This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Compressor Water Inlet Tube, identified by part number 3354930, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industries. This tube is integral to the operation of heavy-duty truck engines, facilitating efficient cooling processes that are vital for maintaining engine performance and longevity 1.

Function and Operation

The Compressor Water Inlet Tube operates within the engine system by directing coolant into the compressor. This process is part of the engine’s cooling mechanism, where the coolant absorbs heat from the compressor, thereby reducing the temperature of the compressed air before it enters the engine’s combustion chamber. The tube interacts with the engine’s cooling system, ensuring a consistent flow of coolant that aids in maintaining optimal operating temperatures 2.

Purpose of the Compressor Water Inlet Tube

The specific role of the Compressor Water Inlet Tube in a truck’s operation is to enhance engine efficiency and performance. By effectively managing the temperature of the compressed air, the tube contributes to more efficient combustion processes, which can lead to improved engine output and reduced wear on engine components 3.

Key Features

The Compressor Water Inlet Tube is characterized by several key features that enhance its functionality. It is typically made from durable materials that can withstand the high pressures and temperatures within the engine system. The design of the tube includes precise fittings and connections that ensure a secure and leak-free integration with the engine’s cooling system. Additionally, the tube may feature reinforced sections to handle the dynamic forces exerted during engine operation.

Benefits

The advantages provided by the Compressor Water Inlet Tube include improved engine cooling, which is crucial for maintaining engine efficiency and preventing overheating. The durable construction of the tube contributes to its longevity, reducing the need for frequent replacements. Furthermore, by ensuring optimal engine temperatures, the tube can potentially contribute to better fuel efficiency, as engines operate more efficiently within their designed temperature ranges.

Installation and Integration

Proper installation of the Compressor Water Inlet Tube involves several steps to ensure compatibility and effectiveness within the engine system. Prerequisites may include ensuring the engine is cool and the cooling system is drained to prevent coolant loss. Tools required for installation typically include wrenches for securing connections and a coolant pressure tester to verify the integrity of the system post-installation. Steps to ensure compatibility include verifying the tube’s dimensions and connection types match the engine’s specifications.

Maintenance and Care

To ensure the longevity and optimal performance of the Compressor Water Inlet Tube, routine maintenance practices are recommended. These include regular inspections for signs of wear or damage, such as cracks or leaks, and cleaning the tube and its connections to prevent buildup that could impede coolant flow. Inspection intervals may vary depending on the engine’s operating conditions but should be conducted as part of regular engine maintenance checks.

Troubleshooting Common Issues

Frequent problems associated with the Compressor Water Inlet Tube may include leaks, blockages, or damage from high pressure or temperature. Diagnostic tips for identifying these issues include checking for coolant leaks around the tube’s connections, monitoring engine temperature for signs of overheating, and inspecting the tube for physical damage. Potential solutions may involve repairing or replacing damaged sections, ensuring proper installation to prevent leaks, and maintaining the cooling system to prevent blockages.

Cummins Overview

Cummins is a renowned manufacturer within the automotive and heavy-duty truck industries, known for its wide range of engine and component products. With a history of innovation and quality, Cummins has established a reputation for producing reliable and high-performance parts. Their product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications.

Cummins Compressor Water Inlet Tube 3354930 Compatibility

The Cummins Compressor Water Inlet Tube part number 3354930 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is crucial for maintaining the efficiency of the engine’s cooling system, particularly in the compressor section.

Compatible Engines

- 6B5.9

- B5.9 G

These engines benefit from the precise engineering of the 3354930 part, which is tailored to meet the specific needs of these models. The compatibility ensures that the water inlet tube integrates smoothly with the engine’s existing components, providing a robust solution for water management within the compressor.

Role of Part 3354930 Compressor Water Inlet Tube in Engine Systems

The part 3354930 Compressor Water Inlet Tube is an essential component in the efficient operation of engine systems, particularly in those that require precise coolant management for optimal performance. This component is integral to the plumbing network that facilitates the flow of coolant to the compressor.

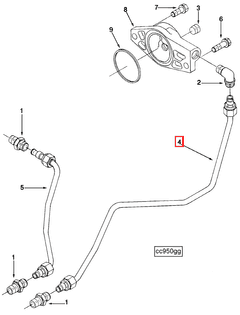

Integration with Plumbing Systems

In the context of engine plumbing, the Compressor Water Inlet Tube serves as a direct conduit for coolant. It is strategically positioned to ensure that the coolant is delivered at the right pressure and temperature to the compressor. This is achieved through its seamless integration with the plumbing system, which includes various pipes, hoses, and fittings designed to maintain a consistent coolant flow. The tube’s design allows for minimal resistance, ensuring that the coolant reaches the compressor without significant loss of pressure or temperature.

Interaction with Compressor Coolant Systems

When considering the compressor coolant system, the Compressor Water Inlet Tube plays a significant role in maintaining the thermal stability of the compressor. The tube is responsible for introducing coolant into the compressor at a precise location, typically near the point where the compressor experiences the highest thermal load. This targeted coolant delivery helps in dissipating heat effectively, thereby preventing overheating and potential damage to the compressor.

The tube’s connection to the compressor is designed to be secure and leak-proof, ensuring that the coolant is delivered consistently without any interruptions. This reliability is essential for the compressor’s longevity and efficiency, as even minor leaks can lead to significant performance issues.

Conclusion

In summary, the part 3354930 Compressor Water Inlet Tube is a vital component that ensures the smooth and efficient operation of engine systems by facilitating the precise delivery of coolant to the compressor. Its integration with the plumbing and compressor coolant systems underscores its importance in maintaining the overall performance and reliability of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.