This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

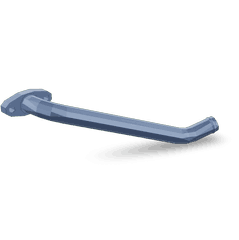

The Tur Oil Drain Tube, identified by part number 3279042, is a component designed for use in heavy-duty trucks. Its primary function is to facilitate the efficient drainage of oil from the engine during maintenance procedures. Cummins Inc., a well-established manufacturer in the automotive industry, produces this component. Known for its robust engineering and high-quality products, Cummins has a strong reputation in the heavy-duty truck sector 1.

Basic Concepts and Functionality

The Tur Oil Drain Tube operates on the fundamental principle of gravity-assisted oil drainage. When the tube is installed and the oil cap is removed, oil flows through the tube and out of the engine. This process is designed to be straightforward, allowing for quick and complete oil removal. The tube is engineered to fit securely within the truck’s lubrication system, ensuring that oil is directed away from the engine compartment during drainage 2.

Role in Truck Operation

In the operation of a truck, the Tur Oil Drain Tube plays a significant role by ensuring that oil changes are performed efficiently. This contributes to maintaining optimal engine performance and longevity. By allowing for quick and complete oil drainage, the tube helps in reducing downtime during maintenance, thus supporting the overall efficiency of truck operations. Additionally, it aids in preventing oil contamination and buildup, which can lead to engine wear and reduced performance over time 3.

Key Features

The Tur Oil Drain Tube is characterized by several design elements that enhance its functionality and durability. These include a robust construction that withstands the high temperatures and pressures within the engine compartment. The tube is also designed with a secure fitting mechanism to ensure it remains in place during operation and maintenance. Additionally, its material is chosen for its resistance to corrosion and wear, ensuring long-term reliability.

Benefits

The advantages provided by the Tur Oil Drain Tube are notable. It offers improved oil drainage efficiency, which translates to reduced maintenance time. This efficiency is crucial for fleet operations where minimizing downtime is key. Furthermore, the tube contributes to enhanced engine protection by ensuring that old oil is completely removed during maintenance, reducing the risk of contamination and engine damage.

Installation Process

Installing the Tur Oil Drain Tube requires following a series of steps to ensure proper fitting and function. Begin by ensuring the engine is cool and the oil has been allowed to settle. Remove the existing drain plug or tube, if present. Insert the Tur Oil Drain Tube into the designated port, ensuring a secure fit. It is important to follow the manufacturer’s guidelines to avoid common pitfalls such as improper fitting or leaks.

Troubleshooting Common Issues

Frequent problems associated with the Tur Oil Drain Tube may include leaks or difficulty in fitting. To address these issues, first, ensure that the tube is correctly installed and securely fitted. If leaks occur, check for any damage to the tube or the fitting port and replace if necessary. Regular inspection and maintenance can help prevent these issues.

Maintenance Tips

To ensure the longevity and optimal performance of the Tur Oil Drain Tube, regular maintenance practices are recommended. This includes inspecting the tube for signs of wear or damage before each use and ensuring it is securely fitted during installation. Additionally, keeping the area around the tube clean and free from debris can help prevent contamination and ensure smooth operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive industry, particularly in the heavy-duty truck sector. The company is known for its innovation, quality, and commitment to customer satisfaction, making it a preferred choice for professionals in the field.

Compatibility

The Tur Oil Drain Tube is compatible with a range of Cummins engines, including but not limited to:

- 6B5.9 Series: This part is integral to the 6B5.9 engine series, where it ensures that oil is properly drained from the turbocharger, preventing oil accumulation that could lead to performance issues or damage.

- Other Cummins Engines: The 3279042 Tur Oil Drain Tube is also suitable for various other Cummins engine models, providing a standardized solution for turbocharger oil drainage across multiple engine types.

Importance in Engine Maintenance

The Tur Oil Drain Tube plays a vital role in maintaining the health of the turbocharger by preventing oil from stagnating within the turbocharger housing. This is crucial for several reasons:

- Prevents Oil Contamination: By ensuring that oil is drained effectively, the part helps prevent oil contamination of the turbocharger, which can degrade performance and lead to mechanical failures.

- Enhances Efficiency: Proper oil drainage contributes to the overall efficiency of the engine by maintaining the correct oil levels and preventing oil-related issues that could affect the turbocharger’s operation.

- Prolongs Component Lifespan: By keeping the turbocharger oil clean and at the appropriate levels, the Tur Oil Drain Tube helps extend the lifespan of the turbocharger and other related components, reducing maintenance costs and downtime.

Installation and Usage

When installing the Tur Oil Drain Tube, it is essential to follow the manufacturer’s guidelines to ensure proper fit and function. This includes verifying the correct orientation and securing the tube to prevent leaks or disconnections during operation. Regular inspection and maintenance of the tube are also recommended to ensure it remains in good condition and continues to perform its intended function effectively.

Understanding the Role in Turbocharger Plumbing

The Tur Oil Drain Tube is an essential component in the turbocharger plumbing system, facilitating the efficient management of oil within the turbocharger assembly. This tube is specifically designed to allow the drainage of excess oil from the turbocharger, ensuring that the lubrication system operates within optimal parameters.

In the turbocharger plumbing, the Tur Oil Drain Tube connects to the turbocharger’s oil supply and return lines. It plays a significant role in maintaining the correct oil level within the turbocharger. Excess oil, if not properly drained, can lead to oil starvation or over-lubrication, both of which can adversely affect turbocharger performance and longevity.

The tube is integrated into the oil return circuit, where it channels the surplus oil back to the engine’s oil sump. This process ensures that the oil is continuously recirculated, maintaining a consistent oil level and pressure within the turbocharger. The efficient drainage provided by the Tur Oil Drain Tube helps prevent oil buildup, which can cause foaming and reduce the oil’s lubricating properties.

Additionally, the Tur Oil Drain Tube works in conjunction with other components such as the oil feed line, oil return line, and the turbocharger’s internal oil passages. These components collectively ensure that the turbocharger receives the necessary lubrication while excess oil is promptly removed. The tube’s placement and design are engineered to handle the high temperatures and pressures associated with turbocharger operation, ensuring reliable performance under various operating conditions.

Conclusion

The Tur Oil Drain Tube (Part #3279042) by Cummins is a critical component in the maintenance and operation of heavy-duty trucks. Its efficient oil drainage capability ensures optimal engine performance, reduces maintenance downtime, and prolongs the lifespan of engine components. Proper installation, regular maintenance, and understanding its role in turbocharger plumbing are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.