This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3077718 Injector is a critical component for commercial trucks, essential for the efficient operation of these vehicles. This part is integral to the fuel system, responsible for delivering fuel into the engine’s combustion chambers. Its proper function is crucial for maintaining engine performance and efficiency.

Basic Concepts of Fuel Injectors

Fuel injectors are devices used in internal combustion engines to deliver fuel into the combustion chamber. They operate by spraying atomized fuel into the air intake, where it mixes with air and ignites during the combustion process. The precise control of fuel delivery by injectors is crucial for optimizing engine performance, fuel efficiency, and emissions 1.

Role of the 3077718 Injector in Truck Operation

The Cummins 3077718 Injector ensures accurate and timely fuel delivery to the engine. This injector is engineered to work under the high pressures and temperatures found in diesel engines, providing a fine mist of fuel that enhances combustion efficiency. Its role in the fuel delivery system directly impacts the engine’s power output, fuel economy, and emissions levels.

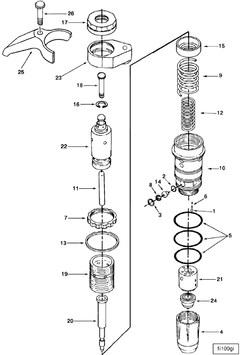

Key Features of the 3077718 Injector

The Cummins 3077718 Injector is characterized by its robust design and the use of high-quality materials, ensuring durability and reliability in demanding conditions. It incorporates advanced technological features such as precision nozzles and electronic control mechanisms, which allow for fine-tuning of fuel delivery. These features contribute to the injector’s ability to maintain performance standards over time 2.

Benefits of Using the 3077718 Injector

Utilizing the Cummins 3077718 Injector in commercial trucks offers several advantages. It enhances fuel efficiency by ensuring that fuel is delivered in the most effective manner possible. This injector also contributes to improved engine performance, providing consistent power output and smooth operation. Additionally, its reliable design helps in reducing maintenance needs and extending the engine’s lifespan 3.

Troubleshooting Common Issues with the 3077718 Injector

Common issues with the Cummins 3077718 Injector may include clogging, leaks, or malfunctions in the electronic control system. Identifying these problems early can prevent more significant engine issues. Solutions may involve cleaning the injector, replacing worn-out components, or recalibrating the electronic controls. Regular maintenance and inspections are recommended to address potential issues before they escalate 4.

Maintenance Tips for the 3077718 Injector

To ensure the optimal performance and longevity of the Cummins 3077718 Injector, regular maintenance is advised. This includes periodic inspections for signs of wear or damage, cleaning the injector to remove any deposits, and ensuring that the electronic controls are functioning correctly. Following the manufacturer’s guidelines for maintenance intervals and procedures can help maintain the injector’s efficiency and reliability.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. The company’s product offerings cater to various sectors, including commercial vehicles, construction, agriculture, and power generation, among others.

Interaction with Fuel System Components

The 3077718 Injector works in concert with the fuel pump, fuel rail, and fuel pressure regulator to maintain consistent fuel pressure. It receives pressurized fuel from the fuel rail and, upon receiving an electrical signal from the engine control unit (ECU), atomizes the fuel into a fine mist. This process enhances fuel efficiency and reduces emissions.

Contribution to Engine Performance

In performance-oriented engine systems, the 3077718 Injector is often paired with high-flow fuel pumps and upgraded fuel lines to handle increased fuel demands. The injector’s ability to deliver fuel quickly and accurately directly influences engine responsiveness and power output.

Integration with Engine Control Unit (ECU)

The ECU plays a significant role in the operation of the 3077718 Injector. It monitors various engine parameters such as throttle position, engine speed, and air intake temperature. Based on this data, the ECU sends precise timing signals to the injector, ensuring that fuel delivery is synchronized with the engine’s operational needs.

Compatibility with Aftermarket Performance Parts

When upgrading to performance parts such as cold air intakes, turbochargers, or nitrous oxide systems, the 3077718 Injector must be capable of handling the increased fuel load. Properly matched injectors ensure that the engine receives the necessary fuel to support higher power outputs without risking detonation or lean conditions.

Role in Emission Control Systems

The 3077718 Injector also interacts with emission control components like the oxygen sensors and catalytic converter. Accurate fuel delivery helps maintain the proper air-fuel ratio, which is essential for the efficient operation of these systems. This, in turn, ensures that the engine meets emissions standards and operates cleanly.

Conclusion

The Cummins 3077718 Injector is a vital component in the efficient operation of commercial trucks. Its role in delivering precise fuel into the combustion chamber directly impacts engine performance, fuel efficiency, and emissions. Regular maintenance and proper integration with the engine control unit and other fuel system components are essential for ensuring the longevity and reliability of this Cummins part.

-

Konrad Reif, Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Springer Vieweg, 2014.

↩ -

Harald Naunheimer, Bernd Bertsche, Joachim Ryborz, Wolfgang Novak, Automotive Transmissions Fundamentals Selection Design and Application, Springer Vieweg, 2011.

↩ -

Douglas R Carroll, Energy Efficiency of Vehicles, SAE International, 2020.

↩ -

Ben Watson, Mobile Equipment Hydraulics A Systems and Troubleshooting Approach, Cengage Learning, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.