This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

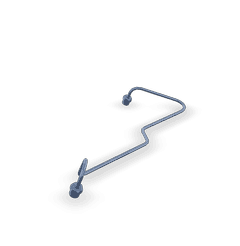

The Cummins Injector Fuel Supply Tube, identified by part number 3354593, is a critical component in the fuel delivery system of heavy-duty trucks. Manufactured by Cummins Inc., a leader in the automotive and heavy-duty truck industry, this part is designed to enhance the efficiency and performance of diesel engines. Its role in the fuel system underscores the importance of precision engineering and reliable component design in achieving optimal engine operation 1.

Basic Concepts of Injector Fuel Supply Tubes

An Injector Fuel Supply Tube is a conduit that facilitates the transfer of fuel from the fuel tank to the injectors within the engine. This tube plays a role in the fuel injection system by ensuring a consistent and precise delivery of fuel, which is vital for the combustion process 2. The efficiency of this component directly influences the overall performance of the engine, including its power output, fuel efficiency, and emissions levels.

Purpose and Role in Truck Operation

The Cummins Injector Fuel Supply Tube serves a specific purpose within the context of heavy-duty truck engines. It is responsible for delivering fuel to the injectors under the precise conditions required for optimal combustion. This delivery system impacts engine efficiency and performance by ensuring that fuel is supplied at the correct pressure and timing. The tube’s design and material contribute to maintaining the integrity of the fuel as it travels from the tank to the injectors, minimizing the risk of leaks or contamination 3.

Key Features

The Cummins Injector Fuel Supply Tube is characterized by several key features that enhance its functionality and durability. These include a robust material composition designed to withstand the high pressures and temperatures within the fuel system. The design elements of the tube, such as its precise diameter and length, are tailored to ensure efficient fuel flow. Additionally, any unique characteristics, such as reinforced sections or specialized coatings, contribute to the tube’s longevity and resistance to wear.

Benefits

Utilizing the Cummins Injector Fuel Supply Tube offers several benefits. It contributes to improved fuel delivery precision, which is crucial for maintaining engine performance and efficiency. Enhanced engine performance is a direct result of the tube’s ability to supply fuel consistently and accurately. Furthermore, the component may play a role in improving fuel efficiency and reducing emissions, aligning with broader industry goals for environmental sustainability.

Installation and Integration

Proper installation and integration of the Cummins Injector Fuel Supply Tube within the fuel system of a heavy-duty truck are vital for optimal performance. Guidelines for installation emphasize the importance of compatibility with various engine models to ensure seamless integration. Correct installation is crucial for maintaining the integrity of the fuel system and achieving the desired engine performance.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are recommended to address common issues related to the Injector Fuel Supply Tube. Signs of wear, leaks, or malfunctions should be monitored to prevent potential failures. Maintenance tips include periodic inspections for damage, ensuring secure connections, and replacing the tube if signs of degradation are observed. These practices contribute to the longevity and reliable operation of the component.

Compatibility with Cummins Engines

This fuel supply tube is designed to fit seamlessly with several Cummins engine models. Here are the engines where this part is applicable:

- 6C8.3: The injector fuel supply tube is integral to the 6C8.3 engine, ensuring that the fuel supply system operates smoothly. This engine is known for its robust design and reliability, often used in heavy-duty applications.

Installation and Functionality

The installation of the injector fuel supply tube in Cummins engines involves precise alignment and secure attachment to the fuel injectors. This ensures that there are no leaks or disruptions in the fuel delivery process. The tube is typically made from high-quality materials that can withstand the high pressures and temperatures within the engine.

Importance in Engine Performance

The injector fuel supply tube plays a pivotal role in the overall performance of the engine. It ensures that the fuel is delivered at the correct pressure and timing, which is crucial for combustion efficiency. Any issues with this part can lead to performance degradation, increased fuel consumption, and potential engine damage.

Maintenance and Replacement

Regular maintenance of the injector fuel supply tube is essential to prevent failures and ensure the longevity of the engine. Inspections should be conducted to check for any signs of wear, cracks, or leaks. If any issues are detected, the part should be replaced promptly to avoid further complications.

Conclusion

The Cummins Injector Fuel Supply Tube, part number 3354593, is a vital component in the fuel delivery system of various Cummins engines, including the 6C8.3. Its proper installation and maintenance are crucial for maintaining engine performance and efficiency. The tube’s role in ensuring precise fuel delivery, its compatibility with various engine models, and the importance of regular maintenance highlight its significance in the overall operation of heavy-duty trucks.

-

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩ -

Arora, Shashank, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi. Heavyduty Electric Vehicles: From Concept to Reality. Elsevier, 2021.

↩ -

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.