This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

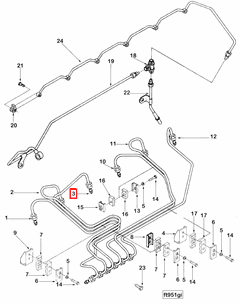

The Cummins Injector Fuel Supply Tube, identified by part number 3354917, is a component designed for use in the fuel delivery system of heavy-duty trucks. Its purpose is to facilitate the efficient transfer of fuel from the fuel tank to the injectors, ensuring that the engine receives the precise amount of fuel needed for optimal performance. The significance of this component lies in its role in maintaining the integrity and efficiency of the fuel delivery process, which is vital for the overall operation of the vehicle 1.

Basic Concepts of Injector Fuel Supply Tubes

Injector fuel supply tubes are integral to the fuel injection system, serving as conduits that deliver fuel from the fuel tank to the injectors. These tubes contribute to efficient fuel delivery by ensuring a consistent and reliable flow of fuel under varying engine conditions. They interact with other components such as the fuel pump, fuel filter, and injectors to maintain the desired fuel pressure and flow rate, which are essential for engine performance 2.

Purpose and Role in Truck Operation

The Cummins Injector Fuel Supply Tube (Part #3354917) plays a specific role in the operation of heavy-duty trucks by facilitating the delivery of fuel to the injectors. This component ensures that fuel is delivered at the correct pressure and volume, which directly impacts engine performance and efficiency. By maintaining a consistent fuel supply, the tube helps to optimize combustion, enhance power output, and improve fuel economy 3.

Key Features

The Cummins Injector Fuel Supply Tube is characterized by several key features that enhance its performance and durability. Its design is engineered to withstand the high pressures and temperatures associated with fuel delivery in heavy-duty engines. The materials used in its construction are selected for their strength, corrosion resistance, and ability to maintain structural integrity over time. Additionally, the tube may feature unique characteristics such as reinforced sections or specialized coatings to further improve its performance 4.

Benefits

The Cummins Injector Fuel Supply Tube offers several advantages that contribute to improved truck operation. These include enhanced fuel efficiency, as the tube ensures that fuel is delivered precisely when and where it is needed. This results in more efficient combustion and reduced fuel consumption. Additionally, the tube contributes to enhanced engine performance by maintaining consistent fuel pressure and flow, which supports optimal engine operation. Increased reliability is another benefit, as the durable construction of the tube helps to prevent leaks and failures, reducing the need for frequent maintenance 5.

Troubleshooting and Maintenance

Common issues that may arise with the Cummins Injector Fuel Supply Tube include leaks, blockages, and wear. Troubleshooting steps may involve inspecting the tube for visible damage, checking fuel pressure to ensure it meets specifications, and verifying that the tube is properly connected to other components. Regular maintenance practices to ensure optimal performance and longevity of the component include periodic inspection for signs of wear or corrosion, ensuring proper connections are maintained, and replacing the tube if significant degradation is observed 6.

Integration with Cummins Engines

The Cummins Injector Fuel Supply Tube is designed for integration into Cummins engine systems. Compatibility with various Cummins engine models is ensured through careful engineering and testing. Installation procedures typically involve connecting the tube to the fuel tank, fuel pump, and injectors, following manufacturer guidelines to ensure proper fit and function. Specific considerations for Cummins engine users may include ensuring that all connections are secure and that the tube is routed to avoid interference with other engine components 7.

Historical Development and Technological Advancements

The development of injector fuel supply tubes has seen significant technological advancements over the years. Early designs were relatively simple, but innovations in materials, manufacturing processes, and engineering have led to more robust and efficient components. Cummins has played a role in these advancements by introducing features such as reinforced sections, specialized coatings, and improved connection methods. These innovations have contributed to the enhanced performance and reliability of fuel delivery systems in heavy-duty trucks 8.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history dating back to 1919, Cummins has established a reputation for innovation, quality, and customer satisfaction. The company’s mission is to be the best in the world at powering a more prosperous world, and it achieves this through a commitment to developing advanced technologies and providing reliable, high-performance products. Cummins’ contributions to the automotive and engine manufacturing industries are significant, with a focus on delivering solutions that meet the evolving needs of customers around the world 9.

