This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

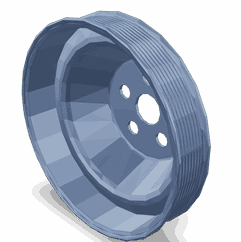

Introduction To The Crankshaft Pulley

A crankshaft pulley, also known as a harmonic balancer, is a vital component in the engine of a commercial truck. This part is responsible for transmitting power from the engine’s crankshaft to various engine accessories such as the alternator, water pump, and air conditioning compressor. The crankshaft pulley is typically bolted to the front of the crankshaft and rotates at the same speed as the engine, ensuring that all connected accessories receive the necessary power to function correctly 1.

The Role Of The Cummins 3073676 Crankshaft Pulley

The Cummins 3073676 crankshaft pulley is specifically engineered for use in heavy-duty trucks and commercial vehicles. Its primary function is to ensure that the various engine accessories receive the necessary power to operate efficiently. Additionally, the crankshaft pulley plays a crucial role in maintaining the balance of the rotating assembly, which helps to reduce vibrations and ensures smooth engine operation. This balance is critical in heavy-duty applications where engine stress and load are significantly higher than in standard vehicles 2.

How The Cummins 3073676 Crankshaft Pulley Works

The Cummins 3073676 crankshaft pulley operates by converting the reciprocating motion of the pistons into rotational motion. This conversion is achieved through the use of a harmonic balancer, which is a rubber-metal composite designed to absorb and dampen vibrations. The crankshaft pulley is securely bolted to the front of the crankshaft and rotates in sync with the engine. As it rotates, it transmits power to the various engine accessories, ensuring they function correctly. The harmonic balancer within the pulley is crucial for absorbing vibrations that could otherwise lead to engine imbalance and increased wear on components 3.

Importance Of The Cummins 3073676 Crankshaft Pulley In Truck Operations

The crankshaft pulley is indispensable in the operation of a commercial truck. It ensures that essential engine accessories receive the power they need to function, which is vital for the smooth and efficient operation of the engine. A faulty crankshaft pulley can lead to a host of issues, including engine misfires, reduced power output, and increased wear and tear on engine components. These issues can result in costly repairs and downtime, making the crankshaft pulley a component that demands attention and care.

Troubleshooting And Maintenance Of The Cummins 3073676 Crankshaft Pulley

Regular maintenance and troubleshooting of the crankshaft pulley are essential to ensure the smooth operation of the engine. Common issues that can arise with the crankshaft pulley include wear and tear, cracking, and misalignment. These problems can often be identified through regular inspections. Signs of wear may include visible cracks on the pulley or excessive play when the engine is running. Addressing these issues promptly through maintenance and repairs can prevent more severe problems down the line. It is also important to ensure that the pulley is properly aligned and securely bolted to the crankshaft to maintain optimal engine performance.

Cummins: A Leader In Commercial Truck Parts

Cummins is a renowned manufacturer of commercial truck parts, including the Cummins 3073676 crankshaft pulley. The company is widely respected for its commitment to quality, reliability, and innovation. Cummins’ dedication to research and development ensures that its products are at the cutting edge of technology, providing commercial truck operators with the best possible performance and reliability. The Cummins 3073676 crankshaft pulley is no exception, offering superior quality and durability that truck operators can rely on.

Crankshaft Pulley 3073676 Compatibility with Cummins Engines

The Crankshaft Pulley part number 3073676, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral to the engine’s operation, ensuring the smooth transfer of power from the crankshaft to the engine’s accessories.

ISM Series Engines

- ISM CM570

- ISM CM570/870

- ISM11 CM876 SN

The ISM series engines, including the ISM CM570, ISM CM570/870, and ISM11 CM876 SN, are equipped with the 3073676 crankshaft pulley. This part is crucial for these engines, facilitating the operation of the alternator, water pump, and other essential components.

L10 Series Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

The L10 series engines, such as the L10 CELECT, L10 GAS, and L10 MECHANICAL, also utilize the 3073676 crankshaft pulley. This part ensures that the engine’s accessories receive the necessary power to function correctly, maintaining the engine’s overall efficiency and performance.

M11 Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

The M11 series engines, including the M11 CELECT, M11 CELECT PLUS, and M11 MECHANICAL, are compatible with the 3073676 crankshaft pulley. This part is essential for these engines, ensuring that the crankshaft’s rotational energy is effectively transferred to the engine’s accessories.

QSM11 Series Engines

- QSM11 CM570

- QSM11 CM876

The QSM11 series engines, such as the QSM11 CM570 and QSM11 CM876, also use the 3073676 crankshaft pulley. This part is vital for these engines, ensuring that the crankshaft’s power is efficiently transmitted to the engine’s accessories, maintaining the engine’s operational integrity.

Role of Part 3073676 Crankshaft Pulley in Engine Systems

The Part 3073676 Crankshaft Pulley is an integral component in the synchronization and efficient operation of various engine systems. It serves as the primary driver for multiple auxiliary components, ensuring they operate in harmony with the engine’s rotational motion.

Integration with the Damper

The Crankshaft Pulley is directly connected to the engine’s crankshaft, where it interfaces with the damper. The damper’s role is to absorb and mitigate the torsional vibrations generated by the engine’s operation. As the Crankshaft Pulley rotates, it transfers the crankshaft’s motion to the damper, which then smooths out these vibrations. This results in a more stable and consistent rotational force being transmitted to the other engine components, enhancing overall engine performance and longevity.

Interaction with Vibration Control Systems

In addition to its connection with the damper, the Crankshaft Pulley also plays a significant role in the engine’s vibration control systems. By maintaining a steady and uniform rotational speed, it helps in reducing the overall vibration levels within the engine. This is particularly important in high-performance engines where even minor vibrations can lead to decreased efficiency and increased wear on components. The consistent motion provided by the Crankshaft Pulley ensures that the vibration control systems can effectively do their job, leading to a smoother and more reliable engine operation.

Synergy with Auxiliary Components

Furthermore, the Crankshaft Pulley is the driving force behind several auxiliary components such as the alternator, power steering pump, and air conditioning compressor. As it rotates, it drives these components through a series of belts or chains, ensuring they receive the necessary power to function. This seamless transfer of motion is essential for the proper operation of these systems, which in turn support the engine’s overall performance and the vehicle’s drivability.

Conclusion

The Cummins 3073676 crankshaft pulley is a critical component in the operation of a commercial truck. Its role in transmitting power to various engine accessories and maintaining the balance of the rotating assembly is indispensable. Regular maintenance and troubleshooting are essential to ensure the smooth operation of the engine and to prevent costly breakdowns and repairs. With its reputation for quality, reliability, and innovation, Cummins continues to be a trusted name in the industry, providing commercial truck operators with the best possible performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.