure the continued reliable operation of the Cummins 3044442 Wiring Harness. These practices may include regular inspections for signs of wear or damage, cleaning connectors to prevent corrosion, and verifying that all connections remain secure. Additionally, protecting the harness from physical damage and environmental factors can help maintain its integrity and performance over time.

Cummins Overview

Cummins Inc. is a well-established company with a long history in the commercial truck industry. Known for its comprehensive product range, which includes engines, powertrains, and aftermarket parts, Cummins has built a reputation for quality and reliability. The company’s commitment to innovation and customer satisfaction has made it a trusted name in the commercial truck sector, providing solutions that meet the demanding requirements of this industry 3.

Compatibility with Various Engines

The Cummins Wiring Harness part number 3044442 is designed to integrate seamlessly with a variety of engine models. This wiring harness ensures that electrical signals are efficiently transmitted between different parts of the engine, facilitating smooth operation and communication between various engine systems.

K19, K38, and K50 Engines

The K19, K38, and K50 engines are part of Cummins’ range of medium-duty diesel engines, known for their reliability and performance in various applications. The wiring harness 3044442 is engineered to fit these engines by providing a robust and reliable electrical connection. This ensures that the engine’s electronic control unit (ECU) can effectively manage and monitor the engine’s performance, optimizing fuel efficiency and power output.

N14 MECHANICAL and NH/NT 855 Engines

The N14 MECHANICAL and NH/NT 855 engines represent Cummins’ line of heavy-duty diesel engines, widely used in on-highway and vocational applications. The wiring harness 3044442 is specifically designed to interface with these engines, ensuring that all electrical components are properly connected. This is particularly important for maintaining the integrity of the engine’s diagnostic systems, which are critical for detecting and addressing potential issues before they become serious problems.

V28 Engine

The V28 engine is another heavy-duty model in Cummins’ portfolio, known for its durability and high performance. The wiring harness 3044442 is tailored to fit the V28 engine, providing a seamless electrical connection that supports the engine’s complex systems. This ensures that the engine can operate at peak efficiency, with all electrical components functioning as intended.

Each of these engines benefits from the precise engineering of the Cummins Wiring Harness 3044442, ensuring that electrical connections are reliable and robust, supporting the overall performance and longevity of the engine.

Role in Engine Systems

The part 3044442 Wiring Harness is integral to the seamless operation of various engine systems, particularly when interfacing with the generator control panel and main generator instruments.

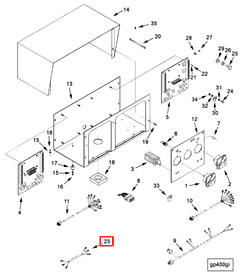

Integration with Generator Control Panel

The wiring harness facilitates the connection between the generator control panel and other electrical components within the engine system. This ensures that power distribution is efficiently managed, allowing the control panel to monitor and regulate the generator’s output. The harness carries signals and power from the control panel to the generator, enabling precise control over voltage and frequency adjustments.

Connection to Main Generator Instruments

For the main generator instruments, the wiring harness serves as the vital link that transmits data and power. It connects gauges, meters, and diagnostic tools to the generator, ensuring that real-time performance metrics are accurately displayed. This allows for continuous monitoring of critical parameters such as voltage, current, and temperature, which are essential for maintaining optimal generator performance and preventing potential failures.

Enhanced System Reliability

By providing a robust and organized pathway for electrical signals and power, the wiring harness enhances the reliability and efficiency of the entire engine system. It reduces the risk of electrical faults and ensures that all components operate in unison, contributing to the overall stability and performance of the generator.

Conclusion

The Cummins 3044442 Wiring Harness is a critical component in the electrical systems of commercial trucks, ensuring reliable and efficient operation of various engine systems. Its robust design, compatibility with multiple engine models, and integration with generator control panels and instruments make it an essential part of maintaining the performance and safety of commercial vehicles.

-

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010.

↩ -

Fundamentals of Vehicle Dynamics and Modelling, Bruce P. Minaker, John Wiley Sons, 2019.

↩ -

Diesel Emissions and Their Control: Second Edition, Addy Majewski and Hannu Jaskelainen, SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.