3287408

Compressor Water Outlet Tube

Cummins®

AVAILABLE

5 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Compressor Water Outlet Tube, identified by part number 3287408, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This tube is integral to the cooling systems of heavy-duty trucks, ensuring efficient operation and longevity of the engine 1.

Function and Operation

The Compressor Water Outlet Tube operates by directing the flow of coolant from the compressor to other parts of the engine cooling system. It ensures that the coolant is evenly distributed, which helps in maintaining optimal engine temperature. The tube is designed to handle the pressure and temperature variations within the cooling system, facilitating smooth and consistent coolant flow 2.

Purpose of the Compressor Water Outlet Tube

In the operation of a truck, the Compressor Water Outlet Tube plays a specific role within the cooling system. It ensures that the coolant, after absorbing heat from the compressor, is effectively routed to other areas of the engine that require cooling. This process is vital for maintaining engine performance and preventing overheating, which can lead to engine damage 3.

Key Features

The Compressor Water Outlet Tube is constructed from durable materials that can withstand the high pressures and temperatures encountered in heavy-duty truck engines. Its design includes precise fittings and connections that ensure a secure and leak-free integration into the cooling system. Additionally, the tube may feature reinforced sections to enhance its durability and resistance to wear and corrosion 4.

Benefits

The use of the Compressor Water Outlet Tube offers several advantages. It contributes to improved engine cooling efficiency by ensuring that coolant is effectively distributed throughout the engine. The durable construction of the tube enhances its longevity, reducing the need for frequent replacements. Furthermore, its reliable performance contributes to the overall reliability of the truck’s cooling system 5.

Installation and Integration

Proper installation of the Compressor Water Outlet Tube is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines, ensuring that all connections are secure and that the tube is correctly aligned within the cooling system. Preparations may include cleaning the installation area and inspecting the tube for any defects before installation 6.

Maintenance and Troubleshooting

Regular maintenance of the Compressor Water Outlet Tube is recommended to ensure its optimal performance. This includes checking for leaks, inspecting the tube for signs of wear or corrosion, and ensuring that all connections remain secure. Common issues may include leaks at connection points or blockages within the tube, which can be addressed through proper troubleshooting procedures 7.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its commitment to quality and innovation in the automotive industry. With a history of producing reliable and high-performance components, Cummins has established a strong reputation among commercial vehicle operators and manufacturers alike. The company’s dedication to excellence is reflected in its wide range of products, including the Compressor Water Outlet Tube 8.

Compressor Water Outlet Tube for Cummins Engines

The Compressor Water Outlet Tube, part number 3287408, is a critical component in the cooling system of several Cummins engine models. This part is designed to efficiently manage the flow of coolant from the compressor section of the engine, ensuring optimal operating temperatures and preventing overheating.

B6.7 CM2670 B153B

In the B6.7 CM2670 B153B engine, the Compressor Water Outlet Tube is integral to the cooling system’s performance. It ensures that coolant is effectively circulated from the compressor, maintaining the engine’s efficiency and longevity.

ISB/ISD4.5 CM2150 B119

For the ISB/ISD4.5 CM2150 B119 engine, the Compressor Water Outlet Tube plays a vital role in the cooling system. This part helps maintain the correct coolant flow, which is essential for the engine’s performance and durability.

ISB/ISD6.7 CM2150 SN

In the ISB/ISD6.7 CM2150 SN engine, the Compressor Water Outlet Tube is designed to handle the specific cooling requirements of this engine model. It ensures that the coolant is efficiently managed, contributing to the engine’s overall reliability and efficiency.

ISBE CM2150

The ISBE CM2150 engine also utilizes the Compressor Water Outlet Tube to maintain proper coolant circulation. This part is essential for the engine’s cooling system, ensuring that the compressor section operates within the optimal temperature range.

ISBE CM800

In the ISBE CM800 engine, the Compressor Water Outlet Tube is a key component in the cooling system. It ensures that the coolant is effectively managed, contributing to the engine’s performance and longevity.

ISBE4 CM850

For the ISBE4 CM850 engine, the Compressor Water Outlet Tube is designed to handle the specific cooling needs of this engine model. It ensures that the coolant is efficiently circulated, maintaining the engine’s optimal operating conditions.

QSB7 CM2880 B117

In the QSB7 CM2880 B117 engine, the Compressor Water Outlet Tube is crucial for the cooling system’s efficiency. This part ensures that the coolant is effectively managed, contributing to the engine’s performance and durability.

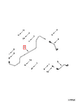

Role of Part 3287408 Compressor Water Outlet Tube in Engine Systems

The Compressor Water Outlet Tube is integral to the efficient operation of the Compressor Coolant Arrangement and Compressor Coolant Plumbing. This component facilitates the controlled flow of coolant from the compressor to other parts of the engine system, ensuring optimal thermal management.

In the Compressor Coolant Arrangement, the outlet tube connects to the compressor’s coolant passages, allowing the coolant to exit the compressor after absorbing heat. This heat transfer is vital for maintaining the compressor’s operational temperature within safe limits, thereby enhancing its longevity and performance.

Within the Compressor Coolant Plumbing, the tube acts as a conduit that directs the coolant to the next stage of the cooling circuit. This may include heat exchangers, radiators, or other cooling components designed to dissipate the absorbed heat away from the engine system. The precise routing provided by the outlet tube ensures that coolant flow is consistent and unimpeded, supporting the overall efficiency of the cooling process.

Additionally, the tube’s design allows for easy integration with various fittings and connectors, simplifying the installation and maintenance processes. Its robust construction ensures durability under high-pressure conditions, contributing to the reliability of the coolant system 9.

Conclusion

The Compressor Water Outlet Tube, part number 3287408, is a vital component in the cooling systems of Cummins engines. Its role in ensuring efficient coolant distribution and maintaining optimal engine temperatures is critical for the performance and longevity of heavy-duty trucks. Proper installation, regular maintenance, and understanding its function within the engine system are essential for maximizing the benefits of this Cummins part.

-

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩ -

Jazar, R. N. (2017). Vehicle Dynamics: Theory and Application. Springer.

↩ -

Goodnight, N., & Van Gelder, K. (2018). Automotive Braking Systems. Jones & Bartlett Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5660005.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5660005.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5660005.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5660005.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5660005.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5660005.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.