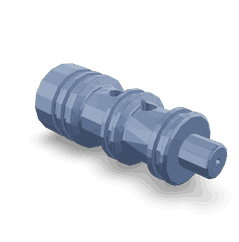

3058944

Pump Tappet Barrel

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Pump Tappet Barrel 3058944, manufactured by Cummins, is a component integral to the operation of heavy-duty truck engines. Cummins, a well-established name in the automotive industry, is renowned for its robust and reliable engine components. This Cummins part plays a significant role in ensuring the efficient functioning of truck engines 1.

Basic Concepts and Functionality

Pump tappet barrels are components within the valve train system of an engine. Their primary role is to transfer motion from the camshaft to the valves, facilitating the opening and closing of the valves in synchronization with the engine’s operation. This transfer of motion is crucial for the intake and exhaust processes, which are fundamental to the engine’s combustion cycle. The pump tappet barrel operates by converting the rotational motion of the camshaft into linear motion, which is then transmitted to the valves. This interaction ensures precise valve timing, which is vital for optimal engine performance 2.

Purpose of the Pump Tappet Barrel 3058944

The Pump Tappet Barrel 3058944 is designed to facilitate the transfer of motion from the camshaft to the valves in Cummins heavy-duty truck engines. By ensuring that the valves open and close at the correct times, it plays a role in maintaining the engine’s combustion efficiency and overall performance. This component is engineered to withstand the high stresses and temperatures encountered in heavy-duty applications, ensuring reliable operation under demanding conditions 3.

Key Features

The Pump Tappet Barrel 3058944 is characterized by its robust design and the use of high-quality materials. It is constructed to endure the rigorous conditions of heavy-duty truck engines, featuring precision machining for accurate fit and function. The material selection ensures durability and resistance to wear, contributing to the component’s longevity and reliability. Additionally, the design of the pump tappet barrel may include features that reduce friction and noise, enhancing the engine’s efficiency and smoothness of operation.

Benefits

The incorporation of the Pump Tappet Barrel 3058944 into Cummins engines offers several benefits. It contributes to improved engine efficiency by ensuring precise valve timing and operation. The durable construction and high-quality materials used in its manufacture reduce wear and tear, leading to enhanced reliability and longevity of the engine components. Furthermore, the design of the pump tappet barrel may include features that minimize friction and noise, contributing to a smoother engine operation.

Installation and Compatibility

Proper installation of the Pump Tappet Barrel 3058944 is crucial for ensuring its optimal performance and longevity. Installation procedures should follow manufacturer guidelines to ensure correct fitment and function. Compatibility with various Cummins engine models is an important consideration, as it ensures that the pump tappet barrel will operate efficiently within the specific engine configuration. Adherence to installation guidelines and compatibility information is vital for maintaining engine performance and reliability.

Maintenance and Troubleshooting

Regular maintenance of the Pump Tappet Barrel 3058944 is essential for ensuring its continued optimal performance. This includes periodic inspection for signs of wear or damage, ensuring proper lubrication, and addressing any issues promptly. Common signs of wear or failure may include unusual noise, leakage, or malfunction in valve operation. Troubleshooting these issues may involve inspecting the pump tappet barrel for damage, ensuring proper clearances, and addressing any lubrication deficiencies.

Performance Enhancements

For those seeking to enhance the performance of their Cummins engine, modifications to the Pump Tappet Barrel 3058944 may be considered. This could include upgrading to materials with higher durability or adjusting clearances for increased efficiency. Such enhancements should be approached with caution and ideally in consultation with a professional to ensure compatibility and effectiveness.

Common Myths and Misconceptions

There are several myths and misconceptions surrounding pump tappet barrels and their function within an engine. It is important to clarify that while they play a role in valve operation, their function is part of a complex system involving multiple components. Regular maintenance and proper installation are key to their effective operation, and misconceptions about their durability or necessity should be addressed with accurate information.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive industry. Their product offerings cater to various sectors, including heavy-duty trucking, construction, agriculture, and power generation, among others. Cummins’ commitment to excellence and customer satisfaction has solidified its position as a leader in the industry.

Cummins Pump Tappet Barrel Part 3058944 Compatibility

The Cummins Pump Tappet Barrel part number 3058944 is a critical component designed to fit seamlessly with a variety of Cummins engines. This part is integral to the proper functioning of the engine’s valve train system, ensuring that the tappets operate smoothly and efficiently.

