This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

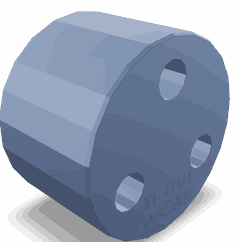

The Cummins 3062904 Idler Shaft is a critical component in heavy-duty truck engines, designed to enhance engine efficiency and reliability. Understanding its function and importance is essential for maintaining and optimizing the performance of these engines.

Basic Concepts of Idler Shafts

An idler shaft is a mechanical component used to change the direction of a rotating drive belt or chain. In engines, it maintains the proper tension and alignment of timing belts or chains, ensuring synchronized operation of the camshaft and crankshaft. This synchronization is crucial for the engine’s performance, affecting how air and fuel are mixed and combusted within the cylinders 1.

Role of the 3062904 Idler Shaft in Truck Engines

The Cummins 3062904 Idler Shaft is vital for the timing system in truck engines. It interacts with the timing belt or chain, camshaft, and crankshaft to ensure precise valve timing. This precision directly influences the engine’s efficiency and durability by maintaining the correct tension and alignment of the timing components 2.

Key Features of the 3062904 Idler Shaft

This Cummins part is characterized by high-quality materials and precise machining, ensuring smooth operation and compatibility with other engine components. It may include features like a built-in tensioner or specific bearing configurations to enhance functionality and longevity 3.

Benefits of Using the 3062904 Idler Shaft

Utilizing this part in truck engines offers advantages such as improved engine efficiency through minimal friction and maximum precision in timing components. Its durable construction reduces the likelihood of engine failures, contributing to increased engine lifespan. Additionally, it enhances the overall reliability of the engine by maintaining proper timing belt or chain tension 4.

Installation and Integration

Installing the 3062904 Idler Shaft requires careful alignment with the timing belt or chain and securing it according to manufacturer specifications. Special tools may be necessary to achieve the correct tension and alignment, ensuring the idler shaft functions as intended within the engine system.

Common Issues and Troubleshooting

Common issues with the 3062904 Idler Shaft include wear and tear, misalignment, or tensioner mechanism failure. Diagnostic methods involve inspecting for damage or excessive wear and checking the tension and alignment of timing components. Solutions may range from adjusting tension to replacing worn parts to ensure effective operation.

Maintenance Practices

Maintaining the 3062904 Idler Shaft is crucial for its longevity and performance. Recommended practices include regular inspections for wear or damage, ensuring proper lubrication of moving parts, and following manufacturer guidelines for replacement intervals. Adhering to these routines helps prevent unexpected failures and ensures efficient engine operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader known for its quality, innovation, and reliability in the commercial truck industry. Its product range is designed to meet the demanding requirements of heavy-duty applications, ensuring optimal performance and durability.

Compatibility of Idler Shaft Part 3062904 with Cummins Engines

The Idler Shaft part 3062904 is designed to fit seamlessly with various Cummins engines, ensuring smooth operation and reliability across different models. It is integral to the engine’s functionality, providing necessary support and alignment for other components.

ISM Series Engines

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

L10 Series Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

M11 Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

QSM11 Series Engines

- QSM11 CM570

- QSM11 CM876

Role of Part 3062904 Idler Shaft in Engine Systems

The idler shaft, designated as part 3062904, is integral to the engine’s valve train mechanism. Its primary function is to maintain proper tension on the valve timing components, ensuring synchronized operation between the camshaft and crankshaft. Positioned between the camshaft and the cylinder block, it plays a significant role in the distribution of rotational force. This shaft helps in adjusting the valve timing by altering the position of the camshaft relative to the crankshaft. Additionally, it contributes to the reduction of wear and tear on other engine components by maintaining consistent tension, preventing excessive movement and potential damage to the timing chain or belt. This enhances the durability and reliability of the engine. Furthermore, the idler shaft assists in the efficient transfer of power from the crankshaft to the camshaft, ensuring that the valves open and close at the precise moments required for optimal engine performance. The synchronization provided by the idler shaft is essential for maintaining the engine’s efficiency and power output 5.

Conclusion

In summary, the 3062904 Idler Shaft is a key element in the engine’s valve train system, contributing to the precise timing and efficient operation of engine components. Its role in maintaining tension and alignment of timing components directly influences the engine’s efficiency, durability, and overall performance.

-

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Carroll, Douglas R. Energy Efficiency of Vehicles. SAE International, 2020.

↩ -

Ribbens, William B. Understanding Automotive Electronics. Elsevier Science, 2003.

↩ -

Goodnight, Nicholas and VanGelder, Kirk. Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning, 2019.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 2883641.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.