This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Cummins’ 3170783 Wiring Harness is a specialized component designed for commercial trucks, integral to the vehicle’s electrical system. This part facilitates the efficient and safe operation of electrical components by providing organized and protected pathways for electrical wires 3.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays, bundled together to transmit electrical power and signals throughout a vehicle. It consists of various components, including wires of different gauges, connectors, terminals, and protective sheathing. The primary function of a wiring harness is to ensure that electrical signals and power are distributed efficiently and safely to all parts of the vehicle that require them 2.

Purpose of the 3170783 Wiring Harness

This Cummins part is specifically designed to facilitate the connection between various electrical components within a truck and the vehicle’s power source. It provides a structured and protected pathway for electrical signals and power, ensuring that components such as lights, sensors, and control units receive the necessary electrical input for operation 3.

Key Features

The 3170783 is characterized by its robust design and the quality of materials used in its construction. It is built to withstand the demanding conditions typical of commercial truck operations, featuring durable wires, high-quality connectors, and protective sheathing. These features enhance its performance and durability, making it suitable for heavy-duty applications 1.

Benefits

Utilizing this part in commercial trucks offers several advantages. It contributes to improved electrical efficiency by ensuring that power and signals are transmitted with minimal loss. The design reduces the risk of short circuits and other electrical faults, enhancing the safety and reliability of the truck’s electrical system. Additionally, its durability ensures long-term performance under the rigorous conditions encountered in commercial truck operations 3.

Installation Considerations

When installing the 3170783, it is important to consider compatibility with the specific truck model and to follow the manufacturer’s recommendations. Proper installation is crucial for ensuring the harness functions as intended, providing reliable electrical connections and protecting the wires from damage. Adhering to these guidelines helps maintain the integrity of the vehicle’s electrical system 2.

Troubleshooting and Maintenance

Common issues with wiring harnesses, such as electrical faults or connectivity problems, can often be traced back to installation errors or environmental damage. Regular inspection and maintenance of the 3170783 can help identify potential issues before they lead to more significant problems. Maintenance tips include checking for signs of wear or damage, ensuring all connections are secure, and protecting the harness from physical damage and exposure to harsh elements 1.

Safety Precautions

Working with electrical components, including the 3170783, requires observing certain safety precautions. Electrical safety practices, such as ensuring the vehicle’s battery is disconnected before working on the harness, are crucial. Proper handling and storage of the harness are also important to prevent damage and ensure its longevity. Adhering to these safety measures helps protect both the technician and the vehicle’s electrical system 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, related technologies, and complete power systems. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the automotive industry. The company’s focus on quality and innovation is evident in its products, including the 3170783, which is designed to meet the high standards required for commercial truck applications 3.

Compatibility

The 3170783 is designed to integrate seamlessly with a variety of engine models, ensuring reliable electrical connectivity and performance. This wiring harness is engineered to meet the specific needs of the engines it supports, providing a robust and efficient solution for managing electrical systems.

K50 Series

For the K50 series engines, the Wiring Harness 3170783 is meticulously crafted to fit the unique electrical architecture of these engines. The harness is designed to connect various electrical components, ensuring that power and signals are transmitted accurately and efficiently. This compatibility is crucial for maintaining the operational integrity of the engine, as it supports critical functions such as ignition, fuel delivery, and emissions control.

The harness is constructed with high-quality materials that are resistant to wear and environmental factors, ensuring longevity and reliability. Its design allows for easy installation and maintenance, reducing downtime and enhancing overall engine performance. The precise fit and robust construction of the harness make it an essential component for the K50 series engines, facilitating smooth and efficient operation 3.

Role of Part 3170783 Wiring Harness in Engine Systems

The Part 3170783 Wiring Harness is an essential component that facilitates the electrical connections required for various engine systems. Its role is to ensure reliable and efficient communication between different electrical components, thereby enhancing the overall performance and functionality of the engine.

Integration with 12V and 24V Valve/Electric Kits

In both the 12V and 24V valve/electric kits, the Wiring Harness 3170783 plays a pivotal role. It provides the necessary electrical pathways for the valves to operate correctly. This includes connecting the valves to the engine’s control module, ensuring that signals are transmitted accurately and promptly. The harness also supports the electric components within these kits, allowing for precise control over valve operations, which is vital for maintaining engine efficiency and performance 3.

Centinel Make-Up and Pressure-Time Systems

For the Centinel Make-Up Kit and the N14 12V Pressure-Time Centinel Kit, the Wiring Harness 3170783 ensures that the make-up and pressure-time systems receive the correct electrical signals. This is important for maintaining the proper oil levels and pressure within the engine, which are critical for lubrication and overall engine health. The harness connects these systems to the engine’s control unit, allowing for real-time monitoring and adjustments 3.

HHP 12V and 24V Valve/Electric Kits

In the HHP 12V and 24V Valve/Electric Kits, the Wiring Harness 3170783 is responsible for linking the high-pressure pump (HHP) to the engine’s electrical system. This connection is essential for the pump to operate efficiently, ensuring that the engine receives the necessary fuel pressure for optimal performance. The harness also supports the electric components, facilitating smooth and reliable operation of the HHP system 3.

QKS Valve & Mounting and Multiple Key-Off Kit

The QKS Valve & Mounting Kit and the Multiple Key-Off Kit rely on the Wiring Harness 3170783 to establish the electrical connections needed for their operation. The QKS valve requires precise electrical signals to function correctly, while the Multiple Key-Off Kit needs reliable connections to ensure that all components shut down properly when the engine is turned off. The harness provides these connections, enhancing the safety and efficiency of these systems 3.

N14 24V Hardware-Pressure-Time Valve/Mounting Kit

In the N14 24V Hardware-Pressure-Time Valve/Mounting Kit, the Wiring Harness 3170783 ensures that the pressure-time valve receives the necessary electrical signals to operate within specified parameters. This is vital for maintaining the correct oil pressure and timing, which are essential for the engine’s longevity and performance. The harness also supports the mounting kit’s electrical components, ensuring that all parts work in unison 3.

Oil Replenishing System

Finally, the Wiring Harness 3170783 is integral to the oil replenishing system. It provides the electrical connections needed for the system to monitor oil levels and replenish them as required. This ensures that the engine always has the necessary lubrication, reducing wear and tear and enhancing overall engine reliability 3.

Conclusion

The Part 3170783 Wiring Harness is a fundamental component that ensures the proper functioning of various engine systems by providing essential electrical connections and pathways. Its role in facilitating communication between different components is vital for the engine’s performance, efficiency, and longevity.

SPECIFICATIONS

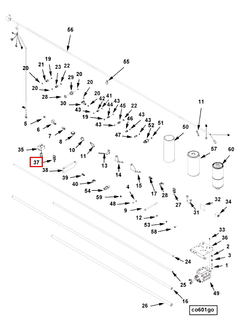

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.