This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

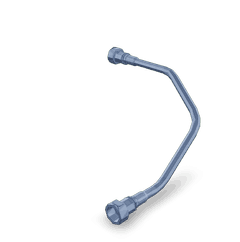

The 3287410 Compressor Water Inlet Tube, a component manufactured by Cummins, is integral to the operation of heavy-duty trucks, contributing to the efficiency and performance of the engine cooling system.

Basic Concepts of Compressor Water Inlet Tubes

A Compressor Water Inlet Tube facilitates the flow of coolant into the compressor. Within the engine cooling system, it ensures that the compressor receives a steady supply of coolant, which helps in maintaining optimal operating temperatures. This tube interacts with various components of the cooling system, including the radiator, thermostat, and water pump, to ensure efficient heat dissipation 1.

Role of the 3287410 Compressor Water Inlet Tube in Truck Operation

The 3287410 Compressor Water Inlet Tube is specifically designed to enhance the operation of heavy-duty trucks. It contributes to engine efficiency by ensuring that the compressor remains cool under high-stress conditions. This, in turn, helps in maintaining the overall performance of the truck, allowing it to operate smoothly even under demanding circumstances 2.

Key Features of the 3287410 Compressor Water Inlet Tube

The 3287410 Compressor Water Inlet Tube is characterized by its robust design and high-quality construction. It is made from durable materials that can withstand the rigors of heavy-duty applications. The tube is engineered to provide a reliable connection within the cooling system, ensuring that coolant flows efficiently to the compressor. Its design also includes features that enhance its durability and resistance to wear and tear 3.

Benefits of Using the 3287410 Compressor Water Inlet Tube

Using the 3287410 Compressor Water Inlet Tube offers several advantages. It provides improved cooling efficiency, which is vital for the longevity and performance of the engine. The tube’s durable construction ensures that it can withstand the demands of heavy-duty use, offering reliability in various operating conditions. Additionally, its precise engineering contributes to the overall efficiency of the cooling system, helping to maintain optimal engine temperatures.

Installation and Integration

Proper installation of the 3287410 Compressor Water Inlet Tube is crucial for its effective operation. It should be integrated into the truck’s engine system with care, ensuring that all connections are secure and that the tube is properly aligned within the cooling system. Following manufacturer guidelines during installation will help in achieving the best performance from this component.

Maintenance and Care

Routine maintenance of the 3287410 Compressor Water Inlet Tube is important to ensure its optimal performance and longevity. Regular inspections should be conducted to check for any signs of wear or damage. Cleaning the tube and ensuring that all connections are tight will help in maintaining its efficiency. Additionally, monitoring the overall condition of the cooling system will contribute to the tube’s effective operation.

Troubleshooting Common Issues

Common problems associated with Compressor Water Inlet Tubes may include leaks, blockages, or damage to the tube itself. Troubleshooting these issues involves inspecting the tube for any visible signs of damage, checking for proper alignment within the cooling system, and ensuring that all connections are secure. Addressing these issues promptly will help in maintaining the efficiency of the cooling system and the overall performance of the truck.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the automotive and heavy-duty truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s product range includes a variety of components and systems designed to enhance the performance and efficiency of vehicles and equipment.

Compatibility of Compressor Water Inlet Tube (Part 3287410) with Cummins Engines

The Compressor Water Inlet Tube (Part 3287410) manufactured by Cummins is designed to fit a variety of Cummins engines, ensuring efficient water flow to the engine’s compressor. This part is crucial for maintaining optimal engine performance by regulating the temperature of the compressed air entering the engine.

B6.7 and ISB/ISD6.7 Engines

The Compressor Water Inlet Tube is compatible with the B6.7 CM2350 and ISB/ISD6.7 CM2150 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The part ensures that the water inlet system functions correctly, preventing overheating and ensuring efficient cooling of the compressed air.

ISBE Engines

The ISBE CM2150 and ISBE CM800 engines also utilize the Compressor Water Inlet Tube. These engines are typically found in on-highway and vocational applications, where consistent performance and durability are paramount. The part’s design allows for seamless integration with the engine’s cooling system, ensuring that the compressor operates within safe temperature limits.

ISBE4 Engines

The ISBE4 CM850 engine is another model that benefits from the Compressor Water Inlet Tube. This engine is designed for high-performance applications, and the part plays a critical role in maintaining the engine’s efficiency and longevity by managing the temperature of the compressed air.

QSB7 Engine

Lastly, the QSB7 CM2880 B117 engine is compatible with the Compressor Water Inlet Tube. This engine is often used in a variety of applications, including agriculture and construction, where it needs to perform reliably under demanding conditions. The part ensures that the engine’s cooling system operates effectively, contributing to the overall performance and durability of the engine.

Role of Part 3287410 Compressor Water Inlet Tube in Engine Systems

The Part 3287410 Compressor Water Inlet Tube is integral to the efficient operation of the Compressor Coolant Arrangement and Compressor Coolant Plumbing. This component facilitates the precise delivery of coolant into the compressor system, ensuring optimal thermal management.

In the Compressor Coolant Arrangement, the inlet tube works in conjunction with various sensors and control valves to maintain the desired coolant flow rate and temperature. This arrangement is designed to protect the compressor from overheating, which can lead to reduced efficiency and potential damage. The tube’s role is to provide a consistent and reliable pathway for the coolant, allowing for effective heat dissipation from the compressor components.

Within the Compressor Coolant Plumbing, the inlet tube is a key element that connects to the main coolant supply line. It ensures that the coolant is distributed evenly across the compressor, preventing hot spots and ensuring uniform cooling. This is particularly important in high-performance engines where the compressor operates under extreme conditions.

The integration of the Part 3287410 Compressor Water Inlet Tube into these systems enhances the overall reliability and performance of the engine. By maintaining the compressor at an optimal operating temperature, the tube contributes to the longevity and efficiency of the engine components.

Conclusion

The 3287410 Compressor Water Inlet Tube is a vital component in the engine cooling system of heavy-duty trucks. Its robust design, durable construction, and precise engineering contribute to the efficient operation of the compressor and the overall performance of the engine. Proper installation, routine maintenance, and prompt troubleshooting of common issues are essential to ensure the optimal performance and longevity of this Cummins part.

-

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩ -

Watson, Ben. Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning, 2011.

↩ -

Majewski, Addy, and Hannu Jaskelainen. Diesel Emissions and Their Control: Second Edition. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.