K-Series Engines

The K19, K38, and K50 engines are part of Cummins’ K-Series line, which are known for their robust design and reliability. The Pump Tappet Barrel part 3058944 is specifically engineered to fit these engines, providing the necessary support and precision for the tappets to function correctly. This ensures optimal performance and longevity of the engine.

L10 MECHANICAL

The L10 MECHANICAL engine is another model where the Cummins Pump Tappet Barrel part 3058944 is compatible. This engine is designed for heavy-duty applications, and the precision of the tappet barrel is crucial for maintaining the engine’s efficiency and durability.

N14 MECHANICAL

Similar to the L10 MECHANICAL, the N14 MECHANICAL engine benefits from the use of the Cummins Pump Tappet Barrel part 3058944. This engine is also used in heavy-duty applications, and the tappet barrel ensures that the valve train operates smoothly, reducing wear and tear and extending the engine’s lifespan.

NH/NT 855

The NH/NT 855 engines are part of Cummins’ mid-range power series, designed for a variety of applications from agricultural to industrial use. The Pump Tappet Barrel part 3058944 is engineered to fit these engines, ensuring that the tappets function correctly and the engine operates efficiently.

V903

The V903 engine is a high-performance model that requires precision components to maintain its efficiency and power. The Cummins Pump Tappet Barrel part 3058944 is designed to fit this engine, providing the necessary support and precision for the tappets to function correctly, ensuring optimal performance and reliability.

Understanding the Role of Part 3058944 Pump Tappet Barrel in Engine Systems

The part 3058944 Pump Tappet Barrel is an integral component in the operation of various engine systems, particularly those involving fuel delivery and management. Its role is to facilitate the precise movement and timing necessary for the efficient functioning of the fuel pump and associated components.

Integration with Fuel Pump Systems

In systems utilizing a Base Fuel Pump or an EBM Pump, the Pump Tappet Barrel works in conjunction with the Fuel Pump Housing to ensure that the Fuel Base is actuated with the correct force and timing. This interaction is vital for maintaining the pressure and flow rate of the fuel, which directly impacts the engine’s performance.

Coordination with Governors

When paired with an American Bosch Governor or a Woodward PSG Governor, the Pump Tappet Barrel helps in modulating the fuel delivery based on the engine’s operational demands. The governor sends signals to the tappet barrel, which then adjusts the fuel pump’s operation to match the engine’s speed and load conditions.

Role in Fuel Injection Systems

In engines equipped with Fuel Injection systems, the Pump Tappet Barrel ensures that the fuel is delivered at the precise moment required for optimal combustion. This is achieved by synchronizing the tappet barrel’s movements with the engine’s camshaft, ensuring that the fuel is injected into the combustion chamber at the exact right time.

Interaction with Aftercooler Assembly

In systems that include an Aftercooler Assembly, the Pump Tappet Barrel’s role extends to ensuring that the fuel delivered is at the optimal temperature and pressure. This is particularly important in high-performance or high-stress engine environments where fuel temperature can significantly affect engine efficiency and reliability.

Coupling and Drive Mechanisms

The Pump Tappet Barrel also interacts with the Coupling and Fuel Pump and Drive mechanisms. It ensures that the mechanical energy from the engine’s camshaft is efficiently transferred to the fuel pump, allowing for consistent and reliable fuel delivery.

Summary of Component Interactions

- Base Fuel Pump and EBM Pump: Ensures correct actuation force and timing.

- Fuel Pump Housing and Fuel Base: Maintains pressure and flow rate.

- American Bosch Governor and Woodward PSG Governor: Modulates fuel delivery based on engine demands.

- Fuel Injection Systems: Synchronizes fuel delivery with engine camshaft.

- Aftercooler Assembly: Ensures optimal fuel temperature and pressure.

- Coupling and Fuel Pump and Drive: Transfers mechanical energy efficiently.

Understanding these interactions highlights the importance of the Pump Tappet Barrel in ensuring the smooth and efficient operation of engine systems.

Conclusion

The Pump Tappet Barrel 3058944 is a critical component in Cummins heavy-duty truck engines, ensuring precise valve timing and efficient engine operation. Its robust design, compatibility with various Cummins engine models, and role in fuel delivery systems underscore its importance in maintaining engine performance and reliability. Regular maintenance and proper installation are essential for maximizing the benefits of this component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.