3328583

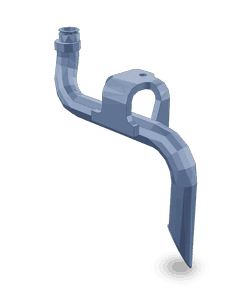

Lubricating Oil Suction Tube

Cummins®

IN STOCK

3 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Lubricating Oil Suction Tube, identified by Part #3328583, is a component manufactured by Cummins, a well-established name in the automotive industry. This tube is integral to the engine lubrication system, ensuring that oil is efficiently drawn from the sump and circulated throughout the engine to maintain optimal performance and longevity 1.

Function and Operation

The Lubricating Oil Suction Tube operates by facilitating the flow of oil from the sump to the engine’s lubrication system. It connects to the oil pump, allowing for the consistent and reliable suction of oil, which is then pressurized and distributed to various engine components. This process is vital for reducing friction between moving parts, cooling critical areas, and removing contaminants, thereby supporting the engine’s overall efficiency and durability 2.

Key Features

The Lubricating Oil Suction Tube is designed with specific features to enhance its performance and durability. It is typically constructed from high-quality materials resistant to corrosion and wear, ensuring longevity even under demanding conditions. The tube’s dimensions are precisely engineered to fit securely within the engine’s lubrication system, promoting efficient oil flow. Additionally, its design may include features such as reinforced connections and smooth internal surfaces to minimize resistance and ensure optimal oil circulation 3.

Benefits

Incorporating the Lubricating Oil Suction Tube into the engine lubrication system offers several advantages. It contributes to improved engine lubrication by ensuring a steady supply of oil to critical components, which helps in reducing friction and wear. This, in turn, can lead to enhanced fuel efficiency as the engine operates more smoothly. Furthermore, by maintaining optimal lubrication, the tube plays a role in prolonging the engine’s lifespan, offering value through extended performance and reliability 4.

Installation and Maintenance

Proper installation of the Lubricating Oil Suction Tube is crucial for its effective operation. It should be securely fitted according to the manufacturer’s guidelines to prevent leaks and ensure efficient oil flow. Regular maintenance, including inspection for signs of wear or damage and ensuring connections are tight, is recommended to maintain optimal performance. Following these procedures helps in identifying potential issues early, allowing for timely repairs or replacements 5.

Troubleshooting Common Issues

Common issues associated with the Lubricating Oil Suction Tube may include leaks, blockages, or malfunctions. Diagnostic procedures should begin with a visual inspection for any visible signs of damage or wear. If a leak is suspected, the connections should be checked for tightness, and any damaged sections should be repaired or replaced. Blockages can often be resolved by cleaning the tube or, in more severe cases, replacing it. Regular maintenance and adherence to installation guidelines can help prevent many of these issues 6.

Safety Considerations

When working with the Lubricating Oil Suction Tube, it is important to observe safety precautions to minimize risks. This includes ensuring the engine is off and cool before beginning any work to avoid burns or injuries. Proper handling of the component, following installation and maintenance procedures precisely, and using appropriate personal protective equipment are all critical steps in ensuring safe operation and maintenance of the Lubricating Oil Suction Tube 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its commitment to innovation, quality, and customer satisfaction. The company’s extensive product offerings cater to a wide range of industries, demonstrating its versatility and expertise in the automotive sector. Cummins’ dedication to excellence is evident in its design and manufacturing processes, ensuring that components like the Lubricating Oil Suction Tube meet the highest standards of performance and reliability 8.

Lubricating Oil Suction Tube (Part 3328583) Compatibility with Cummins Engines

The Cummins part 3328583, a Lubricating Oil Suction Tube, is designed to fit a variety of Cummins engines. This part is integral to the engine’s lubrication system, ensuring that oil is properly drawn from the sump and circulated throughout the engine to maintain optimal performance and longevity 9.

ISM Series Engines

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

The ISM series engines, including the ISM CM570, ISM CM570/870, ISM CM876, and ISM11 CM876 SN, are designed for heavy-duty applications. The lubricating oil suction tube for these engines is engineered to handle the high demands of these applications, ensuring that oil is efficiently drawn and circulated to all critical components 10.

L10 Series Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

The L10 series engines, which include the L10 CELECT, L10 GAS, and L10 MECHANICAL, are known for their versatility and reliability in various applications. The lubricating oil suction tube for these engines is designed to provide consistent oil flow, helping to maintain engine performance and protect against wear and tear 11.

