This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

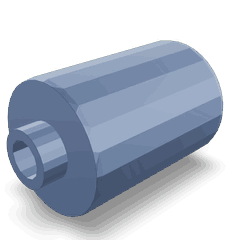

The Cummins 3352902 Vibration Isolator is a component designed to mitigate the transmission of vibrations from the engine or drivetrain to the truck’s frame and cabin. This isolator plays a role in enhancing the operational efficiency and comfort of heavy-duty trucks by reducing the impact of vibrations on both the vehicle’s structure and its occupants 1.

Basic Concepts of Vibration Isolators

Vibration isolators are devices used in mechanical systems to reduce the transmission of vibrations from a source to a destination. They function by absorbing or deflecting vibrational energy, thereby minimizing its impact on connected components. The principle of vibration isolation is based on the use of materials and designs that can absorb, dampen, or redirect vibrational forces. This is important for maintaining the integrity and performance of equipment, as excessive vibrations can lead to wear, fatigue, and potential failure of mechanical parts 2.

Purpose of the 3352902 Vibration Isolator

The 3352902 Vibration Isolator is specifically designed to play a role in the operation of a truck by reducing the vibrations transmitted from the engine or drivetrain. By doing so, it helps in maintaining a stable and comfortable environment within the truck’s cabin, as well as protecting the truck’s frame and other components from the adverse effects of engine vibrations.

Key Features

The 3352902 Vibration Isolator features a design that incorporates materials known for their vibration-absorbing properties. Its construction includes robust materials that enhance its performance and durability under the demanding conditions typical of heavy-duty truck operations. Unique attributes of this isolator may include its ability to withstand high levels of stress and its design for easy integration into truck systems.

Benefits of Using the 3352902 Vibration Isolator

Incorporating the 3352902 Vibration Isolator into truck designs offers several advantages. These include improved ride comfort for both the driver and passengers, reduced wear and tear on truck components due to minimized vibrations, and an overall enhanced driving experience. The isolator contributes to the longevity of the truck’s mechanical systems by mitigating the effects of vibrational stress.

Installation and Integration

Proper installation of the 3352902 Vibration Isolator is important for its effective performance. Guidelines for installation include ensuring compatibility with the specific truck model, correct mounting, and alignment to achieve optimal vibration isolation. Attention to these details during installation helps in maximizing the benefits of the isolator.

Maintenance and Troubleshooting

Routine maintenance practices are recommended to ensure the longevity and effectiveness of the 3352902 Vibration Isolator. This may include regular inspections for signs of wear or damage and addressing any issues promptly to prevent further complications. Common problems that may arise include reduced effectiveness over time due to material fatigue, which can be addressed through proper maintenance and, if necessary, replacement.

Cummins Corporation

Cummins Inc. is a well-established manufacturer in the automotive and heavy-duty truck industry, known for its wide range of products and commitment to innovation and quality. The company’s reputation is built on a history of delivering reliable and high-performance components, including the 3352902 Vibration Isolator, which reflects Cummins’ dedication to enhancing the efficiency and comfort of heavy-duty trucks 3.

Vibration Isolator 3352902 Compatibility with Cummins Engines

The Cummins Vibration Isolator part number 3352902 is designed to be compatible with a range of Cummins engines, providing effective vibration management and enhancing the overall performance and longevity of the engine systems. Here is a detailed look at the compatibility of this part with various Cummins engines:

4B3.9 and 6B5.9 Engines

The 3352902 Vibration Isolator is suitable for use with the 4B3.9 and 6B5.9 engines. These engines are known for their robust performance and reliability, and the vibration isolator helps to mitigate the operational stresses that can lead to wear and tear.

6C8.3 and C8.3 G Engines

For the 6C8.3 and C8.3 G engines, the 3352902 Vibration Isolator is an important component. These engines benefit from the isolator’s ability to reduce vibrations, which can significantly extend engine life and improve operational efficiency.

C GAS PLUS CM556 and ISC CM554 Engines

The 3352902 part is also compatible with the C GAS PLUS CM556 and ISC CM554 engines. These engines are often used in various applications, and the vibration isolator plays a role in maintaining smooth operation by minimizing the impact of vibrations.

ISC CM850 and ISL CM554 Engines

The ISC CM850 and ISL CM554 engines are designed for heavy-duty applications, and the 3352902 Vibration Isolator is a key component in these setups. It helps to absorb and dissipate vibrations, protecting the engine from potential damage and ensuring consistent performance.

ISL9 CM2150 SN and QSC8.3 CM554 Engines

The ISL9 CM2150 SN and QSC8.3 CM554 engines are part of Cummins’ lineup of high-performance engines. The 3352902 Vibration Isolator is engineered to work seamlessly with these engines, providing the necessary vibration management to maintain optimal engine conditions.

QSC8.3 CM850 (CM2850) and QSL9 CM554 and QSL9 CM850 (CM2850) Engines

Lastly, the 3352902 Vibration Isolator is compatible with the QSC8.3 CM850 (CM2850), QSL9 CM554, and QSL9 CM850 (CM2850) engines. These engines are used in demanding environments, and the isolator’s role in reducing vibrations is important for their sustained performance and durability.

By integrating the 3352902 Vibration Isolator into these engines, operators can expect enhanced reliability, reduced maintenance needs, and improved overall engine performance.

Role of Part 3352902 Vibration Isolator in Engine Systems

The part 3352902 Vibration Isolator is a component in mitigating the transmission of vibrations from the engine to other parts of the vehicle. When integrated with the Front Engine Support and Support components, it significantly enhances the overall stability and performance of the engine system.

Integration with Front Engine Support

The Front Engine Support is designed to securely hold the engine in place, absorbing some of the vibrational forces generated during operation. The addition of the 3352902 Vibration Isolator to this system further reduces the vibrations that reach the support structure. This results in a more stable engine mounting, which in turn leads to improved durability of the Front Engine Support and reduced wear on the mounting points.

Interaction with Support Components

In conjunction with other Support components, the 3352902 Vibration Isolator plays a role in maintaining the structural integrity of the engine assembly. By isolating vibrations, it prevents the transfer of excessive vibrational energy to adjacent components, such as the chassis and body of the vehicle. This not only enhances the longevity of the support components but also contributes to a smoother driving experience.

Contribution to Front Engine Stability

The Front Engine itself benefits from the presence of the 3352902 Vibration Isolator. By minimizing vibrations, the isolator helps in maintaining optimal engine performance and efficiency. It ensures that the engine operates within its designed parameters, reducing the likelihood of premature wear and potential failures.

Conclusion

In summary, the 3352902 Vibration Isolator works in harmony with the Front Engine Support, Support components, and the Front Engine to create a more stable, efficient, and durable engine system. Its integration into Cummins engines enhances reliability, reduces maintenance needs, and improves overall engine performance.

-

Van Gelder, Kirk T. Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning, 2018.

↩ -

Robert Bosch GmbH. Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg, 2007.

↩ -

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.