This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3046420 Push Rod is a critical component in the valve train system of commercial trucks powered by Cummins engines. This part facilitates the transfer of motion from the camshaft to the rocker arms, which actuate the engine valves. Its precise operation is essential for maintaining the efficiency and performance of the engine.

Basic Concepts of Push Rods

Push rods are mechanical links in internal combustion engines that transmit motion from the camshaft to the valve train components. In overhead valve (OHV) engines, push rods connect the camshaft, located in the engine block, to the rocker arms in the cylinder head. This setup allows the camshaft to control the opening and closing of the valves despite being positioned away from them. Push rods convert the rotational motion of the camshaft into linear motion, which is then used to actuate the valves 1.

Purpose of the Cummins 3046420 Push Rod

The Cummins 3046420 Push Rod is designed to transmit motion from the camshaft to the rocker arms, ensuring the valves open and close at the precise moments required for optimal engine performance. This part interacts with other components such as the camshaft and rocker arms to synchronize valve operation with the engine’s combustion cycle 2.

Key Features

The Cummins 3046420 Push Rod is engineered with specific design and material characteristics to enhance its performance and durability. It features a precise length and diameter tailored to fit within the engine’s valve train system. The push rod may also include special coatings or treatments to reduce friction, increase wear resistance, and improve overall longevity. These features contribute to the reliable operation of the engine under various conditions 3.

Benefits

The Cummins 3046420 Push Rod offers several advantages over other push rod designs. Its precise engineering and high-quality materials contribute to improved engine efficiency, reliability, and longevity. The push rod’s design helps maintain the integrity of the valve train system, ensuring consistent valve operation and contributing to the engine’s overall performance 4.

Installation and Compatibility

Proper installation of the Cummins 3046420 Push Rod is crucial for ensuring optimal engine performance. Installation procedures should follow manufacturer guidelines to avoid issues such as misalignment or excessive wear. Specific requirements or precautions may include ensuring the push rod is properly lubricated and aligned within the engine’s valve train system. Adhering to these guidelines helps maintain the push rod’s performance and durability 5.

Troubleshooting and Maintenance

Common issues with push rods may include wear, bending, or failure due to excessive stress or improper installation. Symptoms of push rod wear or failure can include engine misfires, reduced performance, or unusual noises from the valve train. Regular maintenance practices, such as inspecting push rods for signs of wear and ensuring proper lubrication, can help prolong the life of the Cummins 3046420 Push Rod and maintain engine performance 6.

Performance Enhancements

Modifications or upgrades to the Cummins 3046420 Push Rod can potentially improve engine performance. These may include using aftermarket push rods designed for higher performance applications or making adjustments to the valve train system. Such enhancements can contribute to increased engine efficiency, power output, and overall performance, provided they are implemented correctly and within the engine’s operational limits 7.

Cummins Overview

Cummins Inc. is a renowned manufacturer of diesel engines and components for commercial vehicles. With a history of innovation and quality, Cummins has established a reputation for producing reliable and high-performance engines. The company’s commitment to excellence is reflected in its wide range of products, including the Cummins 3046420 Push Rod, which is designed to meet the demanding requirements of commercial truck engines 8.

Compatibility with Cummins Engines

The Cummins Push Rod 3046420 is designed to fit seamlessly within a variety of Cummins engine models. This part is integral to the operation of the engine, ensuring that the valves function correctly by transferring the motion from the camshaft to the valve train.

G855 and G855 CM558

The Push Rod 3046420 is compatible with the G855 and G855 CM558 engines. These engines are known for their robust design and reliability, often used in heavy-duty applications. The push rod ensures that the valves open and close at the correct times, maintaining the engine’s performance and longevity.

GTA855 CM558 (CM2358) G101

For the GTA855 CM558 (CM2358) G101 engine, the Push Rod 3046420 is a crucial part of the valve train system. This engine variant is designed for high-performance applications, and the push rod’s precision engineering is essential for maintaining the engine’s efficiency and power output.

N14 CELECT and N14 G

The Push Rod 3046420 is also suitable for the N14 CELECT and N14 G engines. These engines are widely used in various industries due to their durability and efficiency. The push rod’s role in these engines is to ensure smooth and reliable valve operation, which is critical for the engine’s overall performance.

N14 MECHANICAL

In the N14 MECHANICAL engine, the Push Rod 3046420 plays a vital role in the mechanical valve train system. This engine is known for its simplicity and ease of maintenance, and the push rod’s design ensures that the valves operate correctly, contributing to the engine’s reliability.