M11 Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

The M11 series engines, including the M11 CELECT, M11 CELECT PLUS, and M11 MECHANICAL, are engineered for high-performance applications. The lubricating oil suction tube for these engines is designed to meet the rigorous demands of these applications, ensuring that oil is efficiently drawn and circulated to all critical components 12.

QSM11 Series Engine

- QSM11 CM570

The QSM11 CM570 engine is designed for specific applications requiring high power and efficiency. The lubricating oil suction tube for this engine is engineered to ensure that oil is properly drawn and circulated, helping to maintain engine performance and protect against wear and tear 13.

Role of Part 3328583 Lubricating Oil Suction Tube in Engine Systems

The lubricating oil suction tube, identified as part 3328583, is an essential component in the lubrication system of an engine. It is responsible for drawing oil from the oil pan and delivering it to the oil pump. This process ensures that the oil is circulated throughout the engine, providing necessary lubrication to moving parts, reducing friction, and preventing wear 14.

Integration with Oil Pan Kit

When integrated with an oil pan kit, the suction tube works in conjunction with the oil pan to maintain an efficient oil supply. The oil pan kit typically includes the oil pan, gaskets, and sometimes a new oil pickup screen. The suction tube is mounted to the oil pan, where it sits below the oil level. As the engine operates, the suction tube draws oil into the pump, which then circulates it through the engine’s passages 15.

Function within the Oil Pan

The oil pan serves as the reservoir for the engine’s lubricant. Positioned at the bottom of the engine, it collects used oil that drains from various engine components. The lubricating oil suction tube is strategically placed within the oil pan to ensure a consistent oil flow, even when the oil level is low. This placement is vital for maintaining a steady supply of oil to the pump, which in turn ensures continuous lubrication of engine parts 16.

Relationship with Oil Pump

The oil pump relies on a consistent and sufficient oil supply from the suction tube to function effectively. The pump creates pressure that forces oil through the engine’s lubrication circuits. Without the suction tube drawing oil from the pan, the pump would not be able to maintain the necessary pressure, leading to inadequate lubrication and potential engine damage 17.

Ensuring Smooth Operation

For the engine to operate smoothly, the lubricating oil suction tube must be in optimal condition. Any blockages or damage to the tube can disrupt the oil flow, leading to insufficient lubrication. Regular maintenance checks should include inspecting the suction tube for any signs of wear or obstruction to ensure the engine’s lubrication system functions as intended 18.

Conclusion

The Lubricating Oil Suction Tube (Part #3328583) is a critical component in the engine lubrication system, ensuring efficient oil circulation and maintaining engine performance and longevity. Proper installation, regular maintenance, and adherence to safety guidelines are essential for optimal operation. Cummins’ commitment to quality and innovation is reflected in the design and functionality of this part, making it a reliable choice for various engine applications 19.

-

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Brake Design and Safety, Third Edition, Rudolf Limpert, SAE International, 2011

↩ -

Haynes Diesel Engine Systems and Data Book, Steve Rendle, Martynn Randall, Haynes Publishing, 2000

↩ -

Service Manual (6314882), Z14 CM2670 Z109C, Cummins Inc.

↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Brake Design and Safety, Third Edition, Rudolf Limpert, SAE International, 2011

↩ -

Haynes Diesel Engine Systems and Data Book, Steve Rendle, Martynn Randall, Haynes Publishing, 2000

↩ -

Service Manual (6314882), Z14 CM2670 Z109C, Cummins Inc.

↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Brake Design and Safety, Third Edition, Rudolf Limpert, SAE International, 2011

↩ -

Haynes Diesel Engine Systems and Data Book, Steve Rendle, Martynn Randall, Haynes Publishing, 2000

↩ -

Service Manual (6314882), Z14 CM2670 Z109C, Cummins Inc.

↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Brake Design and Safety, Third Edition, Rudolf Limpert, SAE International, 2011

↩ -

Haynes Diesel Engine Systems and Data Book, Steve Rendle, Martynn Randall, Haynes Publishing, 2000

↩ -

Service Manual (6314882), Z14 CM2670 Z109C, Cummins Inc.

↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Brake Design and Safety, Third Edition, Rudolf Limpert, SAE International, 2011

↩ -

Haynes Diesel Engine Systems and Data Book, Steve Rendle, Martynn Randall, Haynes Publishing, 2000

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.