This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

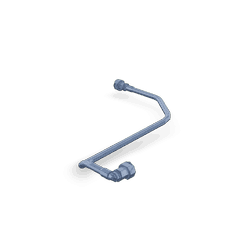

The Compressor Water Inlet Tube (Part #3287210) manufactured by Cummins is a component designed to facilitate the efficient operation of heavy-duty trucks. This part is integral to the truck’s cooling system, ensuring that the engine operates within optimal temperature ranges. Its role is significant in maintaining the overall performance and longevity of the engine 1.

Basic Concepts and Functionality

The Compressor Water Inlet Tube operates on the fundamental principle of fluid dynamics within the truck’s cooling system. It serves as a conduit for water to enter the compressor, where it aids in cooling the compressed air before it enters the engine. This process is vital for dissipating heat generated during compression, which if not managed, could lead to decreased engine efficiency and potential damage 2. The tube interacts with other components such as the radiator, thermostat, and engine block to maintain a balanced cooling system.

Purpose and Role in Truck Operation

Within the truck’s engine system, the Compressor Water Inlet Tube plays a specific role in ensuring that the engine maintains an optimal operating temperature. By allowing water to flow into the compressor, it helps in cooling the compressed air, which in turn contributes to more efficient combustion and reduced thermal stress on engine components. This function is particularly important in heavy-duty trucks, where engines are subjected to high loads and operating conditions 3.

Key Features

The design and construction of the Compressor Water Inlet Tube are tailored to meet the demanding requirements of heavy-duty truck applications. It is made from durable materials that can withstand high pressures and temperatures. The tube’s construction includes precise fittings and connections to ensure a secure and leak-free installation. Additionally, its design may incorporate features that enhance flow efficiency and reduce the risk of blockages, contributing to its overall performance and reliability.

Benefits

The advantages provided by the Compressor Water Inlet Tube include improved engine efficiency, enhanced longevity, and increased reliability. By effectively managing the temperature of the compressed air, it contributes to more consistent engine performance under varying load conditions. This not only improves the overall efficiency of the truck but also extends the lifespan of the engine by reducing thermal stress. Furthermore, the reliability of the cooling system is increased, leading to fewer breakdowns and maintenance requirements.

Installation and Compatibility

Proper installation of the Compressor Water Inlet Tube is crucial for its effective operation. It is designed to be compatible with various Cummins engine models, ensuring a seamless integration into the truck’s cooling system. Specific guidelines for installation should be followed to ensure that all connections are secure and that the tube is properly aligned within the system. This may include checking for compatibility with existing components and ensuring that all seals and gaskets are in good condition.

Maintenance and Troubleshooting

Maintaining the Compressor Water Inlet Tube involves regular inspection routines to ensure its continued performance. This includes checking for signs of wear, corrosion, or leaks, and ensuring that all connections remain tight. Common issues to watch for may include blockages within the tube or damage to the fittings. Troubleshooting steps may involve cleaning the tube, replacing damaged components, or adjusting the system to ensure optimal flow. Regular maintenance can help prevent more serious issues and ensure the longevity of the component.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the automotive industry, particularly in the heavy-duty truck sector. The company is committed to manufacturing high-quality components that meet the rigorous demands of heavy-duty applications, ensuring reliability and performance in every product they offer.

Compatibility of Compressor Water Inlet Tube (Part 3287210) with Cummins Engines

The Compressor Water Inlet Tube, part number 3287210, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This part is integral to the engine’s cooling system, ensuring efficient water flow to the compressor. Here is a detailed look at its compatibility across various Cummins engines:

ISB/ISD4.5 CM2150 B119

The ISB/ISD4.5 CM2150 B119 engine is a robust and reliable power unit, often utilized in heavy-duty applications. The Compressor Water Inlet Tube for this engine is specifically engineered to match the unique design and requirements of the CM2150 B119 model, ensuring optimal performance and longevity.

ISBE CM800

The ISBE CM800 engine is another high-performance model in Cummins’ lineup. The Compressor Water Inlet Tube for this engine is crafted to integrate perfectly with the ISBE CM800, providing essential cooling capabilities that help maintain engine efficiency and reliability.

ISBE4 CM850

Similar to the ISBE CM800, the ISBE4 CM850 engine benefits from the precise fit of the Compressor Water Inlet Tube, part number 3287210. This part is designed to handle the specific demands of the CM850 model, ensuring that the engine operates at peak performance levels.

Grouping of Compatible Engines

While the Compressor Water Inlet Tube is tailored for specific engine models, it is worth noting that the ISBE CM800 and ISBE4 CM850 share similarities in their design and operational requirements. This commonality allows for a more straightforward integration of the part across these models, simplifying maintenance and repair processes.

By ensuring that the Compressor Water Inlet Tube is correctly matched with the respective engine models, users can maintain the integrity of their cooling systems and extend the operational life of their engines.

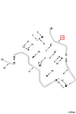

Role of Part 3287210 Compressor Water Inlet Tube in Engine Systems

The Part 3287210 Compressor Water Inlet Tube is an essential element in the compressor coolant arrangement and compressor coolant plumbing of engine systems. This component facilitates the precise and efficient introduction of coolant into the compressor system, ensuring optimal thermal management.

In the compressor coolant arrangement, the inlet tube is responsible for directing coolant flow to the compressor’s critical areas. This helps in maintaining the compressor’s temperature within specified limits, thereby enhancing its efficiency and longevity. The tube’s design allows for consistent coolant distribution, which is vital for uniform cooling across the compressor components.

Within the compressor coolant plumbing, the inlet tube acts as a vital conduit that connects the coolant supply to the compressor. It ensures that the coolant reaches the compressor without any interruptions or leaks, which could otherwise lead to inefficient cooling and potential damage to the compressor. The tube’s integration into the plumbing system is designed to withstand the pressures and temperatures associated with engine operations, providing reliable performance over time.

Overall, the Part 3287210 Compressor Water Inlet Tube plays a significant role in ensuring that the compressor operates within its thermal limits, contributing to the overall efficiency and reliability of the engine system.

Conclusion

The Compressor Water Inlet Tube (Part #3287210) by Cummins is a critical component in the cooling system of heavy-duty trucks, ensuring optimal engine performance and longevity. Its design and functionality are tailored to meet the demanding requirements of heavy-duty applications, providing benefits such as improved engine efficiency, enhanced longevity, and increased reliability. Proper installation, maintenance, and compatibility with Cummins engines are essential for its effective operation. By understanding the role and benefits of this part, users can ensure the continued efficiency and reliability of their truck’s engine system.

-

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Lejda, Kazimierz, and Pawel Wos. Internal Combustion Engines. InTech, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.