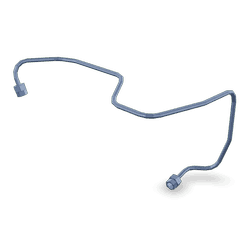

3283382

Injector Fuel Supply Tube

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Injector Fuel Supply Tube 3283382 is a component manufactured by Cummins, a well-established name in the commercial truck engine industry. This part is integral to the fuel system of diesel engines, ensuring efficient fuel delivery to the injectors. Cummins is renowned for its commitment to quality and innovation, making the Injector Fuel Supply Tube a significant component in maintaining the performance and reliability of commercial truck engines.

Basic Concepts of Injector Fuel Supply Tubes

An Injector Fuel Supply Tube is a conduit within the fuel system that facilitates the transfer of fuel from the fuel rail to the injectors. Its function is to provide a consistent and pressurized fuel supply, which is essential for the precise operation of fuel injectors. This, in turn, contributes to the overall efficiency and performance of a diesel engine by ensuring that fuel is delivered at the correct pressure and timing 1.

Role of the Injector Fuel Supply Tube in Truck Operation

The Injector Fuel Supply Tube plays a specific role in the fuel delivery system of a truck. It connects the fuel rail to the injectors, allowing for the distribution of fuel under pressure. This tube works in conjunction with other components such as the fuel injectors and fuel rail to maintain a steady fuel supply, which is vital for the combustion process in diesel engines. The efficient operation of this tube ensures that the injectors receive the necessary fuel pressure to atomize the fuel properly, leading to better combustion and engine performance 2.

Key Features of the Injector Fuel Supply Tube

The Injector Fuel Supply Tube is designed with several features that enhance its performance and durability. Constructed from high-quality materials, it is built to withstand the high pressures and temperatures within the fuel system. Its design includes precise engineering to ensure a secure fit and reliable seal, preventing fuel leaks. Additionally, the tube may feature unique characteristics such as reinforced sections or specialized coatings to further improve its resilience and performance.

Benefits of Using the Injector Fuel Supply Tube

Utilizing the Injector Fuel Supply Tube offers several advantages. It provides improved fuel delivery efficiency, ensuring that the injectors receive a consistent and pressurized fuel supply. This leads to enhanced engine performance, with better fuel atomization and combustion. The tube’s durable construction and reliable operation contribute to the overall reliability of the fuel system, reducing the likelihood of fuel leaks and system failures.

Installation and Integration

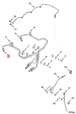

Proper installation of the Injector Fuel Supply Tube is crucial for its effective operation within the truck’s fuel system. It should be securely connected to both the fuel rail and the injectors, ensuring a tight seal to prevent fuel leaks. Specific considerations during installation may include verifying the correct orientation of the tube and ensuring that all connections are tightened to the manufacturer’s specifications. Following these guidelines will help integrate the tube seamlessly into the fuel system.

Troubleshooting Common Issues

Common problems associated with Injector Fuel Supply Tubes can include fuel leaks, reduced fuel pressure, or blockages. Potential causes may range from improper installation to wear and tear over time. Troubleshooting steps should begin with a visual inspection for any signs of damage or leaks. If a leak is detected, the connections should be re-tightened or the tube replaced if necessary. Reduced fuel pressure may indicate a blockage, requiring a thorough cleaning or replacement of the tube.

Maintenance Recommendations

To ensure optimal performance and longevity of the Injector Fuel Supply Tube, regular maintenance is recommended. This includes periodic inspection for signs of wear, corrosion, or leaks. Cleaning the tube and its connections can help prevent blockages and ensure a consistent fuel supply. Replacement guidelines should be followed if the tube shows significant wear or if fuel leaks persist despite maintenance efforts. Adhering to these maintenance practices will help maintain the efficiency and reliability of the fuel system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on technological advancement make it a trusted partner for commercial truck manufacturers and operators worldwide.

Cummins Injector Fuel Supply Tube (Part 3283382) Compatibility

The Cummins Injector Fuel Supply Tube, part number 3283382, is a critical component in the fuel delivery system of various Cummins engines. This part ensures that fuel is efficiently and accurately delivered to the injectors, which is essential for maintaining optimal engine performance and fuel efficiency.

Engine Compatibility

-

4B3.9 Series

- The Injector Fuel Supply Tube (3283382) is specifically designed to fit within the 4B3.9 engine series. This series is known for its robust design and reliability in heavy-duty applications. The part’s precision engineering ensures that it integrates seamlessly with the engine’s fuel system, providing a secure and leak-free connection.

-

Group Compatibility

- The part 3283382 is also compatible with other Cummins engine groups that utilize similar injector systems. This includes engines that share common design elements and specifications with the 4B3.9 series. Ensuring that the injector fuel supply tube is correctly installed is crucial for the overall efficiency and longevity of the engine.

Installation Considerations

-

Precision Fitment

- The injector fuel supply tube must be precisely fitted to avoid any fuel leaks or inefficiencies. This part is manufactured to exact specifications, ensuring a perfect match with the engine’s injector system.

-

Durability

- Constructed from high-quality materials, the injector fuel supply tube is designed to withstand the high pressures and temperatures encountered in diesel engines. This durability is essential for maintaining the integrity of the fuel system over the engine’s operational life.

-

Maintenance

- Regular inspection and maintenance of the injector fuel supply tube are recommended to ensure it remains in optimal condition. Any signs of wear or damage should be addressed promptly to prevent potential engine performance issues.

Role of Part 3283382 Injector Fuel Supply Tube in Engine Systems

The Injector Fuel Supply Tube, designated as part 3283382, is an integral component within the fuel delivery system of an engine. Its primary function is to facilitate the precise and efficient transfer of fuel from the fuel rail to the individual fuel injectors.

In the context of fuel plumbing, the Injector Fuel Supply Tube ensures a consistent and uninterrupted flow of fuel. This is essential for maintaining the correct fuel pressure and delivery rate, which directly impacts engine performance and efficiency. The tube connects to the fuel rail, which distributes fuel to all injectors, and extends to each injector, providing a dedicated pathway for fuel to travel.

The interaction between the Injector Fuel Supply Tube and the fuel injectors is particularly noteworthy. Each injector relies on a steady supply of fuel to atomize and deliver it into the combustion chamber at the precise moment. The tube’s design minimizes fuel leakage and ensures that fuel is delivered under the correct pressure, which is vital for the injectors to function optimally.

Furthermore, the Injector Fuel Supply Tube plays a role in the overall integrity of the fuel system. It must withstand the high pressures and temperatures within the fuel rail while remaining flexible enough to accommodate the movement and vibrations inherent in engine operation. This durability ensures that the fuel supply remains consistent, even under varying engine loads and speeds.

In summary, the Injector Fuel Supply Tube (part 3283382) is a key element in the fuel delivery system, ensuring that fuel is efficiently and reliably supplied to the injectors, which in turn contributes to the engine’s performance and fuel economy.

Conclusion

The Injector Fuel Supply Tube 3283382 by Cummins is a vital component in the fuel delivery system of diesel engines. Its role in ensuring efficient and reliable fuel delivery to the injectors is critical for maintaining engine performance and fuel efficiency. Proper installation, regular maintenance, and understanding its compatibility with various Cummins engines are essential for maximizing the benefits of this part. Cummins’ commitment to quality and innovation is evident in the design and functionality of the Injector Fuel Supply Tube, making it a trusted component in the commercial truck industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.