This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

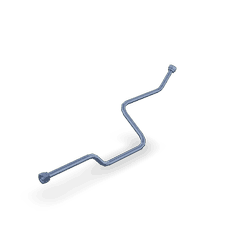

The Compressor Water Outlet Tube, identified by part number 3286390 and manufactured by Cummins, is a critical component in the cooling systems of heavy-duty trucks. This part is essential for maintaining efficient operation and longevity of the engine and compressor.

Basic Concepts and Functionality

The Compressor Water Outlet Tube operates on fundamental principles of fluid dynamics and thermal management. It facilitates the flow of coolant from the compressor to other parts of the cooling system, interacting with components such as the radiator and engine block to maintain consistent temperatures. This is vital for the efficient operation of the truck’s engine and compressor 1.

Purpose and Role in Truck Operation

This Cummins part serves a specific function within the truck’s operational framework. It contributes to maintaining optimal temperatures for both the compressor and the engine. By efficiently routing coolant, it helps prevent overheating, which can lead to reduced performance and potential damage to engine components 2.

Key Features

The Compressor Water Outlet Tube is characterized by several key features that enhance its performance and durability. These include its material composition, designed to withstand high temperatures and pressures, and its precise design elements that ensure a secure fit and efficient coolant flow. Additionally, the tube may incorporate unique characteristics such as reinforced sections to handle stress points and ensure longevity 3.

Benefits

The advantages of the Compressor Water Outlet Tube are manifold. It offers improved cooling efficiency, which is crucial for maintaining engine and compressor performance under various operating conditions. Its durable construction contributes to the overall reliability of the truck’s cooling system. Furthermore, by ensuring optimal temperatures, it potentially enhances engine performance and longevity.

Installation and Integration

Proper installation and integration of the Compressor Water Outlet Tube within a truck’s cooling system are paramount. It is important to ensure compatibility with other components and systems to maintain the integrity of the cooling process. Guidelines for installation should be followed to ensure that the tube is securely fitted and functions as intended within the system.

Troubleshooting and Maintenance

Common issues associated with the Compressor Water Outlet Tube may include leaks or blockages, which can impede the flow of coolant. Diagnostic procedures should be employed to identify such issues, and maintenance practices, such as regular inspections and cleaning, should be undertaken to ensure optimal performance and longevity of the tube.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, related technologies, and complete power systems. With a rich history and a strong reputation in the automotive and heavy-duty truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and global presence underscore its position as a leader in the industry.

Role of Part 3286390 Compressor Water Outlet Tube in Engine Systems

The Compressor Water Outlet Tube (part 3286390) is an essential component within the compressor coolant plumbing system. Its primary function is to facilitate the efficient transfer of coolant from the compressor to other parts of the engine system.

In the context of the compressor coolant plumbing, the Compressor Water Outlet Tube ensures that the coolant, after absorbing heat from the compressor, is directed to the appropriate areas where it can dissipate this heat. This process is vital for maintaining optimal operating temperatures and preventing overheating of the compressor and surrounding components.

The tube interfaces with various components such as the coolant reservoir, heat exchanger, and coolant return lines. By providing a dedicated pathway for the coolant, it helps in stabilizing the thermal environment around the compressor. This, in turn, enhances the overall efficiency and reliability of the engine system.

Additionally, the Compressor Water Outlet Tube works in conjunction with thermostats and coolant flow sensors to ensure that the coolant circulation is consistent and aligned with the engine’s thermal management requirements. This integration allows for precise control over the coolant flow, adapting to varying operational conditions and loads.

Conclusion

In summary, the Compressor Water Outlet Tube plays a significant role in the thermal management of engine systems by ensuring effective coolant distribution and maintaining the integrity and performance of the compressor and associated components.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.