NH/NT 855

Finally, the Push Rod 3046420 is compatible with the NH/NT 855 engine. This engine is designed for heavy-duty applications and requires components that can withstand high stress and frequent use. The push rod’s precision and durability make it an ideal fit for this engine, ensuring that the valve train operates smoothly and efficiently.

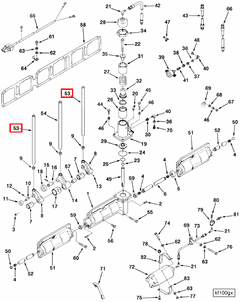

Role of Part 3046420 Push Rod in Engine Systems

The Part 3046420 Push Rod is an integral component in the operation of various engine systems, facilitating the transfer of motion from the camshaft to the valve train. Its function is to transmit the rotational motion of the camshaft to the rocker arms, which in turn actuate the valves. This precise motion transfer is essential for the proper timing of valve opening and closing, which directly impacts engine performance and efficiency.

Interaction with Cylinder Head and Valve Train

Within the cylinder head, the Push Rod connects the cam to the rocker arm. As the camshaft rotates, the cam lobes rise and fall, pushing against the Push Rod. This linear motion is then transferred to the rocker arm, which pivots on its fulcrum to open and close the valves. The accuracy and reliability of this motion are vital for maintaining the engine’s combustion cycle 9.

Integration with EBM: Housing and Lever Mechanisms

In engines equipped with an Electronically Controlled Brake Modulator (EBM), the Push Rod also interacts with the EBM housing and lever mechanisms. The EBM system may use the Push Rod to modulate brake force, requiring the Push Rod to transmit motion with high precision. The lever connected to the EBM housing relies on the Push Rod to ensure smooth and consistent brake application 10.

Coordination with Rocker and Follower Components

The Push Rod works in tandem with rocker and follower components to enhance the engine’s valve operation. The rocker, often a rocker arm, amplifies the cam’s motion, while the follower, typically a roller or flat tappet, makes direct contact with the cam. The Push Rod ensures that the motion from the cam is efficiently transferred to the rocker, allowing for optimal valve lift and duration 11.

Role in Overhaul and Maintenance Kits

In overhaul kits, the Push Rod is often included to ensure that all components of the valve train are in proper working condition. During an engine overhaul, replacing the Push Rod alongside other parts like the rocker arm, cam, and lever ensures that the engine returns to its peak performance standards. The Push Rod’s condition is frequently assessed during maintenance to prevent potential failures in the valve train system 12.

On-Board Spares and Base Parts

For engines designed with on-board spares, the Push Rod is a component that may be stocked for quick replacement in case of failure. This proactive approach to maintenance helps in minimizing downtime. Additionally, the Push Rod is considered a base part in the engine’s design, meaning it is a fundamental component required for the engine’s operation and is often included in the initial assembly of the engine 13.

Conclusion

The Cummins 3046420 Push Rod is a vital component in the valve train system of Cummins engines, ensuring precise and reliable valve operation. Its design and engineering contribute to the overall efficiency and performance of the engine. Proper installation, maintenance, and understanding of its role within the engine system are essential for maximizing the benefits of this part.

-

Automotive Technician Training, Second Edition, Tom Denton and Hayley Pells, Routledge, 2022

↩ -

Engineering Mechanics: Statics, Libby Osgood, Gayla Cameron, and Emma Christensen, Creative Commons, 2024

↩ -

Gasoline Engine Management Systems and Components, Konrad Reif Ed, Springer Vieweg, 2015

↩ -

Dictionary of Mechanical Engineering, D. K. Singh, Springer Nature, 2024

↩ -

X11 CM2670 X126B, Service Manual (5504465)

↩ -

Automotive Technician Training, Second Edition, Tom Denton and Hayley Pells, Routledge, 2022

↩ -

Engineering Mechanics: Statics, Libby Osgood, Gayla Cameron, and Emma Christensen, Creative Commons, 2024

↩ -

Gasoline Engine Management Systems and Components, Konrad Reif Ed, Springer Vieweg, 2015

↩ -

Dictionary of Mechanical Engineering, D. K. Singh, Springer Nature, 2024

↩ -

X11 CM2670 X126B, Service Manual (5504465)

↩ -

Automotive Technician Training, Second Edition, Tom Denton and Hayley Pells, Routledge, 2022

↩ -

Engineering Mechanics: Statics, Libby Osgood, Gayla Cameron, and Emma Christensen, Creative Commons, 2024

↩ -

Gasoline Engine Management Systems and Components, Konrad Reif Ed, Springer Vieweg, 2015

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.