This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Compressor Water Inlet Tube (Part #3044817) by Cummins is a component designed to facilitate the efficient operation of heavy-duty trucks. This part is integral to the truck’s cooling system, ensuring that the engine operates within optimal temperature ranges. Its role is significant in maintaining the overall performance and longevity of the engine.

Basic Concepts and Functionality

The Compressor Water Inlet Tube operates on the fundamental principle of fluid dynamics within the truck’s cooling system. It directs coolant flow into the compressor, playing a role in dissipating heat generated during engine operation. This tube interacts with other cooling system components, such as the radiator and thermostat, to maintain a consistent coolant temperature 1.

Purpose and Role in Truck Operation

In the context of heavy-duty truck operations, the Compressor Water Inlet Tube serves a specific function. It ensures that the compressor receives a steady supply of coolant, which is vital for maintaining optimal engine temperature. This, in turn, contributes to the engine’s performance by preventing overheating and ensuring efficient operation under various load conditions 2.

Key Features

The Compressor Water Inlet Tube is designed with several key features that enhance its effectiveness and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring longevity. The design includes precise fittings and connections that facilitate easy installation and integration with the truck’s cooling system components.

Benefits

The advantages provided by the Compressor Water Inlet Tube include improved engine efficiency and enhanced durability. By ensuring a consistent coolant flow, it contributes to more stable engine temperatures, which can lead to better fuel efficiency. Additionally, its robust construction offers potential cost savings for fleet operators by reducing the need for frequent replacements 3.

Installation and Integration

Proper installation of the Compressor Water Inlet Tube is crucial for its effective operation. It is designed to be compatible with various truck models, ensuring seamless integration with existing cooling system components. Careful attention to manufacturer guidelines during installation can prevent issues and ensure optimal performance.

Maintenance and Troubleshooting

Maintaining the Compressor Water Inlet Tube is important for ensuring its longevity and optimal performance. Regular inspection procedures should be followed to check for signs of wear or corrosion. Common issues to watch for include leaks or blockages, which can be addressed through routine maintenance checks and timely repairs.

Performance Impact

The Compressor Water Inlet Tube affects the overall performance of the truck by contributing to fuel efficiency, engine longevity, and reliability. By ensuring efficient coolant flow, it helps maintain optimal engine temperatures, which can lead to improved fuel economy and reduced wear on engine components. This results in enhanced reliability under various operating conditions.

Cummins Overview

Cummins Inc. is a well-established company in the automotive industry, known for its high-quality components for heavy-duty trucks. With a history of innovation and a strong reputation for producing reliable parts, Cummins continues to be a trusted name in the industry. Their commitment to quality is evident in the design and construction of components like the Compressor Water Inlet Tube.

Compatibility with Cummins Engines

The Compressor Water Inlet Tube, identified by the part number 3044817, is a critical component in the cooling system of certain Cummins engines. This part is designed to facilitate the flow of water into the compressor, ensuring efficient cooling and optimal performance. Here is a detailed look at its compatibility with various Cummins engines:

N14 CELECT and N14 CELECT PLUS Engines

The N14 CELECT and N14 CELECT PLUS engines are part of Cummins’ lineup of heavy-duty diesel engines. These engines are known for their robust performance and reliability in demanding applications. The Compressor Water Inlet Tube (3044817) is specifically engineered to fit these engines, ensuring that the cooling system operates efficiently. This part is crucial for maintaining the integrity of the engine’s cooling system, preventing overheating, and extending the engine’s lifespan.

N14 MECHANICAL Engines

The N14 MECHANICAL engines are another variant in Cummins’ N-Series engine family. These engines are designed for applications that require a balance of power and efficiency. The Compressor Water Inlet Tube (3044817) is compatible with the N14 MECHANICAL engines, providing a seamless integration into the engine’s cooling system. This ensures that the compressor receives the necessary cooling, which is vital for maintaining performance and reliability.

NH/NT 855 Engines

The NH/NT 855 engines are part of Cummins’ mid-range diesel engine series, known for their versatility and performance in various applications. The Compressor Water Inlet Tube (3044817) is designed to fit these engines, ensuring that the cooling system functions optimally. This part is essential for maintaining the engine’s cooling efficiency, which is critical for preventing overheating and ensuring long-term durability.

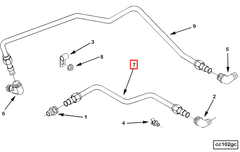

Role of Part 3044817 Compressor Water Inlet Tube in Engine Systems

The Compressor Water Inlet Tube (part 3044817) is integral to the efficient operation of various engine systems, particularly those involving air compressors and compressor coolant arrangements. This component facilitates the precise delivery of water to the compressor, ensuring optimal performance and longevity of the system.

Integration with Air Compressor Systems

In air compressor systems, the Compressor Water Inlet Tube is responsible for channeling water from the water supply to the compressor. This water is essential for cooling the compressor during operation, preventing overheating and potential damage to the compressor components. The tube’s design allows for a steady and controlled flow of water, which is critical for maintaining the compressor’s efficiency and reliability.

Compressor Coolant Arrangement

The Compressor Water Inlet Tube plays a significant role in the compressor coolant arrangement. It ensures that the coolant reaches the compressor in a timely and efficient manner. This is particularly important in high-demand applications where the compressor operates under heavy loads for extended periods. The consistent flow of coolant helps in dissipating heat, thereby protecting the compressor from thermal stress.

Compressor Water Supply and Plumbing

In the context of compressor water supply and plumbing, the Compressor Water Inlet Tube acts as a vital link between the water source and the compressor. Its precise fitting and secure connection are essential for preventing leaks and ensuring that the water supply remains uninterrupted. Proper plumbing with this tube enhances the overall reliability of the water supply system, contributing to the stable operation of the compressor.

Mounting and Stability

The Compressor Water Inlet Tube Mounting is designed to provide a stable and secure connection to the compressor. This stability is essential for withstanding the vibrations and pressures associated with compressor operation. A well-mounted inlet tube ensures that the water supply remains consistent, even under varying operational conditions.

Overall System Efficiency

By ensuring a reliable and consistent water supply, the Compressor Water Inlet Tube contributes to the overall efficiency of the engine system. It supports the compressor’s ability to operate at peak performance, reduces the risk of downtime due to overheating, and enhances the durability of the compressor and associated components.

Conclusion

In summary, the Compressor Water Inlet Tube (part 3044817) is a vital component that ensures efficient cooling in various Cummins engines, including the N14 CELECT, N14 CELECT PLUS, N14 MECHANICAL, and NH/NT 855 engines. Its compatibility with these engines highlights its importance in maintaining the performance and reliability of Cummins’ engine lineup. The part plays a crucial role in the efficient operation of engine systems, particularly in air compressors and compressor coolant arrangements, ensuring optimal performance, efficiency, and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.