This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbo Oil Drain Tube, part number 3352930, manufactured by Cummins, is a component designed to facilitate the maintenance and operation of heavy-duty trucks. Cummins, a well-established name in the automotive industry, particularly in diesel engines and related components, ensures that this part meets the rigorous demands of heavy-duty applications.

Basic Concepts of Turbo Oil Drain Tubes

A Turbo Oil Drain Tube is an integral part of the turbocharger system. Its primary function is to drain oil from the turbocharger, preventing oil buildup that could impede the turbocharger’s efficiency and longevity. By ensuring that excess oil is removed, the tube helps maintain the turbocharger’s performance, contributing to the overall efficiency and durability of the engine 1.

Purpose of the Turbo Oil Drain Tube

The Turbo Oil Drain Tube plays a role in the operation of a truck by facilitating the drainage of oil from the turbocharger. This function is vital for preventing oil accumulation, which can lead to decreased turbocharger efficiency and potential damage. By ensuring that oil is efficiently drained, the tube supports the turbocharger’s optimal operation, thereby enhancing the engine’s performance and reliability.

Key Features

The Turbo Oil Drain Tube is designed with several features that enhance its performance and durability. It is constructed from high-quality materials to withstand the harsh conditions of heavy-duty truck operations. The tube’s design ensures a secure fit and efficient oil drainage, while its robust construction contributes to its longevity. Additionally, the tube may include unique attributes such as corrosion-resistant coatings or reinforced connections to further improve its performance in demanding environments.

Benefits

Using the Turbo Oil Drain Tube offers several benefits. It contributes to improved turbocharger efficiency by ensuring that oil is effectively drained, reducing the risk of oil buildup. This, in turn, can lead to reduced maintenance requirements, as the turbocharger is less likely to suffer from oil-related issues. Furthermore, the enhanced performance of the turbocharger can result in better overall engine performance, making the truck more reliable and efficient.

Installation Process

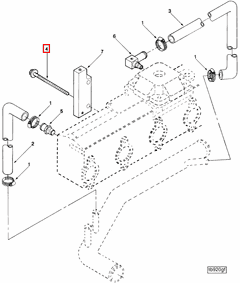

Installing the Turbo Oil Drain Tube requires careful attention to ensure correct fitting and optimal performance. The process involves several steps, including preparing the turbocharger for the new tube, aligning the tube with the turbocharger’s oil drain port, and securing it in place. Tools such as wrenches and sealant may be required, and it is important to follow manufacturer guidelines to ensure a proper installation. Careful consideration should be given to the tube’s orientation and connection to prevent leaks and ensure efficient oil drainage.

Maintenance Tips

To ensure the optimal performance of the Turbo Oil Drain Tube, regular maintenance is recommended. This includes inspecting the tube for signs of wear or damage at regular intervals, cleaning the tube and its connections to prevent blockages, and checking for proper alignment and secure fitting. If any issues are detected, such as leaks or significant wear, the tube should be replaced to maintain the turbocharger’s efficiency and the engine’s performance.

Troubleshooting Common Issues

Common problems associated with Turbo Oil Drain Tubes include leaks and blockages. Leaks may occur due to improper installation, wear, or damage to the tube, while blockages can result from debris or oil buildup. To troubleshoot these issues, inspect the tube and its connections for signs of damage or misalignment, clean the tube and connections to remove any debris, and ensure that the tube is securely fitted. If problems persist, replacement of the tube may be necessary to restore proper function.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the automotive industry, with a strong reputation for producing high-quality diesel engines and related components. Founded in 1919, Cummins has a long history of innovation and excellence, offering a wide range of products designed to meet the demands of various applications, from heavy-duty trucks to industrial equipment. The company’s commitment to quality and performance is evident in its extensive product range, which includes engines, filtration systems, and turbochargers, among others 2.

Turbo Oil Drain Tube (Part 3352930) Compatibility with Cummins Engines

The Turbo Oil Drain Tube, identified by part number 3352930 and manufactured by Cummins, is a critical component in the maintenance and operation of certain Cummins engine models. This part is designed to facilitate the drainage of oil from the turbocharger, ensuring that the system operates efficiently and without contamination.

Compatibility with Specific Engine Models

The Turbo Oil Drain Tube (3352930) is compatible with the following Cummins engine models:

- 6C8.3

This part is integral to the proper functioning of the turbocharger system, ensuring that oil is effectively drained and does not accumulate, which could lead to performance issues or damage.

Grouping of Compatible Engines

While the Turbo Oil Drain Tube (3352930) is specifically designed for the 6C8.3 engine, it is essential to note that Cummins often designs parts to be compatible across a range of similar engine models. This design philosophy ensures that maintenance and repair processes are streamlined, and parts are readily available for multiple engine types.

By ensuring that the Turbo Oil Drain Tube (3352930) is correctly installed and maintained, engine operators can enhance the longevity and reliability of their Cummins engines.

Role of Part 3352930 Turbo Oil Drain Tube in Engine Systems

The Turbo Oil Drain Tube, identified by part number 3352930, is an essential component in the maintenance and operation of engine systems, particularly those equipped with turbochargers. Its primary function is to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and that oil does not accumulate to problematic levels.

Integration with Turbocharger

In turbocharged engine systems, the turbocharger operates at high speeds and temperatures. The Turbo Oil Drain Tube is strategically positioned to connect the turbocharger to the engine’s oil return system. This connection allows for the continuous circulation of oil, which is vital for cooling and lubricating the turbocharger’s moving parts. By efficiently draining excess oil, the tube helps maintain optimal oil levels within the turbocharger, thereby enhancing its performance and longevity 3.

Interaction with Plumbing

The Turbo Oil Drain Tube is an integral part of the engine’s oil management plumbing. It is designed to work in conjunction with other oil lines and return paths to ensure a seamless flow of oil throughout the system. The tube’s precise fitting and sealing properties are essential to prevent oil leaks, which could lead to reduced lubrication efficiency and potential engine damage. Its role in the plumbing system is to provide a reliable pathway for oil to travel from the turbocharger back to the sump or oil pan, where it can be recirculated.

Overall System Contribution

By effectively managing oil drainage, the Turbo Oil Drain Tube contributes to the overall stability and reliability of the engine system. It ensures that the turbocharger receives consistent lubrication, which is necessary for its high-speed operation. Additionally, the tube’s role in the oil return system helps maintain proper oil pressure and temperature within the engine, supporting the efficient operation of other components as well.

Conclusion

The Turbo Oil Drain Tube, part number 3352930, is a critical component in the maintenance and operation of heavy-duty trucks, particularly those equipped with Cummins engines. By facilitating the efficient drainage of oil from the turbocharger, this part ensures that the turbocharger operates at optimal efficiency and longevity. Regular maintenance and proper installation are essential to maximize the benefits of this component, contributing to the overall performance and reliability of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.