3052218

Injector Spring Retainer

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

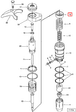

The Cummins Injector Spring Retainer, identified by part number 3052218, is a critical component in the fuel injection system of heavy-duty trucks. It secures the injector spring in place, ensuring the proper functioning of the fuel injection process. This part is essential for maintaining engine efficiency and performance, contributing to the overall reliability of the vehicle.

Function and Operation

The Injector Spring Retainer operates within the fuel injection system by holding the injector spring in the correct position. This ensures that the spring can effectively control the movement of the injector nozzle. When the fuel injection system is activated, the spring’s tension is released, allowing the nozzle to open and deliver fuel into the combustion chamber. The retainer’s precise positioning of the spring is vital for the consistent and accurate operation of the injection system 1.

Purpose of the Injector Spring Retainer

This Cummins part ensures proper fuel injection timing and pressure. By securely holding the injector spring, it allows for the precise control of the injector nozzle’s opening and closing. This precision is important for achieving optimal fuel atomization, which enhances combustion efficiency and contributes to the engine’s performance and fuel economy 2.

Key Features

The design and material characteristics of the Injector Spring Retainer are tailored to enhance its durability and reliability in the demanding environments of truck engines. Typically made from high-strength materials, the retainer is engineered to withstand the high pressures and temperatures within the fuel injection system. Its design ensures a secure fit, minimizing the risk of component failure or misalignment.

Benefits

The advantages provided by the Injector Spring Retainer include improved fuel atomization, which leads to more efficient combustion. This can result in reduced emissions and enhanced engine longevity. The precise control over fuel injection timing and pressure also contributes to the overall performance and efficiency of the engine.

Installation and Compatibility

Proper installation of the Injector Spring Retainer involves ensuring it is correctly positioned and secured within the fuel injection system. Specific requirements or precautions may include verifying the compatibility with the injector nozzle and spring, and ensuring all components are clean and free from debris before installation. Following manufacturer guidelines is important for optimal performance.

Maintenance and Troubleshooting

Routine maintenance practices for the Injector Spring Retainer include regular inspections for signs of wear or damage. Ensuring the component remains clean and free from contaminants is also important. Common troubleshooting tips involve checking for proper seating and alignment, and verifying that the spring tension is within specified parameters. Addressing any issues promptly can help maintain the efficiency and reliability of the fuel injection system.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industries. The company’s extensive product portfolio and commitment to customer satisfaction have made it a preferred choice for professionals in the field.

Cummins Injector Spring Retainer 3052218 Compatibility

The Cummins Injector Spring Retainer part number 3052218 is designed to fit a variety of Cummins engines, ensuring proper function and longevity of the injector system. Here are the engines that this part is compatible with:

Cummins K Series Engines

- K19

- K38

- K50

These engines, part of the K series, are known for their robust design and reliability in various applications. The injector spring retainer is crucial for maintaining the integrity of the injector system in these engines.

Cummins N Series Engines

- N14 MECHANICAL

The N14 MECHANICAL engine is a high-performance engine used in heavy-duty applications. The injector spring retainer ensures that the injectors remain securely in place, contributing to the engine’s overall efficiency and performance.

Cummins QSK Series Engines

- QSK19 CM500

The QSK19 CM500 engine is designed for demanding applications, providing high power output and efficiency. The injector spring retainer is essential for maintaining the precision and reliability of the injector system in this engine.

Cummins NH/NT Series Engines

- NH/NT 855

The NH/NT 855 engine is a versatile option for various industrial applications. The injector spring retainer ensures that the injectors are properly retained, which is vital for the engine’s performance and longevity.

Cummins V Series Engines

- V903

- VTA903 CM2250 V105

The V903 and VTA903 CM2250 V105 engines are part of the V series, known for their power and efficiency. The injector spring retainer is a critical component in these engines, ensuring that the injectors are securely held in place, which is essential for optimal engine performance.

This compatibility ensures that the Cummins Injector Spring Retainer 3052218 can be used across a range of Cummins engines, providing a reliable solution for maintaining the integrity of the injector system.

Role of Part 3052218 Injector Spring Retainer in Engine Systems

The Injector Spring Retainer, identified by part number 3052218, is an essential component in the orchestration of various engine systems. Its primary function is to secure the injector spring within the injector assembly, ensuring consistent and reliable fuel injection.

Integration with Engine Components

-

Cylinder Head Mounting and Injector Assembly: The Injector Spring Retainer works in conjunction with the cylinder head mounting and the injector. It ensures that the injector spring remains in place, allowing for precise fuel delivery into the combustion chamber. This is vital for maintaining engine performance and efficiency.

-

Fuel Connection and EBM Injector: When paired with the fuel connection and EBM injector, the retainer helps maintain the integrity of the fuel injection process. It ensures that the spring, which is responsible for returning the injector plunger to its resting position, functions correctly.

-

Kit On-Board Spares and Service Tool: In maintenance kits such as the kit on-board spares, the Injector Spring Retainer is often included to facilitate quick replacements during servicing. The service tool may be used to install or remove the retainer, highlighting its importance in routine maintenance.

-

Aftercooler and Aftercooler Core: Although the aftercooler and aftercooler core are primarily involved in cooling the compressed air from the turbocharger, the efficient operation of the injector system, supported by the retainer, indirectly affects the overall engine cooling requirements. A well-functioning injector system contributes to optimal engine temperature management.

-

Camshaft and Camshaft and Gear: The timing of fuel injection is often synchronized with the camshaft and camshaft and gear. The Injector Spring Retainer ensures that the injector operates within the precise timing window dictated by the camshaft, enhancing combustion efficiency.

-

Oil Connection and Oil Control Valve: The retainer also plays a role in systems involving oil connections and oil control valves. Proper fuel injection timing and quantity can influence oil consumption and the operation of oil control valves, which manage oil flow to various engine components.

-

Hydro Mechanical Step and Top Stop (Step) Injector: In systems utilizing hydro mechanical steps or top stop (step) injectors, the Injector Spring Retainer ensures that the mechanical components of the injector, including any step mechanisms, function as designed. This is important for engines that require precise fuel metering at different operating conditions.

-

Protective Cover and Cover: The retainer is often housed within a protective cover or a general cover component. This cover shields the injector and its components, including the spring and retainer, from contaminants and physical damage, ensuring longevity and reliable operation.

-

Oil Manifold and Oil Control Valve Mounting Plumbing: The interaction between the injector system and the oil manifold, along with the oil control valve mounting plumbing, relies on the consistent performance of the injector components. The Injector Spring Retainer contributes to this by ensuring the injector spring’s reliable operation.

-

Engine Kit and Performance Parts: In comprehensive engine kits or when upgrading with EBM performance parts, the Injector Spring Retainer is a component that ensures the enhanced injector system performs as expected. It supports the increased demands placed on the fuel injection system by performance modifications.

Conclusion

The Injector Spring Retainer, part 3052218, is a small yet significant component that ensures the reliable operation of the injector system across various engine configurations and enhancements. Its role in securing the injector spring and maintaining precise fuel injection timing and pressure is crucial for engine performance, efficiency, and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.