This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

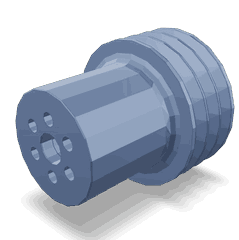

The Cummins 3326140 Crankshaft Pulley is a component designed for use in heavy-duty truck engines. Its purpose is to facilitate the operation of various engine accessories by transferring rotational force from the crankshaft. This part is significant in ensuring the efficient and reliable performance of heavy-duty trucks, contributing to the overall functionality and durability of the engine system.

Basic Concepts of Crankshaft Pulleys

A crankshaft pulley, also known as a harmonic balancer, is a toothed wheel attached to the front of an engine’s crankshaft. Its primary function is to drive engine accessories through a series of belts. These accessories may include the alternator, water pump, and air conditioning compressor. The pulley ensures that these components receive the necessary rotational force to operate effectively. Additionally, the crankshaft pulley helps to reduce vibrations within the engine by balancing the crankshaft’s rotational forces 1.

Purpose of the 3326140 Crankshaft Pulley

The 3326140 Crankshaft Pulley plays a role in the operation of a truck by driving various engine accessories and maintaining proper belt tension. It ensures that accessories such as the alternator and water pump receive consistent power, which is crucial for the engine’s performance. By maintaining belt tension, the pulley helps to prevent belt slippage and ensures that accessories operate efficiently.

Key Features

The design and construction of the 3326140 Crankshaft Pulley include several features that enhance its performance and durability. The pulley is typically made from a combination of metal and rubber, which provides both strength and flexibility. Its balanced design helps to minimize vibrations, contributing to a smoother engine operation. Additionally, the pulley may feature unique design elements such as a dampening system to further reduce vibrations and enhance durability.

Benefits

The 3326140 Crankshaft Pulley offers several advantages. It contributes to improved engine efficiency by ensuring that engine accessories receive consistent power. This can lead to better overall performance and fuel efficiency. Additionally, the pulley’s design helps to reduce wear on driven components, extending their lifespan. Its robust construction and balanced design enhance reliability, making it suitable for heavy-duty applications.

Installation and Compatibility

Proper installation of the 3326140 Crankshaft Pulley is important for ensuring optimal performance and longevity. Installation procedures may vary depending on the specific engine and vehicle model. It is important to follow manufacturer guidelines to ensure that the pulley is correctly aligned and secured. This may involve using specific tools and following a precise sequence of steps to avoid damage to the pulley or other engine components.

Troubleshooting and Maintenance

Common issues associated with the 3326140 Crankshaft Pulley may include belt slippage, noise, or vibration. Regular inspection and maintenance can help to identify and address these issues before they lead to more significant problems. Maintenance practices may include checking belt tension, inspecting the pulley for signs of wear or damage, and ensuring that all connections are secure. Addressing issues promptly can help to prevent premature failure and extend the lifespan of the pulley 2.

Performance Enhancements

Potential upgrades or modifications to the 3326140 Crankshaft Pulley may include adjustments to pulley sizing or material upgrades. These enhancements can improve engine performance by optimizing the transfer of rotational force to engine accessories. For example, a larger pulley may increase the speed at which accessories operate, while a material upgrade may enhance durability and reduce vibrations. It is important to consider the specific requirements of the engine and vehicle when making these modifications.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long history of innovation and quality in the automotive and heavy-duty truck industries. The company offers a wide range of products, including engines, powertrains, and aftermarket parts, and is known for its commitment to customer satisfaction and technological advancement.

Cummins Crankshaft Pulley Part 3326140 Compatibility

The Cummins crankshaft pulley part number 3326140 is designed to fit a variety of engines, ensuring compatibility and reliability across different models. This part is integral to the engine’s operation, facilitating the transfer of power from the crankshaft to the engine’s accessory components.

Engine Compatibility

-

NH/NT 855 Engines: The 3326140 crankshaft pulley is engineered to fit seamlessly with the NH/NT 855 engines, providing a robust connection that ensures smooth operation and efficient power transmission.

-

QSNT14 CM876 N102 Engines: This crankshaft pulley is also compatible with the QSNT14 CM876 N102 engines. Its design ensures that it can handle the specific demands of these engines, maintaining the integrity of the power transfer system.

By ensuring that the 3326140 crankshaft pulley is compatible with these engines, Cummins maintains a high standard of quality and reliability, making it a trusted choice for engine maintenance and repair.

Understanding the Integration of Part 3326140 Crankshaft Pulley in Engine Systems

Part 3326140, the Crankshaft Pulley, is a vital component in the synchronization and operation of various engine systems. Its primary function is to transfer rotational force from the crankshaft to other engine components, ensuring smooth and efficient operation.

Interaction with Damper and Pulley Systems

The Crankshaft Pulley works in conjunction with the damper and pulley system to maintain consistent rotational speed. This system includes a damper, which is essential for absorbing vibrations and reducing stress on the engine components. The damper, often integrated within the pulley assembly, helps in smoothing out the crankshaft’s rotation, leading to a more stable and reliable engine performance.

Role in Vibration Management

One of the significant roles of the Crankshaft Pulley is its interaction with the vibration damper. The vibration damper is designed to mitigate the harmonic vibrations produced by the engine’s operation. By effectively managing these vibrations, the Crankshaft Pulley contributes to the longevity and reliability of the engine components, reducing wear and tear.

Ensuring Smooth Operation

The integration of the Crankshaft Pulley with the damper and pulley system is essential for the smooth operation of the engine. This component ensures that the rotational force is evenly distributed, minimizing the risk of mechanical failures and enhancing the overall efficiency of the engine.

Conclusion

In summary, the Crankshaft Pulley (Part 3326140) plays a significant role in the engine’s damper and pulley system, working alongside the vibration damper to ensure smooth, efficient, and reliable engine performance. Its design and features contribute to the overall efficiency and durability of heavy-duty truck engines, making it a critical component for maintaining optimal engine operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.