This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

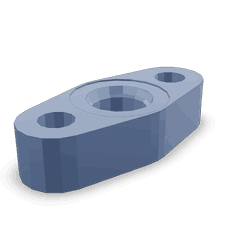

The Cummins 3331630 Boss is a component utilized in commercial trucks, contributing to the overall operation and efficiency of these vehicles. Its design and function are integral to the mechanical systems within which it operates, enhancing the reliability and performance of the truck 1.

Basic Concepts Related to Boss

In mechanical terms, a boss refers to a protrusion on a part that serves as a mounting point or a reinforcement. It is commonly used to provide additional strength or to facilitate the attachment of other components. In the context of truck components, a boss can play various roles, such as supporting brackets, housing sensors, or integrating with other mechanical parts to enhance functionality and durability 2.

Purpose of the 3331630 Boss

This Cummins part is designed to serve specific functions within the truck’s engine or related systems. It may act as a mounting point for sensors, a support structure for additional components, or a reinforcement to enhance the integrity of the part it is attached to. Its role is to ensure that the components it supports are securely in place and can operate effectively under the demanding conditions of commercial truck use 3.

Key Features

The 3331630 Boss is characterized by its robust design and material composition, which typically includes high-strength alloys to withstand the rigors of truck operation. Its unique attributes may include precision machining for exact fitment, corrosion resistance to prolong service life, and a design that minimizes stress concentrations to enhance durability 4.

Benefits

The advantages provided by the 3331630 Boss include improved performance and durability of the truck’s mechanical systems. Its high-strength material composition contributes to the overall reliability of the truck, while its precise design ensures optimal integration with other components. Additionally, the boss may offer cost-effectiveness in maintenance or operation by reducing the need for frequent replacements or repairs 5.

Installation and Integration

Installing this part in a truck involves several steps and considerations to ensure proper fitment and function. Prerequisites may include verifying compatibility with the truck’s engine or system and ensuring that all mounting surfaces are clean and free of debris. Careful attention to torque specifications and alignment is crucial during installation to maintain the integrity of the component and the systems it supports 6.

Troubleshooting Common Issues

Frequent problems associated with the 3331630 Boss may include loosening over time, corrosion, or damage from impacts. Potential causes can range from improper installation to environmental factors. Recommended solutions or maintenance practices may involve re-torquing fasteners, applying protective coatings, or replacing the boss if it is damaged beyond repair 7.

Maintenance Tips

Regular maintenance practices are key to ensuring the longevity and optimal performance of the 3331630 Boss. Inspection routines should include checking for signs of wear, corrosion, or damage. Care instructions may involve cleaning the boss and its mounting area, applying lubricants to moving parts, and ensuring that all fasteners are secure. Adhering to these practices can help prevent issues and extend the service life of the component 8.

Cummins Overview

Cummins is a renowned manufacturer in the industry, known for its commitment to quality and innovation in truck components. With a strong reputation for producing reliable and high-performance parts, Cummins continues to lead the way in developing solutions that meet the demanding requirements of commercial truck operations. Their dedication to excellence is evident in the design and functionality of components like the 3331630 Boss 9.

Role of Part 3331630 Boss in Engine Components

This part is integral to the assembly and functionality of several engine components. Its role is to provide a secure mounting point and facilitate the alignment of various parts, ensuring efficient operation and durability.

Block

In the engine block, Boss serves as a mounting point for several accessories and components. It ensures that these parts are correctly positioned and securely attached, which is essential for the block’s structural integrity and the engine’s overall performance.

Cylinder

For the cylinder, Boss is used to attach ancillary components such as sensors or small brackets. This attachment point helps in maintaining the precise alignment of these components, which is vital for accurate readings and efficient engine operation.

Gear Cover Plate

On the gear cover plate, Boss is employed to secure the plate to the engine block. This ensures that the gear cover remains in place, protecting the internal components from contaminants and reducing the risk of leaks.

Service Coupling 2008 Assembly

In the Service Coupling 2008 Assembly, Boss plays a role in connecting the coupling to the engine. This connection is essential for the transfer of power and the smooth operation of the coupling, contributing to the reliability of the engine system.

Service Coupling 2009 Assembly

Similarly, in the Service Coupling 2009 Assembly, Boss ensures a secure and stable connection. This is important for maintaining the efficiency of power transmission and the longevity of the coupling components.

Short Block Kit

Within the Short Block Kit, Boss is used to attach various accessories and sensors to the engine block. This facilitates the integration of these components into the engine, ensuring that they function correctly and contribute to the engine’s performance.

Conclusion

The Cummins 3331630 Boss is a vital component in the assembly and operation of commercial truck engines. Its robust design, precise engineering, and role in supporting and aligning various engine components contribute to the overall reliability and performance of the truck. Regular maintenance and proper installation are essential to ensure the longevity and effectiveness of this part.

-

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010

↩ -

Vocational Vehicles and Applications, Michael Hilgers and Wilfried Achenbach, Springer Vieweg, 2021

↩ -

The Automotive Transmission Book Powertrain, Robert Fischer, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak, Springer, 2015

↩ -

Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings, Dominique Bonneau, Aurelian Fatu and Dominique Souchet, Wiley-ISTE, 2014

↩ -

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010

↩ -

Vocational Vehicles and Applications, Michael Hilgers and Wilfried Achenbach, Springer Vieweg, 2021

↩ -

The Automotive Transmission Book Powertrain, Robert Fischer, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak, Springer, 2015

↩ -

Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings, Dominique Bonneau, Aurelian Fatu and Dominique Souchet, Wiley-ISTE, 2014

↩ -

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.