This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

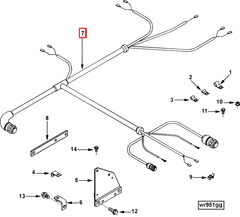

The 3284748 Wiring Harness is a product manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This Cummins part is significant in commercial trucks as it plays a role in the electrical system, ensuring the efficient operation of various components.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle. It consists of multiple wires bundled together, often protected by conduits or sheathing, to prevent damage and reduce electromagnetic interference. Within a vehicle’s electrical system, the wiring harness facilitates communication between different components, ensuring they operate in unison 1.

Purpose of the 3284748 Wiring Harness

This part is designed to support the electrical needs of commercial trucks. It integrates with various systems within the truck, such as the engine control unit (ECU), lighting systems, and other electronic components. By providing a structured pathway for electrical signals and power, it ensures that these systems function correctly and efficiently.

Key Features

The 3284748 Wiring Harness is characterized by several key features. Its design is tailored to meet the demanding requirements of commercial trucks, with robust construction to withstand harsh environments. The materials used in its production are chosen for their durability and resistance to wear and tear. Additionally, the harness may include unique attributes such as specialized connectors or shielding to enhance performance and reliability.

Benefits

The advantages of the 3284748 Wiring Harness include improved efficiency in the electrical system, enhanced reliability through its durable construction, and increased safety due to its robust design. These benefits contribute to the overall performance and longevity of the truck, making it a valuable component for fleet operators.

Installation Process

Proper installation of the 3284748 Wiring Harness involves several steps. It begins with ensuring the truck’s electrical system is powered down to prevent any risk of electrical shock. The harness should be routed according to the manufacturer’s guidelines to avoid interference with other components. Secure connections are crucial, and all terminals should be tightened to the specified torque. Testing the system post-installation is recommended to confirm proper functionality.

Troubleshooting Common Issues

Common problems with wiring harnesses can include loose connections, damaged wires, or faulty connectors. Troubleshooting these issues involves a systematic approach to identify the source of the problem. This may include visual inspections, testing for continuity, and using diagnostic tools to pinpoint electrical faults. Solutions can range from repairing or replacing damaged sections to re-securing loose connections.

Maintenance Tips

Regular maintenance of the 3284748 Wiring Harness is important for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, ensuring all connections are secure, and protecting the harness from physical damage or exposure to harsh chemicals. Keeping the harness clean and dry can also prevent corrosion and extend its lifespan.

Safety Considerations

When working with the 3284748 Wiring Harness, it is important to observe safety protocols. This includes ensuring the truck’s electrical system is off before beginning any work to avoid the risk of electrical shock. Using appropriate personal protective equipment (PPE) and following manufacturer guidelines for installation and maintenance are also crucial safety measures.

Cummins: A Brief Overview

Cummins is a renowned manufacturer with a long-standing reputation in the production of automotive components. Known for their commitment to quality and innovation, Cummins has a history of delivering reliable and high-performance parts for the automotive and heavy-duty truck industries. Their products are designed with a focus on durability, efficiency, and safety, making them a preferred choice for fleet operators and mechanics alike.

Cummins Wiring Harness 3284748 Compatibility

The Cummins Wiring Harness part number 3284748 is designed to integrate seamlessly with various engine models, ensuring reliable electrical connectivity and performance. This wiring harness is engineered to meet the specific needs of the engines it supports, providing a robust and efficient solution for managing electrical systems.

Engine Compatibility

- 6B5.9 Series

- The 3284748 wiring harness is compatible with the 6B5.9 engine series, ensuring that all electrical components are properly connected and functioning. This compatibility is crucial for maintaining the engine’s performance and reliability.

Integration and Functionality

-

Electrical System Integration

- The 3284748 wiring harness is designed to integrate with the engine’s electrical system, ensuring that all necessary components receive power and signals. This includes connections to the engine control module (ECM), sensors, and other critical components.

-

Durability and Reliability

- Constructed with high-quality materials, the 3284748 wiring harness is built to withstand the harsh conditions of engine operation. This durability ensures long-term reliability and reduces the risk of electrical failures.

-

Ease of Installation

- The harness is designed for easy installation, minimizing downtime and ensuring that the engine can return to operation quickly. This ease of installation is particularly important for maintaining productivity in commercial and industrial applications.

Performance Benefits

-

Enhanced Electrical Performance

- By providing a secure and efficient connection between electrical components, the 3284748 wiring harness helps to enhance the overall electrical performance of the engine. This can lead to improved efficiency and reduced energy consumption.

-

Reduced Downtime

- With its reliable design and ease of installation, the 3284748 wiring harness helps to reduce downtime, ensuring that the engine remains operational and productive. This is particularly important for businesses that rely on continuous engine operation.

-

Compatibility with Other Cummins Products

- The 3284748 wiring harness is designed to work seamlessly with other Cummins products, ensuring a cohesive and integrated system. This compatibility is essential for maintaining the overall performance and reliability of the engine and its associated systems.

Role of Part 3284748 Wiring Harness in Engine Systems

The Part 3284748 Wiring Harness is an integral component in the electrical system of engine setups, facilitating the seamless operation of various accessories and ensuring efficient power distribution.

Integration with Accessories

This wiring harness is designed to connect a wide array of accessories to the engine’s electrical system. These accessories may include but are not limited to:

- Alternators: The harness provides the necessary connections for the alternator to charge the battery and power the electrical system while the engine is running.

- Starters: It ensures that the starter motor receives the correct voltage to crank the engine.

- Sensors: Various sensors, such as the oxygen sensor, mass airflow sensor, and engine temperature sensor, rely on the wiring harness for data transmission to the engine control unit (ECU).

- Ignition Systems: Components like the ignition coil and spark plugs are powered and controlled through the harness, ensuring precise timing and efficient combustion.

- Fuel Injectors: The harness delivers signals from the ECU to the fuel injectors, regulating fuel delivery for optimal engine performance.

- Lighting Systems: Headlights, taillights, and indicator lights are connected via the harness, ensuring they function correctly.

- Entertainment Systems: In some vehicles, the harness may also integrate with entertainment systems, providing power and connectivity.

Wiring Coordination

The Part 3284748 Wiring Harness acts as the central nervous system for the engine’s electrical components. It:

- Routes Power: Efficiently routes electrical power from the battery to various components, ensuring each part receives the correct voltage.

- Manages Signals: Facilitates the transmission of signals between the ECU and various sensors and actuators, allowing for real-time adjustments and optimal performance.

- Protects Circuits: Incorporates fuses and relays to protect the electrical system from overloads and short circuits, enhancing the reliability and safety of the engine system.

- Reduces Clutter: Organizes wires into a single, manageable unit, reducing the risk of chafing, fraying, or accidental disconnections.

- Enhances Maintenance: Simplifies the process of diagnosing and repairing electrical issues by providing clear pathways and connections.

Conclusion

In summary, the Part 3284748 Wiring Harness plays a significant role in maintaining the electrical integrity and functionality of engine systems, ensuring that all connected accessories operate harmoniously and efficiently. Its robust design, ease of installation, and compatibility with various engine models make it a valuable component for commercial and industrial applications.

-

Huang, Matthew. Vehicle Crash Dynamics. CRC Press, 2002.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.