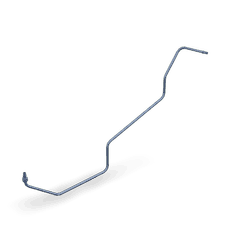

3287414

Compressor Water Outlet Tube

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Compressor Water Outlet Tube, identified by Part #3287414, is a component manufactured by Cummins, a leading name in the automotive and heavy-duty truck industry. This tube is integral to the cooling system of heavy-duty trucks, ensuring efficient operation of the engine by managing the flow of coolant 1.

Function and Operation

The Compressor Water Outlet Tube operates by directing the flow of coolant from the compressor to other parts of the engine system. It is strategically positioned to facilitate the even distribution of coolant, which is vital for maintaining optimal engine temperature. The tube connects to the compressor and extends to the engine’s cooling system, allowing coolant to circulate effectively 2.

Purpose of the Compressor Water Outlet Tube

The primary role of the Compressor Water Outlet Tube is to contribute to the engine’s efficiency and performance by ensuring that the compressor and other engine components remain at an optimal operating temperature. By facilitating the smooth flow of coolant, it helps prevent overheating, which can lead to engine damage and reduced performance 3.

Key Features

The Compressor Water Outlet Tube is characterized by its durable material composition, typically made from high-quality metal or composite materials that can withstand the high pressures and temperatures of the engine environment. Its design includes precise fittings and connections to ensure a secure and leak-free installation. Additionally, the tube may feature reinforced sections to enhance its durability and resistance to wear.

Benefits

The advantages of the Compressor Water Outlet Tube include improved engine cooling, which is crucial for maintaining engine efficiency and longevity. Its robust construction contributes to increased durability, reducing the likelihood of leaks or failures. Furthermore, by ensuring efficient coolant flow, it may contribute to better fuel efficiency, as a well-cooled engine operates more effectively.

Installation and Compatibility

Proper installation of the Compressor Water Outlet Tube is critical for its effective operation. It should be installed according to the manufacturer’s guidelines, ensuring that all connections are secure and that the tube is correctly aligned with the compressor and the engine’s cooling system. Compatibility with various truck models should be verified to ensure optimal performance and integration within the engine system.

Maintenance and Troubleshooting

Routine maintenance of the Compressor Water Outlet Tube involves inspecting it for signs of wear, corrosion, or leaks. Regular checks can help identify potential issues before they lead to more significant problems. Common issues may include blockages or leaks, which can be addressed by cleaning the tube or replacing damaged sections. It is also important to ensure that the tube is free from obstructions and that all connections are tight.

Safety Considerations

When working with the Compressor Water Outlet Tube, it is important to observe safety protocols. This includes ensuring that the engine is cool before beginning any maintenance or installation work. Protective equipment should be worn to prevent injuries from sharp edges or hot surfaces. Additionally, following the manufacturer’s guidelines for installation and maintenance will help ensure safe and effective operation of the component.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. Their product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial and industrial applications.

Compatibility of Compressor Water Outlet Tube (Part 3287414) with Cummins Engines

The Compressor Water Outlet Tube, part number 3287414, manufactured by Cummins, is designed to fit several of their engine models. This part is integral to the engine’s cooling system, ensuring efficient water flow from the compressor to the radiator or cooling system.

ISB/ISD6.7 CM2150 SN and ISBE CM2150

Both the ISB/ISD6.7 CM2150 SN and ISBE CM2150 engines are part of Cummins’ mid-range diesel engine lineup. The Compressor Water Outlet Tube for these engines is engineered to handle the specific cooling requirements of these models, ensuring optimal performance and longevity.

ISBE CM800 and ISBE4 CM850

The ISBE CM800 and ISBE4 CM850 engines, which are part of Cummins’ larger diesel engine series, also utilize the 3287414 Compressor Water Outlet Tube. This part is critical in maintaining the cooling efficiency of these engines, which are often used in heavy-duty applications.

QSB6.7 CM850 (CM2850) and QSB7 CM2880 B117

The QSB6.7 CM850 (CM2850) and QSB7 CM2880 B117 engines, which belong to Cummins’ high-performance diesel engine range, also incorporate the 3287414 Compressor Water Outlet Tube. This part is essential for these engines, which are typically used in demanding industrial and agricultural applications.

Conclusion

The Compressor Water Outlet Tube (Part 3287414) is a versatile component that fits into various Cummins engine models, including the ISB/ISD6.7 CM2150 SN, ISBE CM2150, ISBE CM800, ISBE4 CM850, QSB6.7 CM850 (CM2850), and QSB7 CM2880 B117. This part is crucial for maintaining the cooling efficiency of these engines, ensuring they operate at peak performance across different applications.

Role of Part 3287414 Compressor Water Outlet Tube in Engine Systems

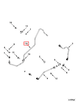

The part 3287414 Compressor Water Outlet Tube is an integral component in the compressor coolant arrangement and compressor coolant plumbing of engine systems. Its primary function is to facilitate the efficient transfer of coolant from the compressor to other parts of the engine system that require cooling.

In the compressor coolant arrangement, the Compressor Water Outlet Tube ensures that the coolant, after absorbing heat from the compressor, is directed away to prevent overheating. This tube is strategically positioned to connect the compressor to the coolant return path, allowing for a continuous flow of coolant that maintains optimal operating temperatures.

Within the compressor coolant plumbing, the Compressor Water Outlet Tube plays a significant role in the overall coolant circulation system. It interfaces with various hoses, fittings, and radiator components to ensure that the coolant is evenly distributed. This helps in dissipating heat effectively, thereby enhancing the longevity and performance of the compressor and associated engine components.

The efficient design of the Compressor Water Outlet Tube also contributes to minimizing coolant leakage and ensuring a secure connection within the plumbing system. This reliability is essential for maintaining consistent coolant levels and pressure, which are vital for the proper functioning of the engine’s cooling system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.