This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

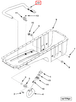

The Lubricating Oil Suction Tube, identified by part number 3095051, is a component manufactured by Cummins. This tube is integral to the lubrication system of heavy-duty trucks. It ensures the efficient circulation of lubricating oil within the engine, contributing to the overall performance and longevity of the engine 1.

Function and Operation

The Lubricating Oil Suction Tube operates by drawing oil from the sump, the lowest part of the engine where oil collects, and delivering it to the oil pump. This process is vital for maintaining a consistent supply of oil to the engine’s moving parts, ensuring they are adequately lubricated to reduce friction and wear 2. The tube’s design allows for a smooth and uninterrupted flow of oil, which is crucial for the engine’s lubrication system to function effectively.

Key Features

The Lubricating Oil Suction Tube is constructed from high-quality materials, ensuring durability and resistance to the harsh conditions within an engine compartment. Its design includes a specific tube diameter that optimizes oil flow while minimizing the risk of air ingestion, which can lead to inefficient lubrication 3. Unique design elements may include reinforced sections to withstand pressure fluctuations and a smooth interior to facilitate oil movement.

Benefits

The advantages of the Lubricating Oil Suction Tube include improved oil flow, which ensures that engine components receive a steady supply of lubricant. This consistent flow helps in reducing the risk of air ingestion into the lubrication system, which can cause cavitation and reduce the efficiency of oil delivery. Enhanced engine lubrication efficiency leads to better engine performance and longevity, as critical components are protected from excessive wear and heat 4.

Installation and Compatibility

Proper installation of the Lubricating Oil Suction Tube is crucial for its effective operation. It should be securely fitted within the engine compartment, following manufacturer guidelines to ensure a snug and leak-free connection. Specific requirements may include the use of gaskets or seals to prevent oil leaks and ensure a secure fit. Compatibility with the engine model is essential to maintain the integrity of the lubrication system 5.

Maintenance and Troubleshooting

Routine maintenance of the Lubricating Oil Suction Tube involves regular inspections for signs of wear, leaks, or blockages. Cleaning the tube and ensuring it is free from debris can help maintain optimal performance. Troubleshooting common issues such as leaks may involve checking connections and seals for integrity, while blockages can be addressed by ensuring the tube is clear of obstructions. Regular maintenance helps in identifying potential issues before they lead to more significant problems 6.

Cummins Overview

Cummins is a well-established manufacturer in the automotive industry, known for its high-quality engine components. With a rich history of innovation and a broad range of product offerings, Cummins has built a reputation for reliability and performance. Their expertise in engine technology is reflected in the design and manufacturing of components like the Lubricating Oil Suction Tube, ensuring they meet the demanding requirements of heavy-duty applications 7.

Compatibility with Cummins Engines

The Cummins part 3095051, a Lubricating Oil Suction Tube, is designed to fit seamlessly within a range of Cummins engine models. This part is integral to the engine’s lubrication system, ensuring that oil is efficiently drawn from the oil pan and circulated throughout the engine to reduce friction and wear.

For the G855 and G855 CM558 engines, the 3095051 part is engineered to integrate with the engine’s design, providing a reliable pathway for oil suction. Similarly, for the GTA855 CM558 (CM2358) G101, this component is crafted to match the specific requirements of the engine’s architecture.

In the case of the N14 series engines, including the N14 CELECT, N14 CELECT PLUS, N14 G, and N14 MECHANICAL, the 3095051 part is tailored to fit these models, ensuring optimal oil flow and system integrity. The same applies to the NH/NT 855 engine, where this part is designed to work in harmony with the engine’s design.

Lastly, for the QSN14 CM876 N103 engine, the 3095051 part is specifically engineered to meet the unique demands of this engine model, ensuring that the oil suction process is both efficient and reliable.

Role of Part 3095051 Lubricating Oil Suction Tube in Engine Systems

The lubricating oil suction tube, identified as part 3095051, is integral to the efficient operation of engine systems. This component facilitates the smooth transfer of oil from the oil pan to the engine’s lubrication system.

In the context of the Engine Block Module (EBM), the suction tube works in conjunction with the oil pan to ensure a consistent oil supply. The oil pan, often part of an oil pan kit, stores the engine oil and is designed to provide a stable base for the suction tube. As the engine operates, the suction tube draws oil from the pan, which is then circulated through the engine by the oil pump.

The design of the oil pan and the placement of the suction tube are engineered to minimize aeration of the oil, which can lead to inefficient lubrication. The tube’s connection to the oil pan is secure, ensuring that oil is drawn from the lowest point of the pan, where the oil is typically at its coolest and least contaminated state.

The integration of the suction tube with the oil pan kit is a testament to the meticulous engineering that goes into maintaining optimal engine performance. The kit often includes gaskets and seals that ensure a leak-free connection between the pan and the suction tube, further enhancing the reliability of the lubrication system.

Conclusion

In summary, the lubricating oil suction tube plays a significant role in the engine’s lubrication circuit, working hand-in-hand with the oil pan and other components to deliver a steady flow of oil to the engine’s moving parts. Proper installation, maintenance, and understanding of its function are crucial for ensuring the longevity and efficiency of the engine.

-

{ title : Diesel Engines , author : A. J. Wharton , publisher : Butterworth-Heinemann Ltd , date : 1991 }

↩ -

{ title : Diesel Mechanics, First Edition , author : Frank Sander , publisher : Global Media , date : 2007 }

↩ -

{ title : Dictionary of Mechanical Engineering , author : D. K. Singh , publisher : Springer Nature , date : 2024 }

↩ -

{ engine : B6.7 CM2350 B135B , bulletinNumber : Bulletin Number 5411258 , title : Operation and Maintenance Manual }

↩ -

{ engine : B6.7 CM2350 B135B , bulletinNumber : Bulletin Number 5411258 , title : Operation and Maintenance Manual }

↩ -

{ engine : B6.7 CM2350 B135B , bulletinNumber : Bulletin Number 5411258 , title : Operation and Maintenance Manual }

↩ -

{ engine : B6.7 CM2350 B135B , bulletinNumber : Bulletin Number 5411258 , title : Operation and Maintenance Manual }

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.