Cummins Injector Fuel Supply Tube (Part 3354917) Compatibility

The Cummins Injector Fuel Supply Tube, identified by part number 3354917, is a critical component in the fuel delivery system of various Cummins engines. This part is essential for maintaining the integrity and efficiency of the fuel supply to the injectors, ensuring optimal engine performance.

Engine Compatibility

-

6B5.9 Engine Series

- The 6B5.9 engine series benefits from the precise engineering of the Injector Fuel Supply Tube. This part is designed to fit seamlessly within the engine’s architecture, providing a reliable conduit for fuel from the supply line to the injectors.

- Ensuring that the Injector Fuel Supply Tube is correctly installed and in good condition is crucial for the 6B5.9 engines to operate efficiently and avoid potential fuel delivery issues.

-

Group Compatibility

- The Injector Fuel Supply Tube is also compatible with other Cummins engine groups that utilize similar fuel delivery systems. This ensures that the part can be effectively used across a range of engine models, providing a standardized solution for maintaining fuel supply integrity.

- The design and material of the Injector Fuel Supply Tube are optimized for durability and resistance to the harsh conditions within the engine compartment, ensuring long-term reliability and performance.

By understanding the compatibility of the Cummins Injector Fuel Supply Tube (part 3354917) with the 6B5.9 engine series and other relevant engine groups, technicians and engine operators can ensure that their engines maintain optimal performance and longevity.

Role of Part 3354917 Injector Fuel Supply Tube in Engine Systems

The Injector Fuel Supply Tube, identified by part number 3354917, is an integral component in the fuel delivery system of an engine. Its primary function is to transport pressurized fuel from the Bosch Fuel Pump Kit to the fuel injectors. This ensures a consistent and reliable fuel supply, which is essential for optimal engine performance.

Integration with Bosch Fuel Pump Kit

When integrated with the Bosch Fuel Pump Kit, the Injector Fuel Supply Tube acts as a conduit. The Bosch Fuel Pump Kit is responsible for pressurizing the fuel, and the Injector Fuel Supply Tube channels this pressurized fuel to the injectors. This seamless connection ensures that the fuel injectors receive a steady stream of pressurized fuel, which is vital for precise fuel delivery and combustion.

Plumbing and Fuel System Coordination

In the broader context of engine plumbing and the fuel system, the Injector Fuel Supply Tube plays a significant role. It is part of a network that includes fuel lines, filters, and regulators. The tube’s design and material are selected to withstand the high pressures and temperatures within the fuel system, ensuring durability and reliability.

Ensuring Efficient Fuel Injection

The efficiency of fuel injection is heavily dependent on the Injector Fuel Supply Tube. By providing a direct and unobstructed path for fuel, it helps maintain the integrity of the fuel pressure. This is particularly important in modern engines where fuel injectors operate under high pressure to achieve better atomization and combustion efficiency.

Contribution to Engine Performance

Ultimately, the Injector Fuel Supply Tube contributes to overall engine performance. By ensuring a consistent and pressurized fuel supply, it supports the engine’s ability to operate smoothly and efficiently. This is especially noticeable in high-performance engines where precise fuel delivery is paramount.

Conclusion

In summary, the Cummins Injector Fuel Supply Tube (part 3354917) is a key component in the fuel delivery system, working in conjunction with the Bosch Fuel Pump Kit and other fuel system components to ensure optimal engine performance. Its role in maintaining a consistent and reliable fuel supply is crucial for the efficient operation of heavy-duty trucks. Understanding its features, benefits, and integration with Cummins engines can help technicians and operators maintain engine performance and longevity.

-

Reif, Konrad, ed. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Gillespie, Thomas D. Fundamentals of Vehicle Dynamics. SAE International, 2021.

↩ -

Cummins Inc. F3.8 F102 Service Manual (4325984).

↩ -

Reif, Konrad, ed. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Cummins Inc. F3.8 F102 Service Manual (4325984).

↩ -

Gillespie, Thomas D. Fundamentals of Vehicle Dynamics. SAE International, 2021.

↩ -

Cummins Inc. Company Overview. Cummins Inc., 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.