This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

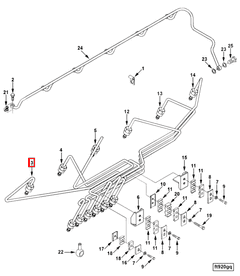

The Cummins Injector Fuel Supply Tube, identified by part number 3354590, is a component integral to the fuel system of heavy-duty trucks. Manufactured by Cummins, a renowned name in the automotive industry, this part ensures the efficient delivery of fuel to the injectors, playing a significant role in the overall performance and reliability of the engine 1.

Basic Concepts and Functionality

The Injector Fuel Supply Tube operates on fundamental principles of fluid dynamics within the fuel injection system. It serves as a conduit that transports fuel from the fuel tank or reservoir to the injectors. The tube’s design allows for precise fuel delivery, ensuring that the injectors receive a consistent and adequate supply of fuel under varying engine conditions 2.

Purpose and Role in Truck Operation

The Injector Fuel Supply Tube is specifically designed to enhance the fuel delivery efficiency in heavy-duty truck engines. By providing a direct and unobstructed path for fuel to travel from the supply source to the injectors, it contributes to the engine’s performance by ensuring that the injectors operate with optimal fuel pressure and flow. This, in turn, supports the engine’s power output and efficiency 3.

Key Features

The Injector Fuel Supply Tube boasts several key features that enhance its functionality. Constructed from durable materials, it is designed to withstand the high pressures and temperatures within the fuel system. Its design includes precise fittings and connections that ensure a secure and leak-free installation. Additionally, the tube may incorporate features that reduce noise and vibration, contributing to a smoother engine operation 4.

Benefits

The advantages of the Injector Fuel Supply Tube include improved fuel atomization, which leads to more efficient combustion and enhanced engine performance. By ensuring a consistent fuel supply, it also contributes to reduced emissions, aligning with environmental standards. Furthermore, its robust construction and design elements support longevity and reliability in demanding operating conditions 5.

Installation and Integration

Proper installation of the Injector Fuel Supply Tube requires attention to detail to ensure it fits correctly within the fuel system. Preparations may include cleaning the installation area and inspecting the tube for any damage. Tools such as torque wrenches may be necessary to secure fittings properly. Following the manufacturer’s guidelines for installation ensures that the tube is integrated effectively into the system 6.

Troubleshooting and Maintenance

Identifying common issues with the Injector Fuel Supply Tube involves checking for leaks, unusual noises, or performance drops in the engine. Diagnostic procedures may include visual inspections and pressure tests to assess the tube’s condition. Regular maintenance practices, such as cleaning and inspecting the tube for wear, help ensure optimal performance and extend its service life 7.

Manufacturer - Cummins

Cummins, the manufacturer of the Injector Fuel Supply Tube, has a long-standing reputation in the automotive industry for producing high-quality components. With a history of innovation and commitment to excellence, Cummins continues to be a trusted name among professionals and enthusiasts alike, known for their dedication to enhancing engine performance and reliability 8.

Compatibility with Cummins Engines

The Injector Fuel Supply Tube (3354590) is specifically engineered to fit various Cummins engines, ensuring a precise and secure connection. Here are the engines and engine groups where this part is applicable:

-

6C8.3: This engine is part of the Cummins C-Series lineup, known for its robust design and reliability in heavy-duty applications. The 3354590 part is integral to the fuel system of the 6C8.3 engine, facilitating the smooth delivery of fuel to the injectors.

-

Other Cummins Engines: While the 3354590 part is prominently used in the 6C8.3 engine, it may also be compatible with other models within the Cummins engine family. Its design and specifications are tailored to meet the stringent requirements of Cummins’ fuel systems, ensuring compatibility across various engine types.

Importance of the Fuel Supply Tube

The Injector Fuel Supply Tube plays a pivotal role in the engine’s fuel delivery mechanism. It is responsible for:

- Maintaining Fuel Pressure: Ensuring that the fuel is delivered to the injectors at the correct pressure, which is crucial for efficient combustion.

- Preventing Leaks: Providing a secure and leak-free connection between the fuel pump and the injectors, which helps in maintaining the engine’s performance and reliability.

- Ensuring Fuel Flow: Guaranteeing a consistent and uninterrupted flow of fuel, which is essential for the engine’s smooth operation.

By integrating seamlessly with the engine’s fuel system, the Injector Fuel Supply Tube ensures that the engine operates at peak efficiency, reducing the likelihood of fuel-related issues and enhancing overall performance 9.

Role of Part 3354590 Injector Fuel Supply Tube in Engine Systems

The Injector Fuel Supply Tube, identified by part number 3354590, is an essential component in the fuel delivery system of an engine. This tube is responsible for transporting fuel from the fuel rail to the individual fuel injectors.

In the context of the fuel system, the Injector Fuel Supply Tube interfaces directly with the fuel rail, which is a pressurized conduit that distributes fuel to each injector. The tube ensures a consistent and reliable flow of fuel, which is vital for the injectors to operate efficiently.

The Injector Fuel Supply Tube also connects to the injectors themselves, which are responsible for spraying atomized fuel into the combustion chamber at precise intervals. This connection is part of the overall plumbing of the fuel system, ensuring that fuel is delivered under the correct pressure and at the right time.

Furthermore, the tube plays a role in maintaining the integrity of the fuel supply by preventing leaks and ensuring that fuel is not contaminated as it travels from the fuel rail to the injectors. This is particularly important in high-performance engines where fuel delivery precision can significantly affect engine performance and efficiency.

In summary, the Injector Fuel Supply Tube is a key element in the fuel delivery network, facilitating the smooth operation of the injectors and contributing to the overall performance of the engine 10.

Conclusion

The Cummins Injector Fuel Supply Tube (part number 3354590) is a vital component in the fuel delivery system of heavy-duty engines. Its role in ensuring efficient fuel delivery, maintaining fuel pressure, preventing leaks, and ensuring consistent fuel flow is crucial for the engine’s performance and reliability. The tube’s robust construction, precise design, and compatibility with various Cummins engines make it an indispensable part of the fuel system, contributing to the overall efficiency and longevity of the engine.

-

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩ -

P. A. Lakshminarayanan and Avinash Kumar, Design and Development of Heavy Duty Diesel Engines: A Handbook, Springer Nature, 2020.

↩ -

William B. Ribbens, Understanding Automotive Electronics, Elsevier Science, 2003.

↩ -

Cummins, C Command Connect and Connect Premier Marine Panel System PS102 and PS103, Bulletin Number 5411480, Master Repair Manual.

↩ -

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩ -

P. A. Lakshminarayanan and Avinash Kumar, Design and Development of Heavy Duty Diesel Engines: A Handbook, Springer Nature, 2020.

↩ -

William B. Ribbens, Understanding Automotive Electronics, Elsevier Science, 2003.

↩ -

Cummins, C Command Connect and Connect Premier Marine Panel System PS102 and PS103, Bulletin Number 5411480, Master Repair Manual.

↩ -

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩ -

P. A. Lakshminarayanan and Avinash Kumar, Design and Development of Heavy Duty Diesel Engines: A Handbook, Springer Nature, 2020.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.